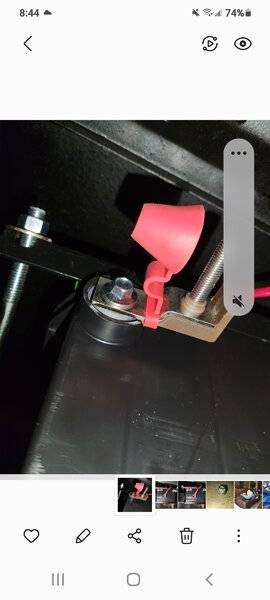

Ok, all good questions and ideas, I do actually own a carbon pile load tester at my shop we use them for boats all the time, mine is a smaller, portable Napa brand so we can take it in and out of boats, but same idea so I could try your idea 67dart273, as to WHY I decided to add this is simply because the battery is on the frame on a bracket mounted on the passenger side of the cab, the four gauge cable goes into the engine compartment and across the firewall down to the starter, probably a run of 8 feet? IF the truck were to ever to be hit on the passenger side and stuffed in about 6 inchs then the post could contact the door, OR if at any time the positive cable were to rub through at the firewall, same result, in marine the wire running from the Stern of the boat where the batteries are to the front is always protected by a fuse in case the feed wire going up front is comprised . I am just adding some safety against electrical shorting. So as far as a heavy duty breaker goes I did think of that to but thought on the off chance this thing would ever trip I would be fine with a fuse.....I was wrong, but now that I already have the fuse maybe I'll upgrade to the bigger amp and try it then if it works and know what size I need I'll get a breaker, thanks for the help and ideas.