Make sure the hub clears the wheel; I'm going to have to radius the nose of the hub a little. For the garage I am using a 7mm spacer to allow the wheel to clear so I can roll the car.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

When does money outweigh sentimental value? 1968 notchback build thread

- Thread starter khuebner250

- Start date

-

khuebner250

Well-Known Member

I forgot to mention that I had the wheel machined about 3/16" in hub depth.Make sure the hub clears the wheel; I'm going to have to radius the nose of the hub a little. For the garage I am using a 7mm spacer to allow the wheel to clear so I can roll the car.

khuebner250

Well-Known Member

Some updates. Here is a picture of the rear window channel. You can see where my paint and body guys decided to weld up all my trim holes, so that was nice of them.

khuebner250

Well-Known Member

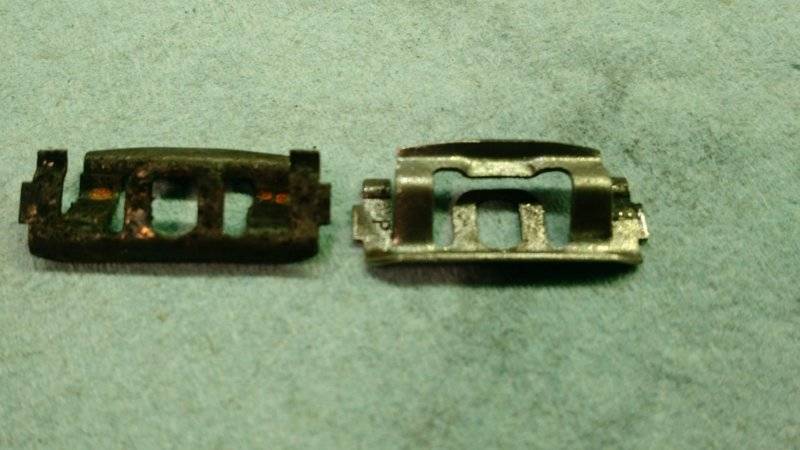

I did get the trim holes drilled and trim clips installed. The new trim clips I bought were wrong for the front. The ones I took off are the thin ones and the new ones are the fat ones. First pic is the front and back of the small clips, I had to clean and coat them. Here you can see clips installed and also see the air dam mock up.

khuebner250

Well-Known Member

Headliner is in and looking good.

khuebner250

Well-Known Member

New beer fridge! And all my glass is cleaned, tinted and wrspped up on top of my messy box. Just need to start polishing SS. But this post is mainly about the new beer fridge, which is awesome!

khuebner250

Well-Known Member

Mods. My kids have officially named my car Avocuda. So maybe it's time to retitle this thread.

Avocuda build thread

Avocuda build thread

moparmat2000

Well-Known Member

Ya gotta have a beer fridge. When we got a new one for the house, i took the old one out to the shop. Comes in handy to have too when you need to stock extra goodies for an upcoming party.New beer fridge! And all my glass is cleaned, tinted and wrspped up on top of my messy box. Just need to start polishing SS. But this post is mainly about the new beer fridge, which is awesome!

View attachment 1715226358

View attachment 1715226359

View attachment 1715226361

moparmat2000

Well-Known Member

Black interior ? Or dark green?

loganscuda

This/These

Is that a Randy’s spoiler on the front

khuebner250

Well-Known Member

Also disassembled the engine that I rebuilt in HS. Looked good inside (low miles) but its going to a 408, so I dropped it off at ridge reamer in Arvada. Waiting to hear from Pete. Having it align honed with studs, bores rehoned, square decked, cam bearings, plugs, etc. I also did the oil mods from guitar Jones. And some side cooling lines into block

khuebner250

Well-Known Member

Dark metallic green.Black interior ? Or dark green?

