You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

WOW! 4.25" Stroke Small Block Cranks now availavbe from BPE!

- Thread starter DJVCUDA

- Start date

-

moper

Well-Known Member

Can't see the pics from this PC. How's it measure out?

BPE

Well-Known Member

I have a couple sets of pistons for the 4.125" cranks that are already spoken for. I will let everyone know when I get the final pricing nailed down. I'm trying to get a deal together and keep pricing down for all of us. I feel like I'm going in three different directions at once right now, but I'm tryin' so if you could bear with me, it will be worth the wait.

Thanks Again for all the interest,

Rod

Thanks Again for all the interest,

Rod

HemiMark

Well-Known Member

I have a couple sets of pistons for the 4.125" cranks that are already spoken for. I will let everyone know when I get the final pricing nailed down. I'm trying to get a deal together and keep pricing down for all of us. I feel like I'm going in three different directions at once right now, but I'm tryin' so if you could bear with me, it will be worth the wait.

Thanks Again for all the interest,

Rod

keep me posted!

mshred

The Green Manalishi

- Joined

- May 2, 2008

- Messages

- 3,310

- Reaction score

- 177

Rod is a class act for sure! I have spoke with him now a couple of times and wouldn't hesitate to use his stuff (in fact I am going to be more than likely). One thing i forgot to ask is if these are drilled for a pilot bearing/bushing.

Dave, let us know what it journals spec out at. It really wouldnt be a bad thing if it needed work since its typical of the budget cranks, but if its perfect Rod is getting a call from me ASAP to get my hands on one (a 4.125" one that is)...sure as hell looks purdy though, and Rod's piston quotes he gave me are VERY reasonable

I am excited! lol

Dave, let us know what it journals spec out at. It really wouldnt be a bad thing if it needed work since its typical of the budget cranks, but if its perfect Rod is getting a call from me ASAP to get my hands on one (a 4.125" one that is)...sure as hell looks purdy though, and Rod's piston quotes he gave me are VERY reasonable

I am excited! lol

Badart

Senior Member

Finally more aftermarket mopar parts. :cheers:

moper

Well-Known Member

Rod - Who's making the pistons? Are they offset pin? I'm assuming a quench dish option? How many ccs are they? What ring package.

The pic looks ok but I'm curious how they measure out.

The pic looks ok but I'm curious how they measure out.

jeremiah2146fa

Well-Known Member

Any updates on this yet?

WOW! Indeed. Please do stop back in from time to time and keep us guys in the loop about this!

jeremiah2146fa

Well-Known Member

The timing of this is perfect for me (as long as the updates keep comming). I'm in the middle of the planning phase for my build now. I'm gonna be leaving for Afghanastan next month to work as a civilian contractor for a year (BIG MONEY). As soon as I leave, a buddy of mine will pick up my car and bring it back to his shop where he'll spend the year building, cutting, and painting. (He wanted another project, and I want my car tricked out by the time I get home, so it's a win/win situation for both of us.)

Step one is gonna be yarding out the old 360, and takin the block to the machine shop. I'd REALLY like to have a plan by the time it gets there. I thought I did, 4" crank,eddy heads,ect... but now I find myself day dreaming about 440CI small blocks with W2 heads.

Step one is gonna be yarding out the old 360, and takin the block to the machine shop. I'd REALLY like to have a plan by the time it gets there. I thought I did, 4" crank,eddy heads,ect... but now I find myself day dreaming about 440CI small blocks with W2 heads.

mshred

The Green Manalishi

- Joined

- May 2, 2008

- Messages

- 3,310

- Reaction score

- 177

Got my rotating assembly together -

BPE's pistons with a -17cc dish for a 10.25:1 with a .039 fel pro 1008 head gasket.

I never made it to the machine shop to measure the crank out - when I do I will update the post.

what chamber size on the heads? those pistons look really nice! whats the compression height on yours?

The chamber on an Eddy head is 63cc'swhat chamber size on the heads? those pistons look really nice! whats the compression height on yours?

they are 1.32 or 1.33 CH - I dont have the papers in front of me.

You'd have to call Rod on that - I got the pistons, pins, and rings included for alot less then anyone else for just pistons and pins.whats the $$$ on these?

What's the bob weight ???

595 grams for the rods

468 grams for the pistons so far - I have not weighed the rings, pins, etc, but I al looking at a +/- 1700 gram bobweight.

65Val

Average Length Member

Subscribed

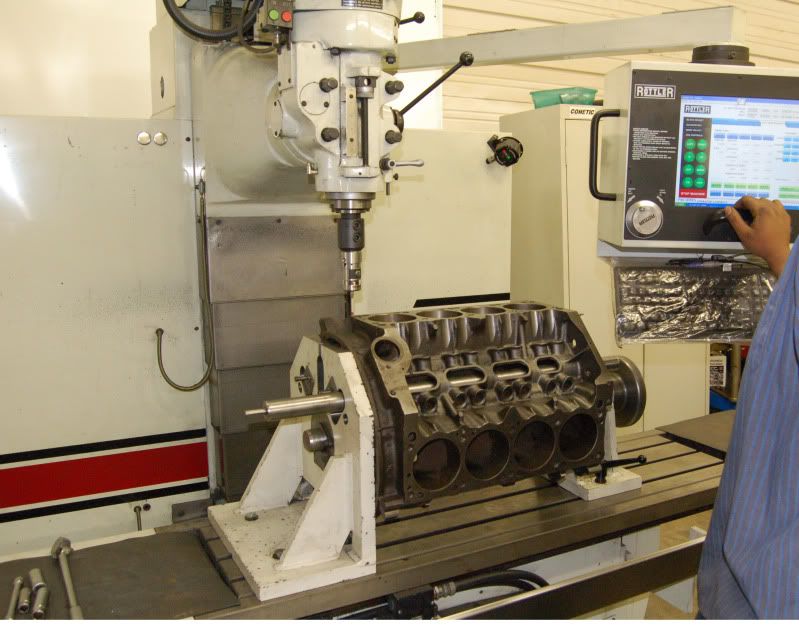

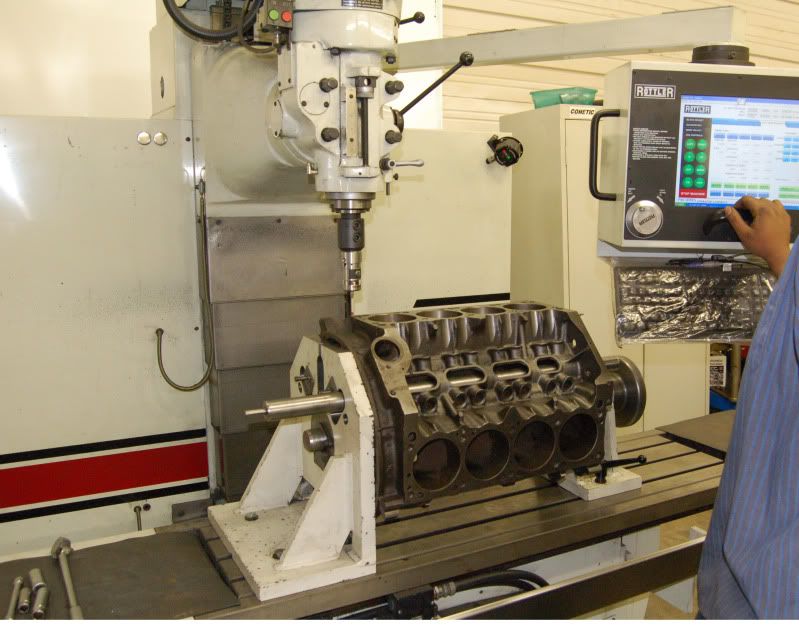

OK - Whew - what a long day yesterday was - went to the machine shop for about 4 hours yesterday and got the following information:

Block - Sonic'd out good and magged good - .400+ on the thrust sides ( X block) and mostly 200 - 300 on the other sides of the cylinders.

after the steel shot machine the thing looks good as new -

Before :

After:

On to the Crank -

We checked a number of things to determine the overall quality and condition of the crank. - all measurements were taken at 62 degrees F

1 - straightness - .001

2 - OD of the Mains - 2.4998

3 - OD of the rod journals - 1.9995

4 - Taper of rods and mains - ( worst one ) .0002

5 - Out of round - NA

6 - OD of the snout ( to fit balancer later ) 1.532

7 - Stroke - we came up with 4.133" for all throws except one - that was the 3,4 journal and it was 4.134"

The stroke was longer then anticipated, and adds 2 cubic inches to the build, but they are all consistent with one being one thou longer.

We can play with deck heights to get thins to work out fine, so it's not an issue and the other measurements were impressive to say the least. I dont know if the colder temps ( 62 ) had anything to do with the measurements since i think the standard is in the 70's.

Just another thought when i got home last night I went to callies site and looked at the $1100 dragonslayer crank specs and what they guarantee their cranks to spec out at - here is the quote -

Last thing we checked for was the oiling holes were indeed drilled all the way - and they were!

Didnt want to leave any stone unturned with a new part and have an issue later.

BIG THANKS to Fonse Performance - they took good care of me yesterday!

Block - Sonic'd out good and magged good - .400+ on the thrust sides ( X block) and mostly 200 - 300 on the other sides of the cylinders.

after the steel shot machine the thing looks good as new -

Before :

After:

On to the Crank -

We checked a number of things to determine the overall quality and condition of the crank. - all measurements were taken at 62 degrees F

1 - straightness - .001

2 - OD of the Mains - 2.4998

3 - OD of the rod journals - 1.9995

4 - Taper of rods and mains - ( worst one ) .0002

5 - Out of round - NA

6 - OD of the snout ( to fit balancer later ) 1.532

7 - Stroke - we came up with 4.133" for all throws except one - that was the 3,4 journal and it was 4.134"

The stroke was longer then anticipated, and adds 2 cubic inches to the build, but they are all consistent with one being one thou longer.

We can play with deck heights to get thins to work out fine, so it's not an issue and the other measurements were impressive to say the least. I dont know if the colder temps ( 62 ) had anything to do with the measurements since i think the standard is in the 70's.

Just another thought when i got home last night I went to callies site and looked at the $1100 dragonslayer crank specs and what they guarantee their cranks to spec out at - here is the quote -

So for hlaf the price I got a crank within the spec of the Callies Dragonslayer - not bad in my opinion!These shafts are machined to the tolerances demanded by today’s high performance engine builder. Roundness and taper are held to less than .0003 on all rod and main journal diameters. Our final polishing procedures produce excellent load carrying surfaces that ensure extended bearing life and trouble free operation.

Last thing we checked for was the oiling holes were indeed drilled all the way - and they were!

Didnt want to leave any stone unturned with a new part and have an issue later.

BIG THANKS to Fonse Performance - they took good care of me yesterday!

mshred

The Green Manalishi

- Joined

- May 2, 2008

- Messages

- 3,310

- Reaction score

- 177

NICE! This is really good to see and hear! I talked with another member about his and he said it checked out fine also!

I will definitely be going with one of these cranks when i start to collect parts for the stroker that is now on the backburner...Rod definitely wasn't fronting when he told me the quality of these peices! Big Kudos out to him!

Keep us posted on your build man! this is gettin interesting now!

I will definitely be going with one of these cranks when i start to collect parts for the stroker that is now on the backburner...Rod definitely wasn't fronting when he told me the quality of these peices! Big Kudos out to him!

Keep us posted on your build man! this is gettin interesting now!

moper

Well-Known Member

That's excellent. Even tho it's a little cold, so long as the crank and mics are the same temp, and it's not too far off the 70° mark, you're fine. Definately a good value.

Somehow this turned into my engine build thread - so here is the update...

well just a quick update- the deck was a mess when we put it on the ROTTLER CNC machine - 12 thousands off on the drivers side and 10 thousands off on the passenger side.

While the deck was flat - and this block was machined at a very reputable shop in the 80's the machinery of today has brought inconsistencies like this to the forefront of modern engine building.

so I had a flat, crooked deck on this sucker. But it will clean up within spec for the rotating assembly.

Speaking about the rotating assembly - It measured out to 1794.6 grams for the bobweight - nice and light!

Weights were consistent for everything :

Rods: +/- 2 grams - 599-601

pistons - +/- 1 gram - 471-472

Just out of curiosity - does anyone know the stock 340 rotating assembly bobweight?

The TCI Rattler had to be fitted to the crank which was 1.532" and the balancer was 2 1/2 thousands smaller - It was honed to fit with a 1 1/2 thou press fit.

so we're gettin there - slowly but surely.

well just a quick update- the deck was a mess when we put it on the ROTTLER CNC machine - 12 thousands off on the drivers side and 10 thousands off on the passenger side.

While the deck was flat - and this block was machined at a very reputable shop in the 80's the machinery of today has brought inconsistencies like this to the forefront of modern engine building.

so I had a flat, crooked deck on this sucker. But it will clean up within spec for the rotating assembly.

Speaking about the rotating assembly - It measured out to 1794.6 grams for the bobweight - nice and light!

Weights were consistent for everything :

Rods: +/- 2 grams - 599-601

pistons - +/- 1 gram - 471-472

Just out of curiosity - does anyone know the stock 340 rotating assembly bobweight?

The TCI Rattler had to be fitted to the crank which was 1.532" and the balancer was 2 1/2 thousands smaller - It was honed to fit with a 1 1/2 thou press fit.

so we're gettin there - slowly but surely.

1970Duster

Well-Known Member

- Joined

- May 30, 2010

- Messages

- 6,644

- Reaction score

- 220

Pretty sure you would have two different weight (not much though) for the 73 version and the 72 and up

I can tell you that my Forged crank, forged rods, and forged aluminum pistion weight a lot less then stock (which = faster revving :twisted

I can tell you that my Forged crank, forged rods, and forged aluminum pistion weight a lot less then stock (which = faster revving :twisted

340sFastback

Well-Known Member

That is gonna be a nice engine!

moper

Well-Known Member

"While the deck was flat - and this block was machined at a very reputable shop in the 80's the machinery of today has brought inconsistencies like this to the forefront of modern engine building."

Thank you for pointing that out. (not being sarcastic)

Thank you for pointing that out. (not being sarcastic)

"While the deck was flat - and this block was machined at a very reputable shop in the 80's the machinery of today has brought inconsistencies like this to the forefront of modern engine building."

heck, i was at a reputable shop last year while they were decking a block - all they did was follow the existing deck surface and "cleaned 'er up"......after my brother put the block in a Rottler, neither decks weren't parallel to crank, along with different deck heights! the mentality of some machinists just makes me shake my head.......

-

Similar threads

- Replies

- 2

- Views

- 152

- Locked

- Replies

- 3

- Views

- 2K

- Replies

- 3

- Views

- 726

- Replies

- 20

- Views

- 2K

- Replies

- 16

- Views

- 3K