TXOval

340 stroked to 416

About to put a Holley Super Sniper kit on my 340…I’ll report back how it goesThanks, Glad you enjoyed it, Yes the next build should be injected. starting off TBI, then going to ITB's - Port injection as time and $ allow.

About to put a Holley Super Sniper kit on my 340…I’ll report back how it goesThanks, Glad you enjoyed it, Yes the next build should be injected. starting off TBI, then going to ITB's - Port injection as time and $ allow.

Shapin up! What will you use for an oil pump?1/5/23:

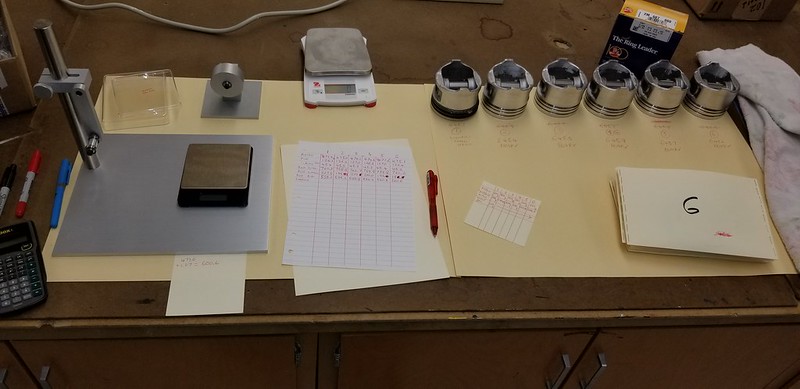

Making a bit more progress before it goes to the Machine Shop:

View attachment 1716030719

View attachment 1716030720

Broke out all of the porting tools..

View attachment 1716030721

View attachment 1716030722

Cleaned up and checked Stock Oil Pump with pressure relief valve set / shimmed to my liking.Shapin up! What will you use for an oil pump?

Which stock one? The 5/8" or 7/8" rotor? Inquirin minds wanna know. lolCleaned up and checked Stock Oil Pump with pressure relief valve set / shimmed to my liking.

Sounds Good, Eventually I want to Have a Megasquirt III Running Full sequential on ITB's but I have to $ave up some More ca$h for that. Hopefully this summer I can get the MSIII running a single 4 Bbl TBI setup. I contemplated having Gill Welding medifying the current manifold for MPEFI, but I feel my money would be misplaced as I should just go straight from the TBI to the ITB intake and DCOE TB's with InjectorsAbout to put a Holley Super Sniper kit on my 340…I’ll report back how it goes

Probably the small rotor - No Need to create excessive load on the crappy Cam / Oil pump gear interface.Which stock one? The 5/8" or 7/8" rotor? Inquirin minds wanna know. lol

Have you seen this one?Sounds Good, Eventually I want to Have a Megasquirt III Running Full sequential on ITB's but I have to $ave up some More ca$h for that. Hopefully this summer I can get the MSIII running a single 4 Bbl TBI setup. I contemplated having Gill Welding medifying the current manifold for MPEFI, but I feel my money would be misplaced as I should just go straight from the TBI to the ITB intake and DCOE TB's with Injectors

I have a bunch of parts to make the EFI Happen, (MSII Box, In tank fuel pump module Fitech Throttlebody with injectors, just need some input sensors and, relay board, wiring and triggers etc. and then time to do the install and swap.

Did you see my oiling mod to my latest engine build? I put a piston squirter aimed right at the cam and oil pump gears.Probably the small rotor - No Need to create excessive load on the crappy Cam / Oil pump gear interface.

Here's what I did. I believe that will "address" the problem.Probably the small rotor - No Need to create excessive load on the crappy Cam / Oil pump gear interface.

It's a Volkswagen part number. Either of these:@RustyRatRod

Did not see your oiling mod, but thanks for sharing, it Looks good. I might hafta Try that. What is the application for the piston squirter / Part# ?

No I have never heard of mcgee racing, But Thanks for sharing. Those parts are a bit rich for my budget right now...I already have 3 of the DCOE Clifford manifolds and Most of the other requite EFI parts - I just need about $1200 for the DCOE Throttle Bodies and injectors.

Which grinds did you get? I'm fixin to get #549 for my next engine, but ground on a 106.2/3/23:

Oregon Cam Grinding Called.

My Order of 3 Camshafts is done and was shipped out yesterday.

Just now waiting on the local Machine Shop, for the Block and Crank work which may take a bit longer. Also Dropped of the machine shop content 2 weeks later than the Cams so ~ 4 weeks turnaround for the 3 cams and 24 Lifters to be reground was good for me.

Well, we have another thing in common besides slant sixes. I have dyslexia too.3 of the same. I have to look at my notes. they are different lobes on the cam that I have from my buddy. I really like it for a stockish bottom end with a good sized head.

I can never remember all of those numbers with out having them in front of me plus my dyslexia will probably mix something up.

I've made similar mistakes. A lot. lol That's why I've learned to double and triple check.One time on the ruster engine I timed the cam for the # 1 Exhaust valve instead of intake. - one mix up I was not happy about.

Yeah. Like that. LOL