I recently used the MSD 8.5mm wire 'kit' on an engine. Extra long leads, cut to size & fit the dist lug. One of the leads measured high resistance at the spark plug terminal, which is assembled my MSD [ & obviously not checked ] prior to shipping. These leads use fine copper wire which is enamel covered. The enamel is an insulator. I scrape off the enamel to bare copper for a good connection.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need some opinions on where to go from here...

- Thread starter mshred

- Start date

-

SRT_DSTRHOLC

"There is never enough horsepower...."

Seems like he might have figured it out

mshred

The Green Manalishi

- Joined

- May 2, 2008

- Messages

- 3,310

- Reaction score

- 177

Nope not yet. Hopefully this weekend. Been a busy week at work, and it's Thanksgiving this weekend here.Seems like he might have figured it out

mshred

The Green Manalishi

- Joined

- May 2, 2008

- Messages

- 3,310

- Reaction score

- 177

Been a while since I posted a reply in here to this, and just wanted to update on what actually happened, and where I am most likely going from here.

Got the car running a few weeks ago- tons of smoke out the exhaust, and missing on cylinders 2, 4, and 3. Checked over a few things like wires and plugs to make sure everything was in the right spot, and still no difference...Car ran like a bag of ****, and this time, I just so happened to have cardboard under the car (gravel driveway) and there was black all over it, which appeared to be oil. Car also seemed to be running PIG rich, obviously would not idle with missing on those 3 cylinders (a temperature gun on each header tube revealed this). The oil out the exhaust had me concerned, but I thought I would try one more thing, so I pulled all the plugs, cleaned them good, and put on another carburetor (a known good running carb)...This time, cylinder 3 started firing, but 2 and 4 were still dead, and the oil coming out the exhaust was worse. Didn't really try much more then that.

I picked up a running 5.9 magnum the other day for a great deal. I also thought I would pull the headers to see which cylinders seem to have the issue with oil, and maybe inspect those valve seals in particular...Then I got thinking, I mine as well pull the entire top end to check over all the valves and seals and also finish enlarging some of the pushrod holes that were tight.

I am going to conclude that my bottom end is okay based on the leak downs and compressions tests that I did, and truly hope my issue is in the top end, can get fixed, and I have a running car. But if that fails, I will use the Magnum engine I just picked up and work with that. This car was supposed to be a milder cruiser street/strip deal to take the family out to car shows, ice cream, etc. so I want it running and well.

Thanks to all for the insight, tips, and advice! Truly hoping I pull the heads, find something super obvious, and its an easy fix that addresses everything!

Got the car running a few weeks ago- tons of smoke out the exhaust, and missing on cylinders 2, 4, and 3. Checked over a few things like wires and plugs to make sure everything was in the right spot, and still no difference...Car ran like a bag of ****, and this time, I just so happened to have cardboard under the car (gravel driveway) and there was black all over it, which appeared to be oil. Car also seemed to be running PIG rich, obviously would not idle with missing on those 3 cylinders (a temperature gun on each header tube revealed this). The oil out the exhaust had me concerned, but I thought I would try one more thing, so I pulled all the plugs, cleaned them good, and put on another carburetor (a known good running carb)...This time, cylinder 3 started firing, but 2 and 4 were still dead, and the oil coming out the exhaust was worse. Didn't really try much more then that.

I picked up a running 5.9 magnum the other day for a great deal. I also thought I would pull the headers to see which cylinders seem to have the issue with oil, and maybe inspect those valve seals in particular...Then I got thinking, I mine as well pull the entire top end to check over all the valves and seals and also finish enlarging some of the pushrod holes that were tight.

I am going to conclude that my bottom end is okay based on the leak downs and compressions tests that I did, and truly hope my issue is in the top end, can get fixed, and I have a running car. But if that fails, I will use the Magnum engine I just picked up and work with that. This car was supposed to be a milder cruiser street/strip deal to take the family out to car shows, ice cream, etc. so I want it running and well.

Thanks to all for the insight, tips, and advice! Truly hoping I pull the heads, find something super obvious, and its an easy fix that addresses everything!

MOPAROFFICIAL

If it has tits, it's a liabilititty.

Whos thinking what im thinking..

.. and how many of you are familiar with our friend "mshred"

.. and how many of you are familiar with our friend "mshred"

mshred

The Green Manalishi

- Joined

- May 2, 2008

- Messages

- 3,310

- Reaction score

- 177

Huh?Whos thinking what im thinking..

.. and how many of you are familiar with our friend "mshred"

Please, enlighten me with what you're thinking

B3422w5

Well-Known Member

Very familiar with him. He has posted on Moparts for years, and is a quality poster.Whos thinking what im thinking..

.. and how many of you are familiar with our friend "mshred"

mshred

The Green Manalishi

- Joined

- May 2, 2008

- Messages

- 3,310

- Reaction score

- 177

Thanks man! It's been a while, I mostly lurk now, since I find unless I have truly good advice that speaks from true experience, it's best to just say nothing. Otherwise the search tab usually gets me by.Very familiar with him. He has posted on Moparts for years, and is a quality poster.

SRT_DSTRHOLC

"There is never enough horsepower...."

Sounds like you're ready to pull the heads. Just do it and report back.

B3422w5

Well-Known Member

Thanks man! It's been a while, I mostly lurk now, since I find unless I have truly good advice that speaks from true experience, it's best to just say nothing. Otherwise the search tab usually gets me by.

Did you ever do a gen3 deal?

Have you pulled the rocker arm shaft or loosened it to ensure there is no load on the valve when your leak testing the poor cylinder at anything but tdc?Alright, so back with an update...

First thing I did while waiting to borrow a good battery (here I was cleaning terminals, meanwhile it was a bad battery that would drop in voltage from 12.5 to 4 in under a minute after taking a charger off of it) was run another leak down test on cylinder number 6 a couple nights ago...As soon as I got it to top dead center, again using my small bore scope, I put the air to it, and it leaked less than 5% like all the other cylinders. So then I backed it up a bit to before TDC and the 70% leak was back....back to TDC and the leak was gone again...a bit past TDC, and it leaked. One more time right back, and all good at least then 5%. So then I added oil to the cylinder just to see what might happen, and readings based on piston position were EXACTLY the same as without the oil, literally made no difference- at TDC all good, just before or after and no bueno. When the leak was at 70% I left the rad cap off and had the cylinder filled for almost 10mins- zero bubbling of water in the rad. No sound out the exhaust, no air out the crankcase, no air out the intake/carb..It just seemed like air kinda at the valves is where the sound was..Also, since it was mentioned, when I did the initial leakdown test, I actually tested each cylinder twice and the numbers all repeated. Only cylinder 6 was the one I had trouble with, but now seems to be alright at TDC.

Today with the good battery in I ran a compression test on the engine, and just like the leakdown, with a completely cold engine. EVERY CYLINDER cranked 155-160psi. When the engine was hot, cylinder 4 was 20psi less, and I could swear the numbers were at 125psi, with cylinder 4 at 100psi, but stupid me, didn't write it down. This is a late 70s 360 with cast flat dish pistons down the hole about .110". With the thin MP head gaskets I'm running and the cylinder head chamber measurements, I'm right at aboit 8.9:1 compression, and with a 230/236 at .050" cam the cold compression numbers seem EXTRA healthy in my opinion. I did not bother to run a compression test with oil in the cylinders since honestly it seemed to me that it cranked awesome for what the build is.

Valve covers were off and I had the wife turning the key for the compression test so I could watch the test gauge and also watch the rockers. To the naked eye, valvetrain appears to be working alright, but really I don't think I'd spot anything unless something was very visibly bad. Lash on all the valves is set equal, and none required more or less adjustment, so that has me hopeful there is no bad lobes on the cam.

Here are my conclusions, and I'd like your opinions on whether you agree or think I should be checking something else...

It would seem to me that with the healthy numbers on the cold compression test, and finally getting cylinder 6 to leak down like the others, that my issue is either ignition related or valvetrain related (like possibly a bent push rod from the holes not being enlarged enough and making contact while it was running, or the contact of the pushrod in the hole hanging it up just enough to not allow the valves to open and close properly). Also thinking it could be a bad valve job or valve seals, since when the car was running the odd bank of cylinders had a lot of smoke out that side of the exhaust. Comparing my cold compression test numbers to what I recall the hot numbers were, it seems maybe because cylinder 4 wasn't firing as evidenced by the white plug, that maybe that's why it was down compared to the other cylinders that were all hot and seemed to be firing. I'm thinking the bottom end is sealing, and so are my head gaskets, and the bad leakdown on cylinder 6 was maybe carbon on the valves or just enough valve opening with the piston not perfectly at TDC to create a leak. Maybe the bottom end can stay together, but yanking the heads at this point to further enlarge the pushrod holes on all of them, as well as checking the valve seals and valve job, is a good idea? Gives me a chance to inspect the cam lobes as well to check if they wore in with lifters properly.

