KnuckleDuster

Well-Known Member

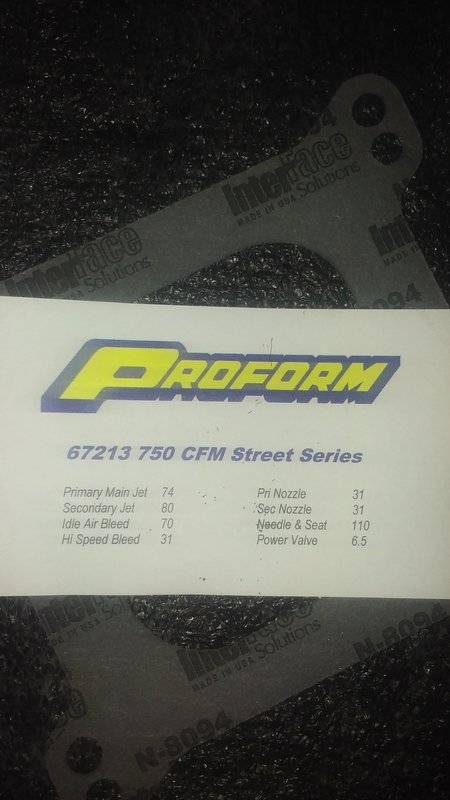

Getting ready to start tuning my Proform 750

Proform 67213: Street Series Mechanical Secondary Carburetor 750 cfm with Electric Choke | JEGS

I have couple of books for reference, but what are some other good sources for tuning info?

I am getting ready to order jets, gaskets, power valves, accelerator pump cams, and tools.

What do I really need and what do I not really need?

What gaskets? Holley non-stick, or other?

Is it necessary to buy specialized tools for jets and power valves?

What is your favorite fuel bowl catch can?

Any tips, tricks, or advice is welcome and appreciated!

Just looking to get anything I will need in one shot, and keep from wasting money on stuff I could do without.

Here is what I am planning to buy-

Holley 36-182: Double Pumper Kit | JEGS

Proform 67469: Carburetor Jet Installation Tool | JEGS

Proform 67454: Aluminum Power Valve Remover Tool | JEGS

Holley 20-12: Accelerator Pump Cam Assortment Includes 8 Different Cams | JEGS

JEGS Performance Products 15273: Anodized Float Bowl Catch Can 1-5/8" x 6" | JEGS

Proform 67213: Street Series Mechanical Secondary Carburetor 750 cfm with Electric Choke | JEGS

I have couple of books for reference, but what are some other good sources for tuning info?

I am getting ready to order jets, gaskets, power valves, accelerator pump cams, and tools.

What do I really need and what do I not really need?

What gaskets? Holley non-stick, or other?

Is it necessary to buy specialized tools for jets and power valves?

What is your favorite fuel bowl catch can?

Any tips, tricks, or advice is welcome and appreciated!

Just looking to get anything I will need in one shot, and keep from wasting money on stuff I could do without.

Here is what I am planning to buy-

Holley 36-182: Double Pumper Kit | JEGS

Proform 67469: Carburetor Jet Installation Tool | JEGS

Proform 67454: Aluminum Power Valve Remover Tool | JEGS

Holley 20-12: Accelerator Pump Cam Assortment Includes 8 Different Cams | JEGS

JEGS Performance Products 15273: Anodized Float Bowl Catch Can 1-5/8" x 6" | JEGS

Last edited: