Put drain tubes in back corners in case water gets in?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

When does money outweigh sentimental value? 1968 notchback build thread

- Thread starter khuebner250

- Start date

-

moparmat2000

Well-Known Member

I like the battery box idea with all your electronics and the lithium ion battery in it. Do you have detailed pix on how you did that? I am also going to look for some Audi TT 3rd brake lights for both cudas. Excellent idea, I will be copying that.

Zcuda68

Well-Known Member

Great work, looks gorgeous

DionR

Well-Known Member

Any more updates? Love to see some overall pictures sitting in the sun.

khuebner250

Well-Known Member

Any more updates? Love to see some overall pictures sitting in the sun.

Honestly, not so much. In October I blew out my back and pinched two nerves. So Oct to Jan have pretty much been rehab, couple nerve blocks, cortisone injections, MRI's, massage, chiro and PT. Then the Wubanic plague shut things down. A few weeks ago I found someone to hardcoat III my alternator pulley. So I pulled that and sent it. Here's some before and afters.

Last edited:

A few weeks ago I found someone to hardcoat III my alternator pulley.

View attachment 1715542352

Is that a "hard anodized" black coating? I would be interested in doing that with my alternator and crank pulley.

khuebner250

Well-Known Member

Is that a "hard anodized" black coating? I would be interested in doing that with my alternator and crank pulley.

Yes type III hard anodized @ .002 thickness. Same as an AR15 milspec lower. I payed shipping each way and supplied a return label. Cost me $40 plus shipping. He turned is in 2 days. lmk and I'll get you his info.

khuebner250

Well-Known Member

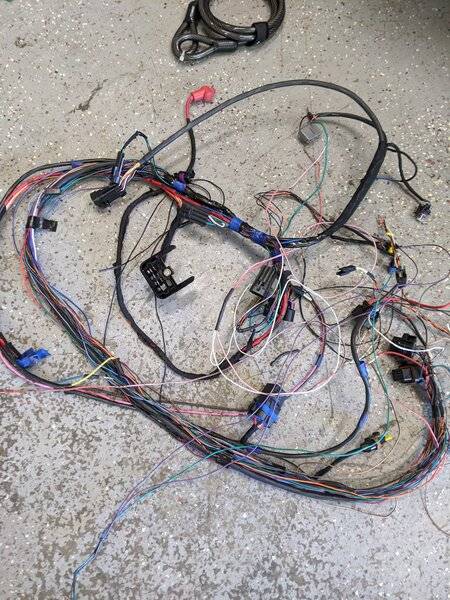

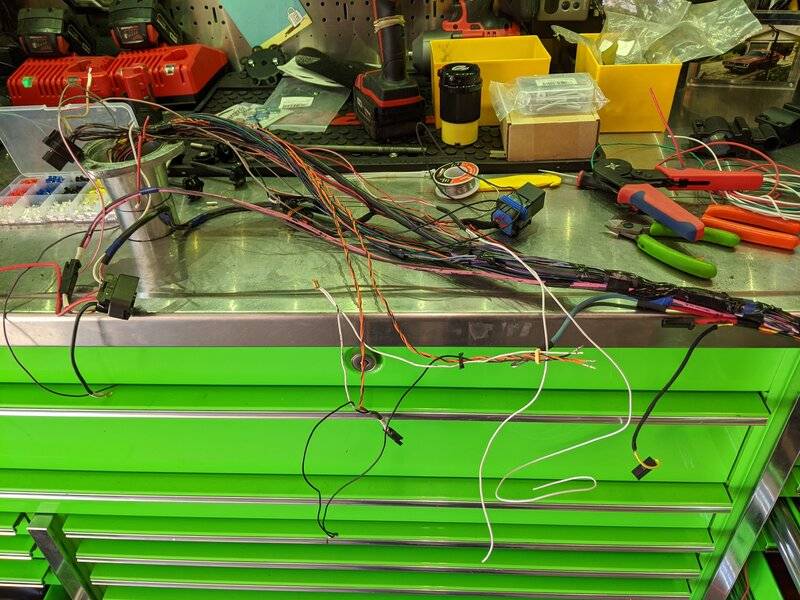

When I sent the pulley off, I figured I'd upgrade my alternator wire from 8G to 6G. And also see if I can find out why my CAN bus 2 is having connectivity issues. So I pulled the engine / EFI harness and got to dismantling. I'm currently waiting for some connector pins and 22G wire. I've got to depin a couple of terminated wires and fix some factory holley splices that I don't care for. So that escalated quickly.

Pulled

Deconstructed

Pulled

Deconstructed

khuebner250

Well-Known Member

I also mounted my halogen fire extinguisher. I called the lithium battery manufacturer to verify there is no actual lithium metal within said battery, which there isn't. So no need for a type D extinguisher, they recommended the halogen.

khuebner250

Well-Known Member

I like the battery box idea with all your electronics and the lithium ion battery in it. Do you have detailed pix on how you did that? I am also going to look for some Audi TT 3rd brake lights for both cudas. Excellent idea, I will be copying that.

So since I pulled the alternator and the engine / EFI harness. I figured what the hell, I may as well upgrade the fan inside the battery box. I'm going from a 22 CFM fan to an 80 CFM fan. I also need to transfer a hole into the battery tray for more air. I ordered some frogzskins hydrophobic mesh. So I'll put a mesh screen on the bottom side of the fan and I'll cut vent holes in the top of the battery box lid to aid in better air circulation. I also ordered some polyethylene 1/8" rod to friction weld the battery box for more strength. So, here are the pics of battery box deconstructed as of today. These pics show SSD relays, grounding bus, battery common stud, CDI ignition, ECU, ABS battery box and fan. Lithium battery is not pictured.

DionR

Well-Known Member

Honestly, not so much. In October I blew out my back and pinched two nerves. So Oct to Jan have pretty much been rehab, couple nerve blocks, cortisone injections, MRI's, massage, chiro and PT. Then the Wubanic plague shut things down. A few weeks ago I found someone to hardcoat III my alternator pulley. So I pulled that and sent it. Here's some before and afters.

View attachment 1715542350

View attachment 1715542351

View attachment 1715542352

Ouch, hate to hear you got hurt. I thought maybe you were just enjoying the car so much you had forgotten about us. Wish that had been the case for you.

khuebner250

Well-Known Member

Here's the battery tray with a 3-in hole cut in it. However after attempting to put my new fan inside the battery box it was 10 mm taller than the old one and wouldn't fit. So I had to mount the fan on the under side of the battery box. So I had to enlarge the whole and turn it into a square for the fan to pass through the tray. I had some leftover raptor liner so I tinted it quick and coated the tray.

khuebner250

Well-Known Member

I mentioned earlier I got some frogzskin mesh. I got turned on to it by a snowmobile guy I work with. It's a super fine mesh screen that has hydrophobic properties. So I thought I would vent the battery box lid. Lmk what you think.

khuebner250

Well-Known Member

I got my terminal pins and 22g wire colors that I was waiting for.

That allowed me to eliminated about 9 wires, 4 unneeded connectors and a bunch of factory splices. it made the harness a tiny bit smaller which I made up for by increasing alternator wire gauge from 8 to 10.

I repinned about 10 wires in the main EFI connectors. I extended CTS, FPS and coolant sender to reroute around the distributor and under the intake.

I then test fit, did a systems check and test fire.

Test fit pic.

That allowed me to eliminated about 9 wires, 4 unneeded connectors and a bunch of factory splices. it made the harness a tiny bit smaller which I made up for by increasing alternator wire gauge from 8 to 10.

I repinned about 10 wires in the main EFI connectors. I extended CTS, FPS and coolant sender to reroute around the distributor and under the intake.

I then test fit, did a systems check and test fire.

Test fit pic.

Last edited:

khuebner250

Well-Known Member

Only thing left to do was figure out my CANbus issues. I retraced and inspected all the holley CANbus wiring. I could not find issue in the wiring itself. After lots of tracing and continuity tests I think the fault was in the Holley CANbus to laptop connector. They had D+ and D- pinned to the power and ground terminals inside the USB connector.

So I did the only rational thing, and ripped out all the factory CANbus wiring. I then re-terminated, pinned and soldered using USB cables in Lieu of the holley stuff.

Figured I might as well put in a USB bulkhead in the firewall too. So then cut a hole in the firewall, made it square and put in a two port bulkhead.

So I did the only rational thing, and ripped out all the factory CANbus wiring. I then re-terminated, pinned and soldered using USB cables in Lieu of the holley stuff.

Figured I might as well put in a USB bulkhead in the firewall too. So then cut a hole in the firewall, made it square and put in a two port bulkhead.

khuebner250

Well-Known Member

I rewrapped the harness and got everything reinstalled. Engine compartment is done sans air box, I'll get to that later, I did a thing.

Car moved under it's own power from the back garage bay to the front.

Car moved under it's own power from the back garage bay to the front.

440jimr

Well-Known Member

Engine compartment is super clean. Your electrical skills are top notch!

khuebner250

Well-Known Member

Put drain tubes in back corners in case water gets in?