Interested to hear what you guys think. Appreciate the insight and patience reading my short saga here to help me out. Long day, pretty sure I'm not forgetting anything lol

If your concerned with the head gasket, you can borrow a cooling system pressure test kit from O'Rileys, but it will be limited as it will not detect a poor sealing fire ring.

The other question would be the condition of the lobes on the poor cylinder. I'm guessing your running a hydraulic cam.

I've seen this come up in discussion before: https://forums.yesterdaystractors.com/threads/caterpillar-part-no-7f5225-break-in-powder.1043529/

mshred

The Green Manalishi

- Joined

- May 2, 2008

- Messages

- 3,310

- Reaction score

- 177

Was trying everything in my power to not have to, especially since these heads are studded and this engine bay isn't the friendliest for that, but with winter around the corner and finally having heat in my shop, im going inSounds like you're ready to pull the heads. Just do it and report back.

The scamp has a forged piston 5.7 long block with a D1x procharger with an air to water intercooler, 727 and Holley terminator engine management, but that's not running either lol. Got real close, but was getting ready to move...been a year since I moved but have still been busy with house stuff and the family take up most of my time. It's just odds and ends left to button up really, hoping I can get it ready to fire up in the spring over the winter as well.Did you ever do a gen3 deal?

I have not yet. I actually have to borrow my friends leak down tester for something else I was planning to do on the engine, so now that I've decided it's coming apart I may as check that as well. I'm hoping when I pull the heads the gasket would show obvious signs, but I'm not sure it's that at this point. The oil in the exhaust is a big red flag. The cam was an old crane hydraulic that I had reground at Oregon and is now a solid flat tappet- something else pulling the heads and intake will reveal, if I have a bad lobe, but the rocker adjustments are all the same, doesn't seem to be one with more play or requiring more adjustment to it. I will check out that link...thanks!Have you pulled the rocker arm shaft or loosened it to ensure there is no load on the valve when your leak testing the poor cylinder at anything but tdc?

If your concerned with the head gasket, you can borrow a cooling system pressure test kit from O'Rileys, but it will be limited as it will not detect a poor sealing fire ring.

The other question would be the condition of the lobes on the poor cylinder. I'm guessing your running a hydraulic cam.

I've seen this come up in discussion before: https://forums.yesterdaystractors.com/threads/caterpillar-part-no-7f5225-break-in-powder.1043529/

mygasser

Well-Known Member

have you pulled the intake? if the gasket's leaking underneath the intake it'll suck oil into the cylinders. it could be as simple as that.

neil.

neil.

mshred

The Green Manalishi

- Joined

- May 2, 2008

- Messages

- 3,310

- Reaction score

- 177

I was actually thinking about that the other day. It has to come off before the heads do, so hopefully its something that simple! I really just thought I would try everything possible first before tearing into things. but now that I have committed to a tear down, I should hopefully find my issue pretty easily (Hopefully!)have you pulled the intake? if the gasket's leaking underneath the intake it'll suck oil into the cylinders. it could be as simple as that.

neil.

Jarlaxle

Well-Known Member

OK...I have a hail Mary play, if the mill is still together. If so...hook up the air, pump up the cylinder that won't hold pressure, and look in the radiator cap. Bet a dollar you'll see bubbles.Yes, but if its not audibly coming from the exhaust, the carb, or the crankcase, could it not just be leaking right at the valve enough to cause the leak but not really have it felt or heard in the usual spots?

mshred

The Green Manalishi

- Joined

- May 2, 2008

- Messages

- 3,310

- Reaction score

- 177

Already did that...waited over 10 mins...nothing...OK...I have a hail Mary play, if the mill is still together. If so...hook up the air, pump up the cylinder that won't hold pressure, and look in the radiator cap. Bet a dollar you'll see bubbles.

SRT_DSTRHOLC

"There is never enough horsepower...."

Do all the cylindersAlready did that...waited over 10 mins...nothing...

Jarlaxle

Well-Known Member

And on that note, I am out of brilliant ideas.Already did that...waited over 10 mins...nothing...

SRT_DSTRHOLC

"There is never enough horsepower...."

It could be a heat and expanding issue. There could be a section that when it heats up it's allowing something in because of some vaporAnd on that note, I am out of brilliant ideas.