khuebner250

Well-Known Member

Yep. Fit was ok. I had to do some 'tweeking'. And ran a small foam strip between spoiler and valance. Here it is installed.Is that a Randy’s spoiler on the front

khuebner250

Well-Known Member

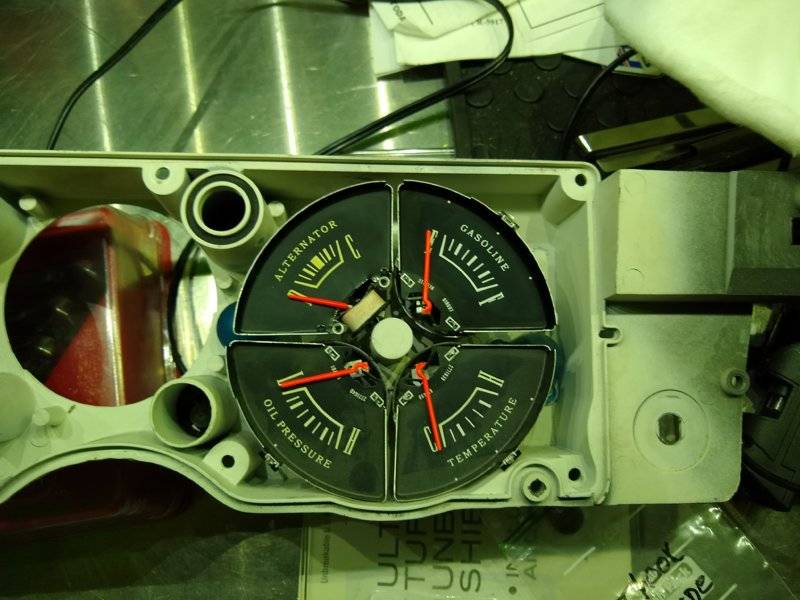

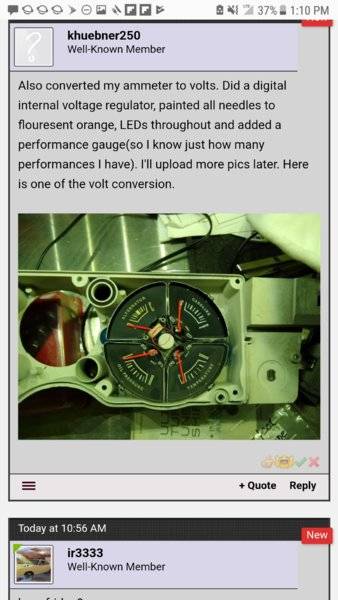

Also converted my ammeter to volts. Did a digital internal voltage regulator, painted all needles to flouresent orange, LEDs throughout and added a performance gauge(so I know just how many performances I have). I'll upload more pics later. Here is one of the volt conversion.

ir3333

Well-Known Member

beer fridge?

the cool cement floor in my shop keeps my beer chilled perfect!

the cool cement floor in my shop keeps my beer chilled perfect!

moparmat2000

Well-Known Member

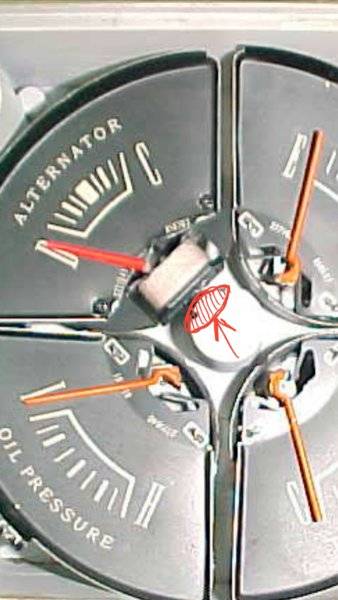

Your gonna have a problem here you either have to grind away part of the gage bucket shown in red to get the volt gage lower pendulum to swing so the needle will move, or cut that part off the gage so it clears. I ground my gage bucket instead. Not sure how much removing the pendulum interferes with the gages calibration.

