You could have the cam adjusted. It should not cost much to adjust. I had Comp adjust my XE285HL down to a 108. My converter is a 3500 & the automatic 904 is now a manual shifting trans. The lower (numerical) number adds torque. If you had issues with a cam on a 108, with an automatic trans, I’m not sure what the possible problem would be. I can say the rough idle is a real PIA with a manual trans.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

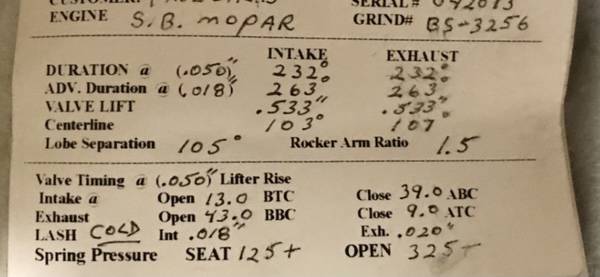

Mopar Performance Purple Mechanical Camshaft - P4120653AE Cam Card

- Thread starter 512Stroker

- Start date

-

512Stroker

We are all here because we are not all there.

I like the idea of a shorter duration on a 110 centerline to gain a higher manifold vacuum which will play well for a street tune with a vacuum advance and a nice idle. Along with a loose converter down low it should have good street driving manners.You could have the cam adjusted. It should not cost much to adjust. I had Comp adjust my XE285HL down to a 108. My converter is a 3500 & the automatic 904 is now a manual shifting trans. The lower (numerical) number adds torque. If you had issues with a cam on a 108, with an automatic trans, I’m not sure what the possible problem would be. I can say the rough idle is a real PIA with a manual trans.

Next step will be to contact Racer Brown and see what can be done. I wonder what lead times are?

Yes Sir - he will absolutely take good care of u and build it around your hardware.I like the idea of a shorter duration on a 110 centerline to gain a higher manifold vacuum which will play well for a street tune with a vacuum advance and a nice idle. Along with a loose converter down low it should have good street driving manners.

Next step will be to contact Racer Brown and see what can be done. I wonder what lead times are?

I like the idea of a shorter duration on a 110 centerline to gain a higher manifold vacuum which will play well for a street tune with a vacuum advance and a nice idle. Along with a loose converter down low it should have good street driving manners.

Next step will be to contact Racer Brown and see what can be done. I wonder what lead times are?

Sorry couldn't rotate photo

This is a Racer Brown solid flat tappet purchased from a member ( new with lifters , it will be for a future project ) .

View attachment 1715772498

Oh I like that one, very nice!

For MY heads, I’d add 1.6 rockers. IIRC, 512 has the Comp 1.5 rockers already. I wouldn’t bother purchasing new rockers ether.

For MY heads, I’d add 1.6 rockers. IIRC, 512 has the Comp 1.5 rockers already. I wouldn’t bother purchasing new rockers ether.

Thank you - SIROh I like that one, very nice!

For MY heads, I’d add 1.6 rockers. IIRC, 512 has the Comp 1.5 rockers already. I wouldn’t bother purchasing new rockers ether.

View attachment 1715772525

512Stroker

We are all here because we are not all there.

Is there a way to calculate cranking cylinder pressure for this cam?Oh I like that one, very nice!

For MY heads, I’d add 1.6 rockers. IIRC, 512 has the Comp 1.5 rockers already. I wouldn’t bother purchasing new rockers ether.

View attachment 1715772525

I noticed that the intake opens @ 13* BDTC is that at .050 ?

Looking at the cam data for a MP .528 cam the intake opens @ 32* BTDC

That's a big difference in the it's ability to build cylinder pressure.

To my understanding the earlier you open the intake the more pressure the cylinder will build.

I have a cam now that has a 9* BTDC intake opening and it low on cranking pressure and a dog out of the hole.

Not trying to be critical, just trying to understand.

I get ya there. You know who is good at this?Is there a way to calculate cranking cylinder pressure for this cam?

I noticed that the intake opens @ 13* BDTC is that at .050 ?

Looking at the cam data for a MP .528 cam the intake opens @ 32* BTDC

That's a big difference in the it's ability to build cylinder pressure.

To my understanding the earlier you open the intake the more pressure the cylinder will build.

I have a cam now that has a 9* BTDC intake opening and it low on cranking pressure and a dog out of the hole.

Not trying to be critical, just trying to understand.

The calculator master @AJ/FormS can calc this one up for you right quick.

512Stroker

We are all here because we are not all there.

For sure I would value his input. Maybe he will chime in.I get ya there. You know who is good at this?