Jarlaxle

Well-Known Member

Maybe not...I really don't expect this will work, but it would cost nothing and take less than an hour: maybe try retorquing the heads?Already did that...waited over 10 mins...nothing...

skep419

5.9 Magnum 4 speed afficionado

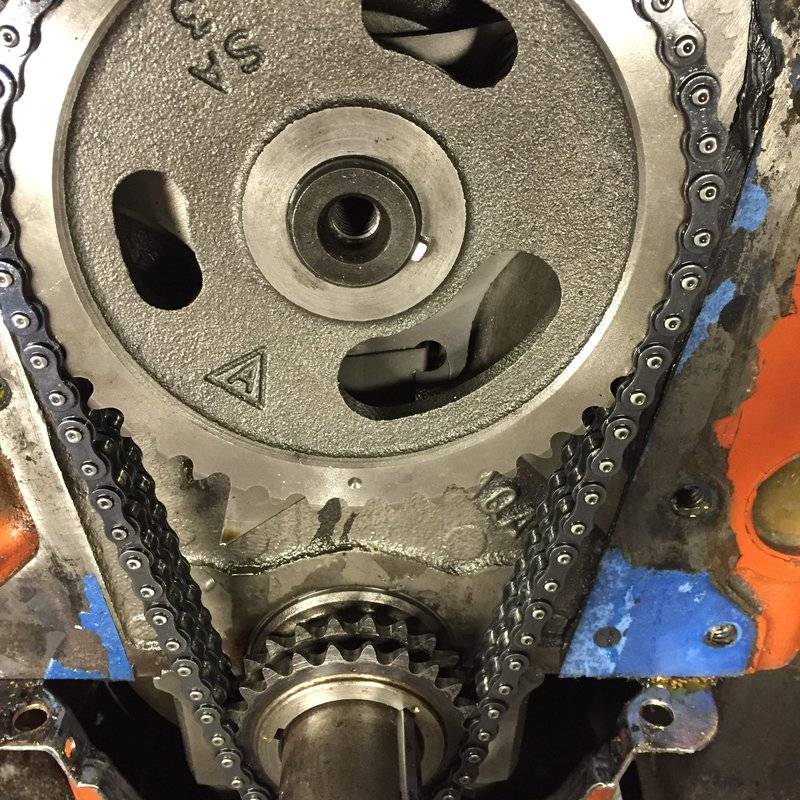

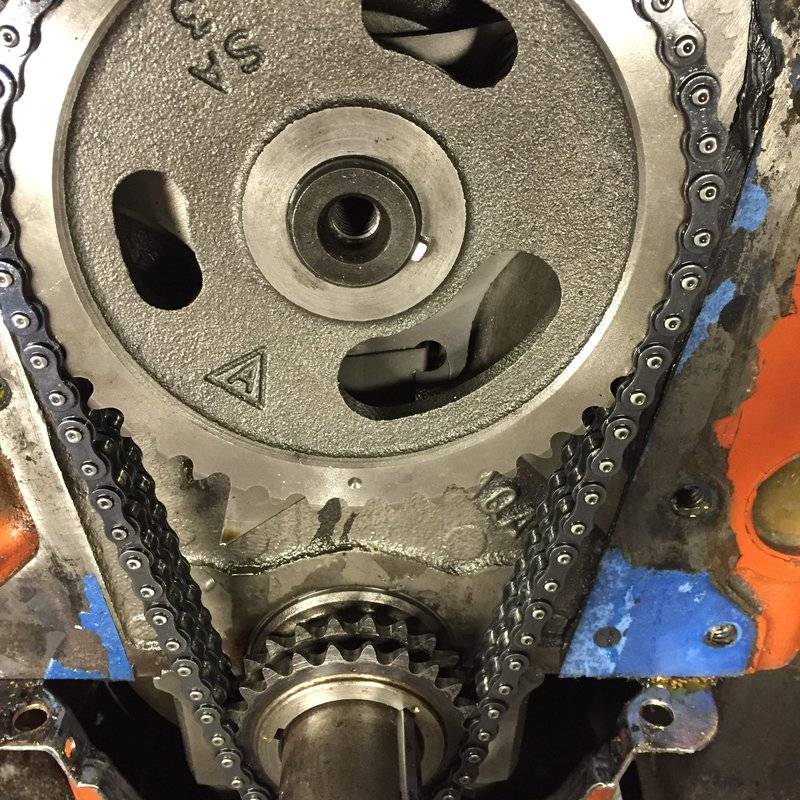

Not sure if it's been brought up already but could the cam be degreed in wrong? (Not sure it would cause any smoke but.....)