Last edited:

khuebner250

Well-Known Member

Your gonna have a problem here you either have to grind away part of the gage bucket shown in red to get the volt gage lower pendulum to swing so the needle will move, or cut that part off the gage do it clears. I ground my gage bucket instead. Not sure how much removing the pendulum interferes with the gages calibration.

I did, I just removed it from the side. It sweeps.

moparmat2000

Well-Known Member

You can also hook the gage up to a fully charged battery on your workbench and adjust the potentiometer on the gage to read where you want the needle to read. I chose slightly above half at 13.5 volts with gage positioned as it will sit in the dash because of gravity pulling on the needle. I actually cut my needle off leaving a small stub, and super glued on the original needle from the ammeter so it all matches, then made the pot adjustment.

Also if you use a plastic or rubber insulator for your hot lead, run that straight to the 12v feed at the fuel gage, and run the volt gage ground wire washered up right to the gage housing. That is a ground anyways. In my pic, i eventually eliminated the black ground wire as i grounded the gage to the gage housing. You can see the red wire hooking up at the 12v in at the fuel gage.

The rest of the gages are 6 volt. Using a vibrating points reg in the fuel gage. I removed mine, and built a soild state 5.5v regulator thats externally mounted

Also if you use a plastic or rubber insulator for your hot lead, run that straight to the 12v feed at the fuel gage, and run the volt gage ground wire washered up right to the gage housing. That is a ground anyways. In my pic, i eventually eliminated the black ground wire as i grounded the gage to the gage housing. You can see the red wire hooking up at the 12v in at the fuel gage.

The rest of the gages are 6 volt. Using a vibrating points reg in the fuel gage. I removed mine, and built a soild state 5.5v regulator thats externally mounted

moparmat2000

Well-Known Member

I used led 5630 dimmable flexible peel and stick light strip for my gage backlighting. Its inexpensive and eliminates bright and dark spots. I will post pix if your interested. It works very well. I can sell you a 4 foot strip if interested. I have it in your fav colour. Green.

khuebner250

Well-Known Member

I used led 5630 dimmable flexible peel and stick light strip for my gage backlighting. Its inexpensive and eliminates bright and dark spots. I will post pix if your interested. It works very well. I can sell you a 4 foot strip if interested. I have it in your fav colour. Green.

I have essentially the same set up as you. Solid state ivr, voltmeter, wiring as you stated but I'm running superbrightleds. I do need to calibrate the voltmeter still. I'll post more pics later.

khuebner250

Well-Known Member

Ya gotta have a beer fridge. When we got a new one for the house, i took the old one out to the shop. Comes in handy to have too when you need to stock extra goodies for an upcoming party.

I had a good friend finish his basement and this was his basement fridge. He was just going to get rid of it.

I'm interested in the lighting you are talking about if you could post a photoI used led 5630 dimmable flexible peel and stick light strip for my gage backlighting. Its inexpensive and eliminates bright and dark spots. I will post pix if your interested. It works very well. I can sell you a 4 foot strip if interested. I have it in your fav colour. Green.

moparmat2000

Well-Known Member

That brightness was with a 9v battery. First pic shows how i soldered it to a bulb socket and plugged it it.

Thanks. That does light things up!That brightness was with a 9v battery. First pic shows how i soldered it to a bulb socket and plugged it it.

View attachment 1715226493

View attachment 1715226494

View attachment 1715226496

View attachment 1715226497

moparmat2000

Well-Known Member

Leds are polarity sensitive. Best thing to do is bench test your backlighting with a 9v batt and 2 alligator end test leads. Hook ground to the gage housing and hot to pin on circuit board that feeds the lighting. If it doesnt light, just turn bulb 180° and drop back in the socket, or ditto with leads on the light strip if soldered to a bulb socket.

-

Similar threads

- Replies

- 2

- Views

- 2K

- Replies

- 56

- Views

- 986