The calculator master @AJ/FormS can calc this one up for you right quick.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,608

- Reaction score

- 13,849

You said;Is there a way to calculate cranking cylinder pressure for this cam?

I noticed that the intake opens @ 13* BDTC is that at .050 ?

Looking at the cam data for a MP .528 cam the intake opens @ 32* BTDC

That's a big difference in the it's ability to build cylinder pressure.

To my understanding the earlier you open the intake the more pressure the cylinder will build.

I have a cam now that has a 9* BTDC intake opening and it low on cranking pressure and a dog out of the hole.

Not trying to be critical, just trying to understand.

To my understanding the earlier you open the intake the more pressure the cylinder will build.

Almost right; but at cranking speed, the engine cannot begin to build cylinder pressure until the intake valve is closed and Not leaking. Since bigger cams close the intake later, the pressure goes down, and you feel that pressure loss as; from lazyness to downright dogginess.

To understand this, you have to know the sequence of valve events.

Beginning from TDC compression; both valves are closed. The piston has come up and compressed the mixture, and it's ready to perform it's work. In an idling engine, the fire was lit around 14 to 20* Before TDC, to make peak pressure at near 28* After TDC. The pressure turns the crank, and by about 90 to 110 degrees After TDC, the pressure transfer is finished, and so, the exhaust valve begins to open. This lets the exhaust out, and this will continue as the piston continues back to TDC, but this time NOT on compression stroke.

Just before the piston reaches TDC, the INTAKE valve will begin to open, while the EXHAUST valve is almost closed. This period of time is called overlap

A little AFTER TDC, the exhaust closes, and the piston is moving down, making room for the incoming air. Thus the INTAKE valve continues to open, then begins to close, BUT, it will not fully close until the piston is stopped , and again rising. It may not be fully closed, with a big cam, until the piston is 1/3 or more of the way up to TDC-compression.

I hope that is understandable.

Now, the reason for the late closing intake, is that as the rpm rises, the incoming air has inertia, and the longer that you keep that intake open, the more air will be able to enter the engine. And that is how you make a low-rpm engine work at a higher rpm. And the faster you can spin it without choking the engine, the more power it will make.

But;

this monkey business wreaks havoc at low rpm. At this time, as the piston is rising with the intake valve still open, it pushes some of that just inducted mixture back out the chamber and into the plenum. Of course, that means less air was trapped in the cylinder, so the pressure is down. And pressure is power, so the less pressure you have, the less power you have.

Say you have a 400 cube V8 engine, that's 50 cubes per cylinder. Now suppose it has a small cam, and at stall speed at some small throttle-opening, each cylinder is able to inhale 20 cubic inches. That would be an efficiency of 20/50=40%.

Now suppose you put a big cam in there with a later-closing intake, that at the very same throttle-opening, 1/4 of the just inducted air was forced back into the intake. Now your efficiency is down to (3/4 of 20) /50=30%..

So you would feel that as a 40% less 30% divided by 40%= a 25% torque loss. So to overcome that you would have to open the throttle more, to make up the difference. And you call it sucked out.

But as the rpm increases, there is less and less time for this turn-around to happen, and eventually your engine could get to 90 or 100 or sometimes even more than 100% efficient.

There are only four ways to stop this from happening;

1) is more Static Compression Ratio, to compress that less trapped air, to a higher level, or

2) to close the intake valve sooner, or

3) to start with a bigger engine

4) to install reed valves in the runners, lol.

As to #1, you have to keep your Dynamic Cylinder Pressure within the limit of your chosen gas to resist detonation. So you cannot arbitrarily increase the pressure to the moon!

As to #2, if you want to keep the high-rpm power, you will have to keep the .050 valve events. So there are limits as to what you can do.

As to #3, well, that's why strokers have become so popular

As to #4, that's a joke,lol. This is how some two-stroke engines make power.

OK, now to answer your question;

Is there a way to calculate cranking cylinder pressure for this cam?

Answer; not for the Wallace calculator;

To calculate the pressure, you need the advertised cam specs like;

284/284/112 +4

But the Wallace does not work with mechanical cams, because there is no way to know the actual events because there is no zero-lash spec.

Therefore, the simplest thing to do, is a cranking compression test. From those numbers, the truth will be revealed. Just be sure that your valves are correctly lashed.

The pressure to run is very subjective. Some guys are happy at 155 with a big iron-headed engine. And some like me, really appreciate 180psi with alloy heads on a 360. If I had a smaller engine, I would push towards 200psi, again with alloys..

But be advised, once the engine is built, cranking pressure is almost totally dependent on the Intake closing angle, AND the elevation at which the engine is being cranked at.

As to the first, you can change that by increasing the lash.

As to the second;Wiki says you are up at about 850 ft, so that's not so bad, with a big engine.

Edited after the fact so refresh your screen.

Last edited:

512Stroker

We are all here because we are not all there.

Great info here, anyone who is purchasing a cam should read this first.You said;

To my understanding the earlier you open the intake the more pressure the cylinder will build.

Almost right; but at cranking speed, the engine cannot begin to build cylinder pressure until the intake valve is closed and Not leaking. Since bigger cams close the intake later, the pressure goes down, and you feel that pressure loss as; from lazyness to downright dogginess.

To understand this, you have to know the sequence of valve events.

Beginning from TDC compression; both valves are closed. The piston has come up and compressed the mixture, and it's ready to perform it's work. In an idling engine, the fire was lit around 14 to 20* Before TDC, to make peak pressure at near 28* After TDC. The pressure turns the crank, and by about 90 to 110 degrees After TDC, the pressure transfer is finished, and so, the exhaust valve begins to open. This lets the exhaust out, and this will continue as the piston continues back to TDC, but this time NOT on compression stroke.

Just before the piston reaches TDC, the INTAKE valve will begin to open, while the EXHAUST valve is almost closed. This period of time is called overlap

A little AFTER TDC, the exhaust closes, and the piston is moving down, making room for the incoming air. Thus the INTAKE valve continues to open, then begins to close, BUT, it will not fully close until the piston is stopped , and again rising. It may not be fully closed, with a big cam, until the piston is 1/3 or more of the way up to TDC-compression.

I hope that is understandable.

Now, the reason for the late closing intake, is that as the rpm rises, the incoming air has inertia, and the longer that you keep that intake open, the more air will be able to enter the engine. And that is how you make a low-rpm engine work at a higher rpm. And the faster you can spin it without choking the engine, the more power it will make.

But;

this monkey business wreaks havoc at low rpm. At this time, as the piston is rising with the intake valve still open, it pushes some of that just inducted mixture back out the chamber and into the plenum. Of course, that means less air was trapped in the cylinder, so the pressure is down. And pressure is power, so the less pressure you have, the less power you have.

Say you have a 400 cube V8 engine, that's 50 cubes per cylinder. Now suppose it has a small cam, and at stall speed at some small throttle-opening, each cylinder is able to inhale 20 cubic inches. That would be an efficiency of 20/50=40%.

Now suppose you put a big cam in there with a later-closing intake, that at the very same throttle-opening, 1/4 of the just inducted air was forced back into the intake. Now your efficiency is down to (3/4 of 20) /50=30%..

So you would feel that as a 40% less 30% divided by 40%= a 25% torque loss. So to overcome that you would have to open the throttle more, to make up the difference. And you call it sucked out.

But as the rpm increases, there is less and less time for this turn-around to happen, and eventually your engine could get to 90 or 100 or sometimes even more than 100% efficient.

There are only four ways to stop this from happening;

1) is more Static Compression Ratio, to compress that less trapped air, to a higher level, or

2) to close the intake valve sooner, or

3) to start with a bigger engine

4) to install reed valves in the runners, lol.

As to #1, you have to keep your Dynamic Cylinder Pressure within the limit of your chosen gas to resist detonation. So you cannot arbitrarily increase the pressure to the moon!

As to #2, if you want to keep the high-rpm power, you will have to keep the .050 valve events. So there are limits as to what you can do.

As to #3, well, that's why strokers have become so popular

As to #4, that's a joke,lol. This is how some two-stroke engines make power.

OK, now to answer your question;

Is there a way to calculate cranking cylinder pressure for this cam?

Answer; not for the Wallace calculator;

To calculate the pressure, you need the advertised cam specs like;

284/284/112 +4

But the Wallace does not work with mechanical cams, because there is no way to know the actual events because there is no zero-lash spec.

Therefore, the simplest thing to do, is a cranking compression test. From those numbers, the truth will be revealed. Just be sure that your valves are correctly lashed.

The pressure to run is very subjective. Some guys are happy at 155 with a big iron-headed engine. And some like me, really appreciate 180psi with alloy heads on a 360. If I had a smaller engine, I would push towards 200psi, again with alloys..

But be advised, once the engine is built, cranking pressure is almost totally dependent on the Intake closing angle, AND the elevation at which the engine is being cranked at.

As to the first, you can change that by increasing the lash.

As to the second;Wiki says you are up at about 850 ft, so that's not so bad, with a big engine.

Edited after the fact so refresh your screen.

My plan at this point for my street driven 340 LA 10.5:1 static running on 91 pump gas is to CNC port (280 cfm @ .650) my existing iron X heads port match an Edelbrock Performer intake (hood clearance issues) and then have a custom flat tappet mechanical cam ground that will take advantage of the heads while maintaining good driving habit's and tune ability.

Using the MP .528 cam as a close model for valve event timing.

I was thinking of a cranking cylinder pressure of 175-180 psi ?

3100 lb A Body, 727 auto 3000 stall 3:55 gears

AJ your thoughts please.

I’d go with the cam AJ runs. 10.5-1 is a bit high for 91. Not that I’d be worried now…. Though I’d watch the cylinder pressure.

512Stroker

We are all here because we are not all there.

OK I missed that.I’d go with the cam AJ runs. 10.5-1 is a bit high for 91. Not that I’d be worried now…. Though I’d watch the cylinder pressure.

What cam does @AJ/FormS run?

91 octane is all we can get around here with no ethanol in it.

Last edited:

Ugh! Memory says something like a 226@050….

I might be mistaken. But I think that’s it.

I might be mistaken. But I think that’s it.

Go on ebay hit

Mopar Performance

I seen alot of camshafts

For ( LA & B / RB )

Mopar Purple units some with lifters also

Mopar Performance

I seen alot of camshafts

For ( LA & B / RB )

Mopar Purple units some with lifters also

512Stroker

We are all here because we are not all there.

Looking thru some old notes on cams, I see where it is not recommended to exceed 165 psi cranking pressure on pump fuel.I’d go with the cam AJ runs. 10.5-1 is a bit high for 91. Not that I’d be worried now…. Though I’d watch the cylinder pressure.

Looks like my parameters just shifted.

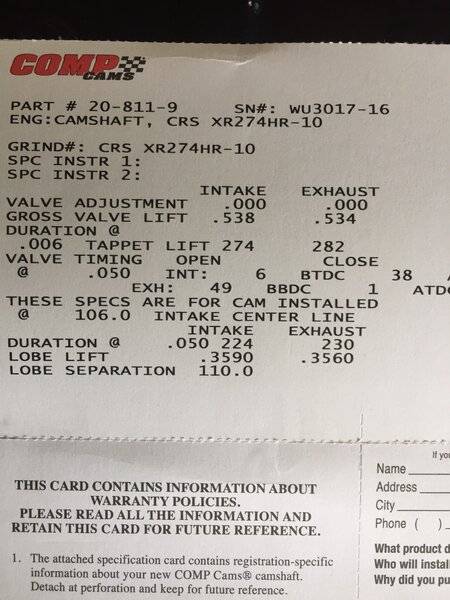

This cam below (& 1.6 rockers) running in a .030 - 360 w/Zero deck Hyperutecic Fed-Mougal slugs, TF heads, .028 Cometic head gaskets on 93 octane.

512Stroker

We are all here because we are not all there.

That is the exact hyd roller cam that I have in the engine now.This cam below (& 1.6 rockers) running in a .030 - 360 w/Zero deck Hyperutecic Fed-Mougal slugs, TF heads, .028 Cometic head gaskets on 93 octane.

View attachment 1715774479

It produces very low CCP

Look at the intake valve opening @ 6* BTDC

If you would like another one I will have one available.

A low CCP? I’m not familiar with that abbreviation.

It was chosen to be modest and perform slightly above stock rpm ranges.

It was chosen to be modest and perform slightly above stock rpm ranges.

512Stroker

We are all here because we are not all there.

CCP = Cranking Cylinder PressureA low CCP? I’m not familiar with that abbreviation.

It was chosen to be modest and perform slightly above stock rpm ranges.

Some my like this cam, for me it did not work.

It pulls hard in the mid range.

Ehhhh, it’s not to bad and pretty OK on the Hwy. where it normally lives. Routinely @ 70-75 mph.

Around town, it is very docile. Moves off the line in normal driving fair enough. The wife normally drops a gear getting in the Hwy. She takes it in and out of work a bunch.

Around town, it is very docile. Moves off the line in normal driving fair enough. The wife normally drops a gear getting in the Hwy. She takes it in and out of work a bunch.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,608

- Reaction score

- 13,849

What's your elevation in Freedom MO?

At 6000ft, you do not have enough Static CR for that Comp XR274HR cam.

At 6000ft, you do not have enough Static CR for that Comp XR274HR cam.

512Stroker

We are all here because we are not all there.

700ft above sea levelWhat's your elevation in Freedom MO?