The dots on some of the inexpensive chains are hard to see. The first engine I ever had built the shop lined them up and it ran like garbage.

The dots on some of the inexpensive chains are hard to see. The first engine I ever had built the shop lined them up and it ran like garbage.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,608

- Reaction score

- 13,849

I'll tell you what I would do before I started taking things apart.

I'm NOT telling you what you should do, and IDK why no one has mentioned this yet, and yes I read the entire thread.

As for the oil getting sucked up from the valley

here is an easy test; Just flip the PCV out of it's grommet, and plug both valve covers. Then, put a vacuum gauge on the dipstick-tube. and get the engine running.

In this condition, the CC should begin to build pressure, as blow-by begins to pressurize it. If you see vacuum, badaboom the intake is the culprit.

As to the why of it, well that needs more diagnostic.

At Idle, pressure is usually slow to build, but if it goes past 3psi, often by 4psi, it wants to blow something out so, STOP the test before it blows the rear cam plug out. I'm NOT paying somebody to re-install it.

Now; if the pressure pops up right away, You gotta suspect a gouged cylinder wall.

As to the odd Leakdown test.

I would do it again but this time, with all the valve gear removed. By doing it this way, the compressed air will blow the piston down to the bottom, into the area of nearly new cylinder walls, and you can almost ignore ringseal. Now, if you measure leakage, you can almost bet, that it's a valve.

Furthermore, with the piston at the bottom you can now tap the valves down, and on the LD gauge, see instantly if anything changes. PLUS, if something does change, you will hear it in the change of the sound that the valve makes when it slaps back onto the seat. A sealing valve makes an energetic slap at 100psi that is impossible to miss. I don't even bother with the LD gauge until I find a suspect valve.

And finally, if you do not find a leaking valve using this method, nor a leaking headgasket etcetera, then, you gotta go look for a cylinder-wall gouge. I do this by reducing the test pressure to about 30psi, then slowly bringing up the piston, stopping about every half inch and holding it there while watching the LD gauge. If the LD is the same from bottom to top, then that cylinder is not gouged.

But with the piston held stationary, if at any time the gauge pressure drops, that's a problem.

Don't forget that when you go to reinstall the valve gear, the shafts need to be correctly oriented.

That's what I would do.

*******************************

Now, just FYI;

I run a similar cam (230/237/110 Hughes, in straight up) on my 11/1 Edelbrock, alloy-headed 367. It really came alive with the RPM AirGap, and a 750DP. I won't say it revs willingly to over 7000, cuz it makes RRR sick to hear that, but sometimes I even hold it to 7200.

But what I will say, is that in Second gear (manual-trans, 1.92 x 3.55= 6.82 Roadgear), it will initiate tirespin at up to 55mph with just a foot-stomp, even with up to 325s.

The point is this;

if you ever get that beotch running right, and yur running 245s,

be vewy vewy caweful on your maiden voyage. As in; do not stomp your 750DP carb while cornering, cuz a skinny-tired A-Body will spin you around lickity-split, and in traffic, that's a little crazy; don't ask me how I know, lol. Remember, I didn't mention 7200, at all.

Mum's the word about 7000.

Furthermore; and just so you know what is possible;

A) with a 223/230/110 cam, in at 106, I ran my alloy heads at up to 195psi , in a street car. and

B) With the current 230* cam, now in straight up, I have managed to whittle it down to 180>185, cuz at 195, and with a clutch, it was hard to drive at slow speeds.

If yur really at 9.8Scr and your Ica is 62* (your cam in at 106), and say you are at 500ft elevation; Then the Wallace Calculator predicts your CCP to be 163psi. Every time I use that calculator, it has been within a very few percent of what I read on my gauge.

So then,

with iron heads, for most of us guys, 163 psi with a tight quench, is pushing the limit for pumpgas.

But if your alloy-headed low-compression 360 has to come apart anyway, then I'd be re-engineering it for 195psi, cuz mine runs on 87E10, at full-timing, at that pressure, which makes scary big torque; which is perfect for a lo-stall, hiway geared Dual-Purpose, mostly DD, A-Body.

Just so you know;

I'm Not telling you that you gotta run there.

I'm just saying what's possible, cuz I already did it, over 100,000 miles ago. Nor is this a brag, Rusty, I really don't care if you vomit all over yourself, again.

