I have a 65 Dart GT with a 318 4speed i bought a set of spitfires a few years ago had eng dinod with them well Finally getting eng bh and tranny in BUT there is NO way the drivers side header will fit between the block and steering shaft also they dump Straight into the tortion bar ???? help i really Dont want to run stock manifolds Unless i have to

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Updated SPITFIRE HEADER INSTALL 63-66 A-body

- Thread starter daves66valiant

- Start date

-

madmax669

Well-Known Member

looks like the left header outlet is dumping out at the torsion bar

seriously. quick cool down temps on valves?. please explain this one.

The theory & anecdotal testimony is that on cold days/nites shutting down

the engine hot w/open headers creates a natural convection draft thru any open

valves.primarily ones on overlap thus subjecting the very hot exh valve to uneven

thermal stress as colder air ends up pulling past. warped valve, crap compression

burned valve after a few more runs. thats it

thanks for the explanation. i was still wondering even though i asked the question in july of 2013. lol #-oThe theory & anecdotal testimony is that on cold days/nites shutting down

the engine hot w/open headers creates a natural convection draft thru any open

valves.primarily ones on overlap thus subjecting the very hot exh valve to uneven

thermal stress as colder air ends up pulling past. warped valve, crap compression

burned valve after a few more runs. thats it

so i guess that if i dont shove steel wool up my exhaust my engine is going to run like **** cause i will warp a valve and have shitty compression and burn a valve on the next run? wow. you learn something new every day. i knew steel wool had more than one use.

BIGFISH

Member

As far as Durango/Dakota manifolds go, I ordered a set of Dorman replacement manifolds from Summit Racing and they do not fit. Passenger side manifold is too thick/wide and hits inner fender as well as the drivers side hanging up on the steering coupler. Also the dump on both sides is at a bad angle. They could be made to fit, but I felt it was more work than it's worth. I'm now in the process of modifying Summit brand Durango/Dakota headers to fit. A bit of work but it is gonna be a better fit and I won't have to use dual exhaust like the TTI setup.

bigjim64

Active Member

wow looks great a lot less hassle than the tti i have in my 64 did you have to do anything with the oil filter?Got the spitfires installed today. The install went very easy compared to the TTI's. Makes me want to go to manual steering on my convertible.

Car: 1966 Plymouth Valiant 360 4 speed

These headers do not require you to remove anything from the car besides the old 273 stock manifolds which are useless for any kind of street car. I had to move my power brake booster and master cylinder out of the way to make room, but that was easy enough. I didn't even have to disconnect the brake lines which was nice. By the way you can use the stock starter as well.

View attachment 1715059259

A little advice DO NOT USE ALLEN HEAD BOLTS. I used ARP header bolts with the hex heads. You WILL need to remove the cylinder head studs. Vice grips worked well. Oh and keep a drain pan handy since the water jackets are behind these studs.

View attachment 1715059260

DRIVER'S SIDE

With the ARP header bolts I had to shave a little off one of the bolts to get clearance. It was the 4th bolt next to #5 spark plug. This may not be necessary with standard style hex head bolts. See pic below

View attachment 1715059261

Now to keep the gasket in place slightly thread in two bolts at #1 and #5. These headers have slotted holes which was very nice. Next, you'll slide the header on while tightening #5 bolt until it just starts to get snug against the header flange. Here is where you will want to start lining up all the other bolts as well. You'll see what I mean once you start installing them. Then just tighten everything down and you're done.

View attachment 1715059262

View attachment 1715059263

PASSENGER SIDE

Unfortunately, a good buddy of mine (ahem Johnny Dart) snapped one of the stud bolts in the passenger side cylinder head. =P~ This was a pain in the *** because I busted an ez-out in the hole I had drilled into the stud. :angry7: Had to bust out the dremel and grind it out so I could then drill out the stud and re-tap the thread. THANKS JOHNNY for that fun filled adventure. LOL.

View attachment 1715059264

The passenger side goes on just as easily. You will need the 90* oil filter adapter unless you are running a remote filter. Once again if using the ARP header bolts, you will need to massage/indent the header tube next to the #2 plug and shave the top of the bolt lightly. Same as the driver's side, to keep the gasket in place thread the bolts next to #2 and #6. Slide everything in place and tighten. DONE.

View attachment 1715059265

Dumps above the torsion bars

View attachment 1715059266

I'll be headed to the muffler shop tomorrow with open headers :cheers: to get new pipes hooked up. I plan to use a drag racing header style slip joint, which I've heard does not leak nearly as much. Hope this helps.

This was so simple, smooth and easy. The fit is great. These headers do not come with the exhaust pipe flanges welded on. Harold leaves this option open to the individual's preference. Harold is great to deal with and he is in production for sure. It took 5 weeks to get mine. Mention this website too :-D

Spitfire Headers

Harold Johnson

(479)650-9989

Dave

10 year old thread but Dave was online here today. May be he still has those headers on.Sure hope mine come through soon. He cashed my check. Can't reach him by phone since. Left a couple of messages. Everything is on hold until I get the headers.

daves66valiant

68 Dart 340/727:66 Signet Vert 340/5spd: 68 D100

Easy install but Sold them long ago. Have a set of Doug’s on that car now. 90* oil filter adapter worked well. I have one of the early-a tti sets on my convertible valiant as well. Pita installing those but they look great.

Easy install but Sold them long ago. Have a set of Doug’s on that car now. 90* oil filter adapter worked well. I have one of the early-a tti sets on my convertible valiant as well. Pita installing those but they look great.

So,is Herold still around?

daves66valiant

68 Dart 340/727:66 Signet Vert 340/5spd: 68 D100

No idea if he’s around. I doubt it honestly.So,is Herold still around?

abodyjoe

Well-Known Member

Haven't heard anything about him in years.

rdunnam

RDunnam

For planning purposes, using Schumacher mounts, or any other brand, to install any small block in place of a six (six K-frame remains) or an eight (into eight K-frame) versus the OEM engine mounts on an eight replacing an eight, for header clearance purposes, does the engine end up being at the same spot from steering shaft and other engine bay components, etc, correct? I read through this old thread and I know there's hundreds of threads out there on headers being installed in early A's, maybe more recent threads for sure (than this Spitfire thread) on TTI's and even other brands installed into the early A's, I'm thinking if different motor mounts (brands) can make a small difference when this guy has to bend the header in this spot or that spot to get his to work when the next guy posting did not, etc. I guess what I'm asking, have people run across motor mount dimensional differences causing headers install differences (clearances)?Haven't heard anything about him in years.

abodyjoe

Well-Known Member

conversion mounts are supposed to put the new motor where it would have come stock.. tti even gives you measurements for the crank centerline sice the tolerances on some of these cars are horrible..

PistolGrip

Well-Known Member

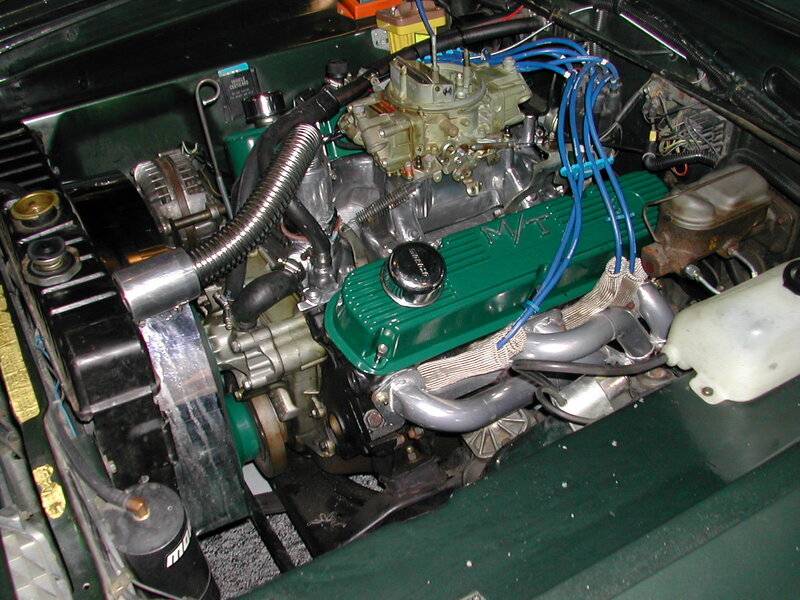

This is a great 'how to' for these headers. I bought mine when Howard was just getting started many years ago & they're still on my Barracuda today. I had mine ceramic coated because I never wanted to mess with them again! So far....so good. One thing I did differently was use a shorty oil filter instead of the 90 degree adapter (I always thought the adapter was just one more thing that could leak). Here's the Spitfires on my '66 Barracuda with a 360 engine.

The engine location question framed in terms of relationship to steering shaft reminded me of what I learned early in my A-Body days about fine tuning the fit. The slotted K-frame pads for the motor mounts allow a significant amount of latitude for adjusting clearances around the engine. My 65 A/Sedan SCCA Barracuda race car (street converted) was a nightmare on the driver's side with 60's vintage Doug Thorley underchassis headers that were assembled as slip-fit upper primary tubes into the bottom tubes from the collector. In those days there were no mini-starters available. The steering column tube had been shortened to end at the cowl and the slip joint above the steering box had been eliminated with a slim spline collar. Even then and with solid motor mounts mimicking the rubber, the engine needed to be carefully adjusted at the K-member slots to gain that 1/8". That lesson helped soon after when I started using 68-70 340 exhaust manifolds. I'm also a veteran of Spitfire header use and they were a great niche solution to the manifold dilemma. Now I'm back to using 340 manifolds and the very high quality TTI's. I've looked at the latest Thorley headers with interest too. Taking advantage of mounting point adjustability is still key.

The engine location question framed in terms of relationship to steering shaft reminded me of what I learned early in my A-Body days about fine tuning the fit. The slotted K-frame pads for the motor mounts allow a significant amount of latitude for adjusting clearances around the engine. My 65 A/Sedan SCCA Barracuda race car (street converted) was a nightmare on the driver's side with 60's vintage Doug Thorley underchassis headers that were assembled as slip-fit upper primary tubes into the bottom tubes from the collector. In those days there were no mini-starters available. The steering column tube had been shortened to end at the cowl and the slip joint above the steering box had been eliminated with a slim spline collar. Even then and with solid motor mounts mimicking the rubber, the engine needed to be carefully adjusted at the K-member slots to gain that 1/8". That lesson helped soon after when I started using 68-70 340 exhaust manifolds. I'm also a veteran of Spitfire header use and they were a great niche solution to the manifold dilemma. Now I'm back to using 340 manifolds and the very high quality TTI's. I've looked at the latest Thorley headers with interest too. Taking advantage of mounting point adjustability is still key.

I should add I don't recommend the elimination of the slip joint in the steering. The use of a little u-joint is questionable also given the flex that occurs between the steering box and the cowl. I was probably lucky to get away with street driving that setup which is a totally different load cycle then short bursts of racing with extensive maintenance between sessions.

pishta

I know I'm right....

In my history of looking at header combos that could fit early A's, the nice cheap stainless Dakota headers were WAY too wide to fit as they really come out the heads and sweep down gracefully, not the violent 90 that the headers need to clear any thing on these. Most LA headers fit the passenger side with ease (check idler arm!) , but the driver 3 and 5 were the PITA. One style takes the 5 and pushes it straight back to the 7 and then down, that's the style you can work with as the #3 just needs to be tucked between the manual steering box and the block. And you could always take the #1 straight down and under the LCA pivot. Sadly, full fenderwells (old Cyclone, Hedman) are the best option but the least attractive to a purist. I dont have any experience with the new mega buck TTI's or other under chassis headers 'cept the infamous small tube Hooker SC 5208 (love 'em or hate 'em: they fit).

Pishta, agree with you that the classic Hookers fit. Of course that's for drag cars or high riding hot rods. As you can see from the road race Valiant pic I use in my profile, the height of a car tuned for corners kills exhaust clearance. The Hooker tube dropping under the steering will pretty much get hammered shut on a street car. The only time I've used fender wells is with big blocks, my last being a 65 Valiant 440. No pretension of cornering there, aggravated by skinny front wheels to clear the headers. The Valiant in my picture had headers that went up and forward on the driver's side, across the front and back to join the passenger side to a tunnel built above the passenger side floor. No exhaust protruded below the pan until dropping to the side exit. That's how you go low.... Not my car so I'm not posting the builder's photos that were shared with me years ago, sorry.