At 6000ft, you do not have enough Static CR for that Comp XR274HR cam.

Fixed.Sorry couldn't rotate photo

This is a Racer Brown solid flat tappet purchased from a member ( new with lifters , it will be for a future project ) .

View attachment 1715772498

View attachment 1715774896

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,608

- Reaction score

- 13,849

>I have seen hydraulic rollers with ramps from "advertised to .050s", of between 53degrees and to over 80 degrees, per pair (opening plus closing).

In the Comp case above, you are looking at 274 less 224=50*@.050....... but at the advertised, the valves are still stated to be, .006 open! So you gotta watch those specs like a hawk!

I think this is an unfair practice, but what do I know. Why? Because you think you are buying a 274/282/110, but if the valves are not yet closed, then what are you actually getting? This cam may act like a 274/282/110 after 3000rpm, but what if the intake valve doesn't close for another 8 or 12 or 16 flipping degrees.... This is how you get unhappy streeters. They think they are buying a 224 at .050, but not all 224@.050s are equals.

My guess is that the ramps are very very slow, from .006 to on the seat and not leaking. Lets say the opening ramp is another 10* long; a conservative number, that would make the Ica, at plus 4 degrees advanced, to be 73* ; which is pretty late.

With a 73* Ica, the Wallace predicts 153psi CCP, and a VP of just 112; which will make the engine feel like a 318LA at under 3000/3400 rpm; so you will need a bit of a stall to get past that.

Sooooooo, if you want to run this 274 cam, 153psi leaves plenty of room for improvement in the Scr.

Butum if the ramps are longer, well it will just be more doggie.

Now:

Swapping to a solid-roller lifter will cure that , but now you have a different problem; namely, with the same .050 numbers, your intake valve may close too early and very likely your pressure will be too high.

For solid rollers, I have seen numbers from Zero-lash to .050 of as little a 39 degrees. If you happen to get one of those, then the 224@.050 becomes 263 at zero-lash, so if a 110 cam installed at 106, then the Ica becomes 57.5, and the Wallace predicts over 180psi with a now very healthy VP of 153.....

But you cannot run 180psi with iron heads, on pump gas at WOT.

That will take alloy heads.

So now, with a solid roller, and iron heads, you are sorta forced (at 10.5Scr) to go bigger on the .050 to get the intake valves actually closed on the seats, a lil LATER.

In the Comp case above, you are looking at 274 less 224=50*@.050....... but at the advertised, the valves are still stated to be, .006 open! So you gotta watch those specs like a hawk!

I think this is an unfair practice, but what do I know. Why? Because you think you are buying a 274/282/110, but if the valves are not yet closed, then what are you actually getting? This cam may act like a 274/282/110 after 3000rpm, but what if the intake valve doesn't close for another 8 or 12 or 16 flipping degrees.... This is how you get unhappy streeters. They think they are buying a 224 at .050, but not all 224@.050s are equals.

My guess is that the ramps are very very slow, from .006 to on the seat and not leaking. Lets say the opening ramp is another 10* long; a conservative number, that would make the Ica, at plus 4 degrees advanced, to be 73* ; which is pretty late.

With a 73* Ica, the Wallace predicts 153psi CCP, and a VP of just 112; which will make the engine feel like a 318LA at under 3000/3400 rpm; so you will need a bit of a stall to get past that.

Sooooooo, if you want to run this 274 cam, 153psi leaves plenty of room for improvement in the Scr.

Butum if the ramps are longer, well it will just be more doggie.

Now:

Swapping to a solid-roller lifter will cure that , but now you have a different problem; namely, with the same .050 numbers, your intake valve may close too early and very likely your pressure will be too high.

For solid rollers, I have seen numbers from Zero-lash to .050 of as little a 39 degrees. If you happen to get one of those, then the 224@.050 becomes 263 at zero-lash, so if a 110 cam installed at 106, then the Ica becomes 57.5, and the Wallace predicts over 180psi with a now very healthy VP of 153.....

But you cannot run 180psi with iron heads, on pump gas at WOT.

That will take alloy heads.

So now, with a solid roller, and iron heads, you are sorta forced (at 10.5Scr) to go bigger on the .050 to get the intake valves actually closed on the seats, a lil LATER.

Last edited:

-

Similar threads

- Locked

[FOR SALE]

383-440 Mopar Performance Purple cam shaft.

- Replies

- 1

- Views

- 1K

- Replies

- 0

- Views

- 461

- Locked

- Replies

- 5

- Views

- 2K

- Locked

- Replies

- 4

- Views

- 2K

- Replies

- 0

- Views

- 714