I'm NOT telling you what you should do, and IDK why no one has mentioned this yet, and yes I read the entire thread.

As for the oil getting sucked up from the valley

here is an easy test; Just flip the PCV out of it's grommet, and plug both valve covers. Then, put a vacuum gauge on the dipstick-tube. and get the engine running.

In this condition, the CC should begin to build pressure, as blow-by begins to pressurize it. If you see vacuum, badaboom the intake is the culprit.

As to the why of it, well that needs more diagnostic.

At Idle, pressure is usually slow to build, but if it goes past 3psi, often by 4psi, it wants to blow something out so, STOP the test before it blows the rear cam plug out. I'm NOT paying somebody to re-install it.

Now; if the pressure pops up right away, You gotta suspect a gouged cylinder wall.

As to the odd Leakdown test.

I would do it again but this time, with all the valve gear removed. By doing it this way, the compressed air will blow the piston down to the bottom, into the area of nearly new cylinder walls, and you can almost ignore ringseal. Now, if you measure leakage, you can almost bet, that it's a valve.

Furthermore, with the piston at the bottom you can now tap the valves down, and on the LD gauge, see instantly if anything changes. PLUS, if something does change, you will hear it in the change of the sound that the valve makes when it slaps back onto the seat. A sealing valve makes an energetic slap at 100psi that is impossible to miss. I don't even bother with the LD gauge until I find a suspect valve.

And finally, if you do not find a leaking valve using this method, nor a leaking headgasket etcetera, then, you gotta go look for a cylinder-wall gouge. I do this by reducing the test pressure to about 30psi, then slowly bringing up the piston, stopping about every half inch and holding it there while watching the LD gauge. If the LD is the same from bottom to top, then that cylinder is not gouged.

But with the piston held stationary, if at any time the gauge pressure drops, that's a problem.

Don't forget that when you go to reinstall the valve gear, the shafts need to be correctly oriented.

That's what I would do.

*******************************

Now, just FYI;

I run a similar cam (230/237/110 Hughes, in straight up) on my 11/1 Edelbrock, alloy-headed 367. It really came alive with the RPM AirGap, and a 750DP. I won't say it revs willingly to over 7000, cuz it makes RRR sick to hear that, but sometimes I even hold it to 7200.

But what I will say, is that in Second gear (manual-trans, 1.92 x 3.55= 6.82 Roadgear), it will initiate tirespin at up to 55mph with just a foot-stomp, even with up to 325s.

The point is this;

if you ever get that beotch running right, and yur running 245s,

be vewy vewy caweful on your maiden voyage. As in; do not stomp your 750DP carb while cornering, cuz a skinny-tired A-Body will spin you around lickity-split, and in traffic, that's a little crazy; don't ask me how I know, lol. Remember, I didn't mention 7200, at all.

Mum's the word about 7000.

Furthermore; and just so you know what is possible;

A) with a 223/230/110 cam, in at 106, I ran my alloy heads at up to 195psi , in a street car. and

B) With the current 230* cam, now in straight up, I have managed to whittle it down to 180>185, cuz at 195, and with a clutch, it was hard to drive at slow speeds.

If yur really at 9.8Scr and your Ica is 62* (your cam in at 106), and say you are at 500ft elevation; Then the Wallace Calculator predicts your CCP to be 163psi. Every time I use that calculator, it has been within a very few percent of what I read on my gauge.

So then,

with iron heads, for most of us guys, 163 psi with a tight quench, is pushing the limit for pumpgas.

But if your alloy-headed low-compression 360 has to come apart anyway, then I'd be re-engineering it for 195psi, cuz mine runs on 87E10, at full-timing, at that pressure, which makes scary big torque; which is perfect for a lo-stall, hiway geared Dual-Purpose, mostly DD, A-Body.

Just so you know;

I'm Not telling you that you gotta run there.

I'm just saying what's possible, cuz I already did it, over 100,000 miles ago. Nor is this a brag, Rusty, I really don't care if you vomit all over yourself, again.

Good idea!I'll tell you what I would do before I started taking things apart.

I'm NOT telling you what you should do, and IDK why no one has mentioned this yet, and yes I read the entire thread.

As for the oil getting sucked up from the valley

here is an easy test; Just flip the PCV out of it's grommet, and plug both valve covers. Then, put a vacuum gauge on the dipstick-tube. and get the engine running.

In this condition, the CC should begin to build pressure, as blow-by begins to pressurize it. If you see vacuum, badaboom the intake is the culprit.