I meant to mention I've seen a B block (383/400) in an early A-Body using factory manifolds, don't know what ones, with successful clearance.Pishta, agree with you that the classic Hookers fit. Of course that's for drag cars or high riding hot rods. As you can see from the road race Valiant pic I use in my profile, the height of a car tuned for corners kills exhaust clearance. The Hooker tube dropping under the steering will pretty much get hammered shut on a street car. The only time I've used fender wells is with big blocks, my last being a 65 Valiant 440. No pretension of cornering there, aggravated by skinny front wheels to clear the headers. The Valiant in my picture had headers that went up and forward on the driver's side, across the front and back to join the passenger side to a tunnel built above the passenger side floor. No exhaust protruded below the pan until dropping to the side exit. That's how you go low.... Not my car so I'm not posting the builder's photos that were shared with me years ago, sorry.

Deeeno

Active Member

Can I just call Harold to get some for my 65 barracuda?Got the spitfires installed today. The install went very easy compared to the TTI's. Makes me want to go to manual steering on my convertible.

Car: 1966 Plymouth Valiant 360 4 speed

These headers do not require you to remove anything from the car besides the old 273 stock manifolds which are useless for any kind of street car. I had to move my power brake booster and master cylinder out of the way to make room, but that was easy enough. I didn't even have to disconnect the brake lines which was nice. By the way you can use the stock starter as well.

View attachment 1715059259

A little advice DO NOT USE ALLEN HEAD BOLTS. I used ARP header bolts with the hex heads. You WILL need to remove the cylinder head studs. Vice grips worked well. Oh and keep a drain pan handy since the water jackets are behind these studs.

View attachment 1715059260

DRIVER'S SIDE

With the ARP header bolts I had to shave a little off one of the bolts to get clearance. It was the 4th bolt next to #5 spark plug. This may not be necessary with standard style hex head bolts. See pic below

View attachment 1715059261

Now to keep the gasket in place slightly thread in two bolts at #1 and #5. These headers have slotted holes which was very nice. Next, you'll slide the header on while tightening #5 bolt until it just starts to get snug against the header flange. Here is where you will want to start lining up all the other bolts as well. You'll see what I mean once you start installing them. Then just tighten everything down and you're done.

View attachment 1715059262

View attachment 1715059263

PASSENGER SIDE

Unfortunately, a good buddy of mine (ahem Johnny Dart) snapped one of the stud bolts in the passenger side cylinder head. =P~ This was a pain in the *** because I busted an ez-out in the hole I had drilled into the stud. :angry7: Had to bust out the dremel and grind it out so I could then drill out the stud and re-tap the thread. THANKS JOHNNY for that fun filled adventure. LOL.

View attachment 1715059264

The passenger side goes on just as easily. You will need the 90* oil filter adapter unless you are running a remote filter. Once again if using the ARP header bolts, you will need to massage/indent the header tube next to the #2 plug and shave the top of the bolt lightly. Same as the driver's side, to keep the gasket in place thread the bolts next to #2 and #6. Slide everything in place and tighten. DONE.

View attachment 1715059265

Dumps above the torsion bars

View attachment 1715059266

I'll be headed to the muffler shop tomorrow with open headers :cheers: to get new pipes hooked up. I plan to use a drag racing header style slip joint, which I've heard does not leak nearly as much. Hope this helps.

This was so simple, smooth and easy. The fit is great. These headers do not come with the exhaust pipe flanges welded on. Harold leaves this option open to the individual's preference. Harold is great to deal with and he is in production for sure. It took 5 weeks to get mine. Mention this website too :-D

Spitfire Headers

Harold Johnson

(479)650-9989

Dave

grimreaper

Cross Member

Harold has mot made them for years

Laysons sells a copy these days.

Laysons sells a copy these days.

moparraceman

Well-Known Member

if the pipe dumps on the torsion bar ,can exhaust be put on these headers in a 63 340 dart ?

Moparmonster

Well-Known Member

$225?!? And I was thinking that the last set I saw at $1,000 was a good price.On an added note. Harold called me to check and see how the headers worked out yesterday. Nice guy. He also added that these headers will fit 67 and up a-bodies with power steering as well.

$225 for a set of a-body headers is a damn good deal to me.

I'll post more pictures of the exhaust hook up with the z-bar and all soon.

Dave

That was 17 years ago and from the original maker of them.$225?!? And I was thinking that the last set I saw at $1,000 was a good price.

-

Similar threads

- Replies

- 0

- Views

- 246

- Locked

- Replies

- 0

- Views

- 345

- Replies

- 1

- Views

- 551

- Replies

- 0

- Views

- 211