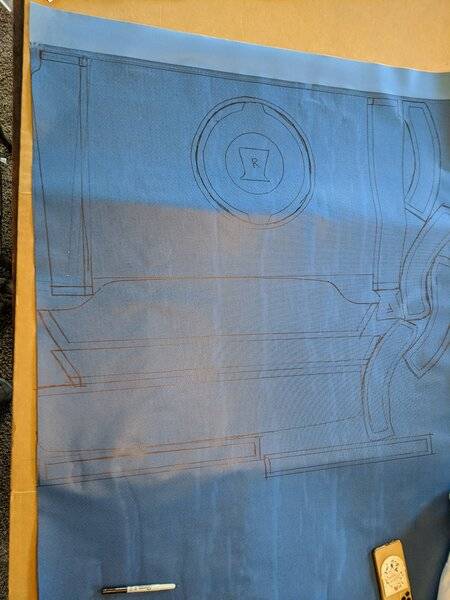

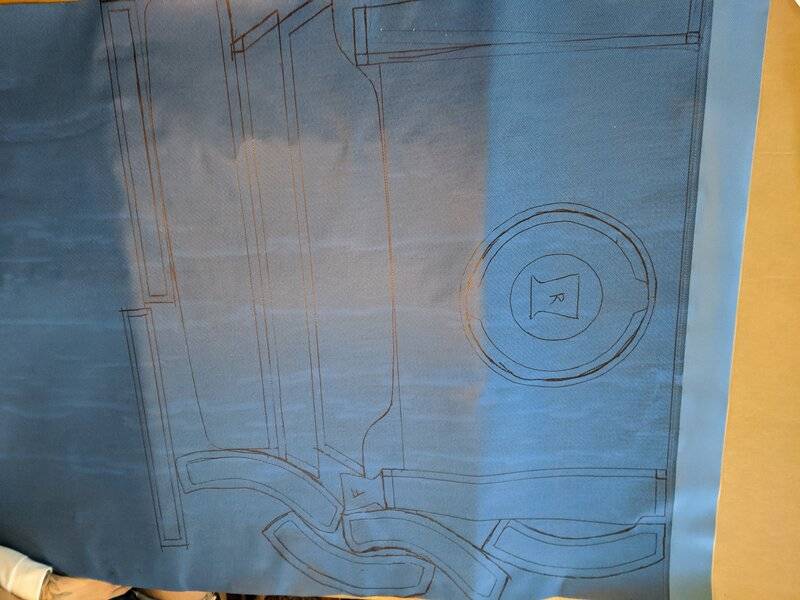

So I said i'd update this thread regarding my air box. In a previous post somewhere I showed an aluminum air box I had made that form fitted to the hood. Well before I could take the engine / EFI harness and alternator wire out I had to remove that air box, and for some reason, I got a wild hair up my ***. Made a couple phone and email exchanges to a company in the UK. Spent some money with them and literally hoped for the best.

Here's disassembly of my air box. First stripped it bare. Then pulled all the rivets.

khuebner250

Well-Known Member

Next I had to get rid of some gouges and surface scratches so that was 2 days of sanding. I then reassembled with aluminum screws. Sanded them flat and upped my sanding from 320-400-600-800.

khuebner250

Well-Known Member

Then the next step after sanding was... more sanding. This time went from dark gray to light gray to white scotch bright pads. Essentially 600 to 800 to 1,000. And then when all the stupid sanding was done. I decided I needed to add some angular reinforcements and rear drain tubes. So then I sanded again. Finish that and began polishing.

khuebner250

Well-Known Member

Then the thing I ordered from the UK showed up. So that means it was arts and crafts time.

I took my polished air box and transferred dims to poster board. And then transferred my poster board cutouts to the UK stuff.

I took my polished air box and transferred dims to poster board. And then transferred my poster board cutouts to the UK stuff.

khuebner250

Well-Known Member

I then went back to polishing. when I was done I added a little bit of flash breaker tape

khuebner250

Well-Known Member

I then cut out all my templates carefully placed them all over my air box stuck them in something that resembled a trash bag, pulled a vacuum on it and stuck it in an oven for 7 hours.

khuebner250

Well-Known Member

This was a bit of a gamble. I wasn't using a conventional mold I was using dissimilar metals in a mold and flashbreaker tape. I figured all those things stacked against me was going to turn this into a disaster. So after it came out of the oven it took me about 20 minutes to break my new mold (made out of my old air box) apart from my new air box. And this is what came out.

khuebner250

Well-Known Member

Looks a bit rough? And it was. A couple pock marks and pinholes in the resin. So I figured since I'd just spent days upon days sanding I'd do more of that. so I did the same thing, started a bit rough, then worked my way up 400, 600, 800 and then white scotch bright. So here it is sanded out.

Last edited:

-

Similar threads

- Replies

- 2

- Views

- 2K

- Replies

- 56

- Views

- 986