As to the why of it, well that needs more diagnostic.

At Idle, pressure is usually slow to build, but if it goes past 3psi, often by 4psi, it wants to blow something out so, STOP the test before it blows the rear cam plug out. I'm NOT paying somebody to re-install it.

Now; if the pressure pops up right away, You gotta suspect a gouged cylinder wall.

As to the odd Leakdown test.

I would do it again but this time, with all the valve gear removed. By doing it this way, the compressed air will blow the piston down to the bottom, into the area of nearly new cylinder walls, and you can almost ignore ringseal. Now, if you measure leakage, you can almost bet, that it's a valve.

Furthermore, with the piston at the bottom you can now tap the valves down, and on the LD gauge, see instantly if anything changes. PLUS, if something does change, you will hear it in the change of the sound that the valve makes when it slaps back onto the seat. A sealing valve makes an energetic slap at 100psi that is impossible to miss. I don't even bother with the LD gauge until I find a suspect valve.

And finally, if you do not find a leaking valve using this method, nor a leaking headgasket etcetera, then, you gotta go look for a cylinder-wall gouge. I do this by reducing the test pressure to about 30psi, then slowly bringing up the piston, stopping about every half inch and holding it there while watching the LD gauge. If the LD is the same from bottom to top, then that cylinder is not gouged.

But with the piston held stationary, if at any time the gauge pressure drops, that's a problem.

Don't forget that when you go to reinstall the valve gear, the shafts need to be correctly oriented.

That's what I would do.

*******************************

Now, just FYI;

I run a similar cam (230/237/110 Hughes, in straight up) on my 11/1 Edelbrock, alloy-headed 367. It really came alive with the RPM AirGap, and a 750DP. I won't say it revs willingly to over 7000, cuz it makes RRR sick to hear that, but sometimes I even hold it to 7200.

But what I will say, is that in Second gear (manual-trans, 1.92 x 3.55= 6.82 Roadgear), it will initiate tirespin at up to 55mph with just a foot-stomp, even with up to 325s.

The point is this;

if you ever get that beotch running right, and yur running 245s,

be vewy vewy caweful on your maiden voyage. As in; do not stomp your 750DP carb while cornering, cuz a skinny-tired A-Body will spin you around lickity-split, and in traffic, that's a little crazy; don't ask me how I know, lol. Remember, I didn't mention 7200, at all.

Mum's the word about 7000.

Furthermore; and just so you know what is possible;

A) with a 223/230/110 cam, in at 106, I ran my alloy heads at up to 195psi , in a street car. and

B) With the current 230* cam, now in straight up, I have managed to whittle it down to 180>185, cuz at 195, and with a clutch, it was hard to drive at slow speeds.

If yur really at 9.8Scr and your Ica is 62* (your cam in at 106), and say you are at 500ft elevation; Then the Wallace Calculator predicts your CCP to be 163psi. Every time I use that calculator, it has been within a very few percent of what I read on my gauge.

So then,

with iron heads, for most of us guys, 163 psi with a tight quench, is pushing the limit for pumpgas.

But if your alloy-headed low-compression 360 has to come apart anyway, then I'd be re-engineering it for 195psi, cuz mine runs on 87E10, at full-timing, at that pressure, which makes scary big torque; which is perfect for a lo-stall, hiway geared Dual-Purpose, mostly DD, A-Body.

Just so you know;

I'm Not telling you that you gotta run there.

I'm just saying what's possible, cuz I already did it, over 100,000 miles ago. Nor is this a brag, Rusty, I really don't care if you vomit all over yourself, again.

mshred

The Green Manalishi

- Joined

- May 2, 2008

- Messages

- 3,310

- Reaction score

- 177

I already re torqued the heads after the first initial break in...Maybe not...I really don't expect this will work, but it would cost nothing and take less than an hour: maybe try retorquing the heads?

Cam was degreed with a wheel, triple checked since sometimes even two times is not enough to trust myself lol.Not sure if it's been brought up already but could the cam be degreed in wrong? (Not sure it would cause any smoke but.....)

The dots on some of the inexpensive chains are hard to see. The first engine I ever had built the shop lined them up and it ran like garbage.

Been working the past few weeks to get heat in my shop, but this weekend I'm planning to do another leakdown without valve gear, and begin a slow disassembly. I'm not firing it up again as is...if you saw the smoke coming out of the exhaust, you'd think you were at a Metallica concert for the opening song. Something is WAY off...I'll tell you what I would do before I started taking things apart.

I'm NOT telling you what you should do, and IDK why no one has mentioned this yet, and yes I read the entire thread.

As for the oil getting sucked up from the valley

here is an easy test; Just flip the PCV out of it's grommet, and plug both valve covers. Then, put a vacuum gauge on the dipstick-tube. and get the engine running.

In this condition, the CC should begin to build pressure, as blow-by begins to pressurize it. If you see vacuum, badaboom the intake is the culprit.

As to the why of it, well that needs more diagnostic.

At Idle, pressure is usually slow to build, but if it goes past 3psi, often by 4psi, it wants to blow something out so, STOP the test before it blows the rear cam plug out. I'm NOT paying somebody to re-install it.

Now; if the pressure pops up right away, You gotta suspect a gouged cylinder wall.

As to the odd Leakdown test.

I would do it again but this time, with all the valve gear removed. By doing it this way, the compressed air will blow the piston down to the bottom, into the area of nearly new cylinder walls, and you can almost ignore ringseal. Now, if you measure leakage, you can almost bet, that it's a valve.

Furthermore, with the piston at the bottom you can now tap the valves down, and on the LD gauge, see instantly if anything changes. PLUS, if something does change, you will hear it in the change of the sound that the valve makes when it slaps back onto the seat. A sealing valve makes an energetic slap at 100psi that is impossible to miss. I don't even bother with the LD gauge until I find a suspect valve.

And finally, if you do not find a leaking valve using this method, nor a leaking headgasket etcetera, then, you gotta go look for a cylinder-wall gouge. I do this by reducing the test pressure to about 30psi, then slowly bringing up the piston, stopping about every half inch and holding it there while watching the LD gauge. If the LD is the same from bottom to top, then that cylinder is not gouged.

But with the piston held stationary, if at any time the gauge pressure drops, that's a problem.

Don't forget that when you go to reinstall the valve gear, the shafts need to be correctly oriented.

That's what I would do.

*******************************

Now, just FYI;

I run a similar cam (230/237/110 Hughes, in straight up) on my 11/1 Edelbrock, alloy-headed 367. It really came alive with the RPM AirGap, and a 750DP. I won't say it revs willingly to over 7000, cuz it makes RRR sick to hear that, but sometimes I even hold it to 7200.

But what I will say, is that in Second gear (manual-trans, 1.92 x 3.55= 6.82 Roadgear), it will initiate tirespin at up to 55mph with just a foot-stomp, even with up to 325s.

The point is this;

if you ever get that beotch running right, and yur running 245s,

be vewy vewy caweful on your maiden voyage. As in; do not stomp your 750DP carb while cornering, cuz a skinny-tired A-Body will spin you around lickity-split, and in traffic, that's a little crazy; don't ask me how I know, lol. Remember, I didn't mention 7200, at all.

Mum's the word about 7000.

Furthermore; and just so you know what is possible;

A) with a 223/230/110 cam, in at 106, I ran my alloy heads at up to 195psi , in a street car. and

B) With the current 230* cam, now in straight up, I have managed to whittle it down to 180>185, cuz at 195, and with a clutch, it was hard to drive at slow speeds.

If yur really at 9.8Scr and your Ica is 62* (your cam in at 106), and say you are at 500ft elevation; Then the Wallace Calculator predicts your CCP to be 163psi. Every time I use that calculator, it has been within a very few percent of what I read on my gauge.

So then,

with iron heads, for most of us guys, 163 psi with a tight quench, is pushing the limit for pumpgas.

But if your alloy-headed low-compression 360 has to come apart anyway, then I'd be re-engineering it for 195psi, cuz mine runs on 87E10, at full-timing, at that pressure, which makes scary big torque; which is perfect for a lo-stall, hiway geared Dual-Purpose, mostly DD, A-Body.

Just so you know;

I'm Not telling you that you gotta run there.

I'm just saying what's possible, cuz I already did it, over 100,000 miles ago. Nor is this a brag, Rusty, I really don't care if you vomit all over yourself, again.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,608

- Reaction score

- 13,849

If you have done any repairs looking for the problem, don't forget that the mufflers and exhaust system, will be full of condensed oil, and as soon as the pipes get some heat in them, that oil will begin to smoke. There's no telling how long it will take to burn off.

-

Similar threads

- Replies

- 224

- Views

- 13K

- Replies

- 26

- Views

- 2K

- Replies

- 8

- Views

- 956

- Replies

- 36

- Views

- 3K