You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1970 Swinger 340 Hemi Orange 4 speed

- Thread starter Hemiorangeswinger

- Start date

-

txstang84

Well-Known Member

I believe your resto thread will, along with a few others on here, become a heavily viewed "how to" thread on replacing most welded sheet metal. I'm still waiting for that guy to reply to me about the hubcaps...

340sFastback

Well-Known Member

Outstanding work!! Car has come a long way!

Hemiorangeswinger

Dodge Material

Thanks for the compliments guys!

Well I guess he thinks you're helping me try to get them... Maybe we'll wait another 6 months and email him again? I'm sure nobody will buy those hubcaps at all, except me. Haha.

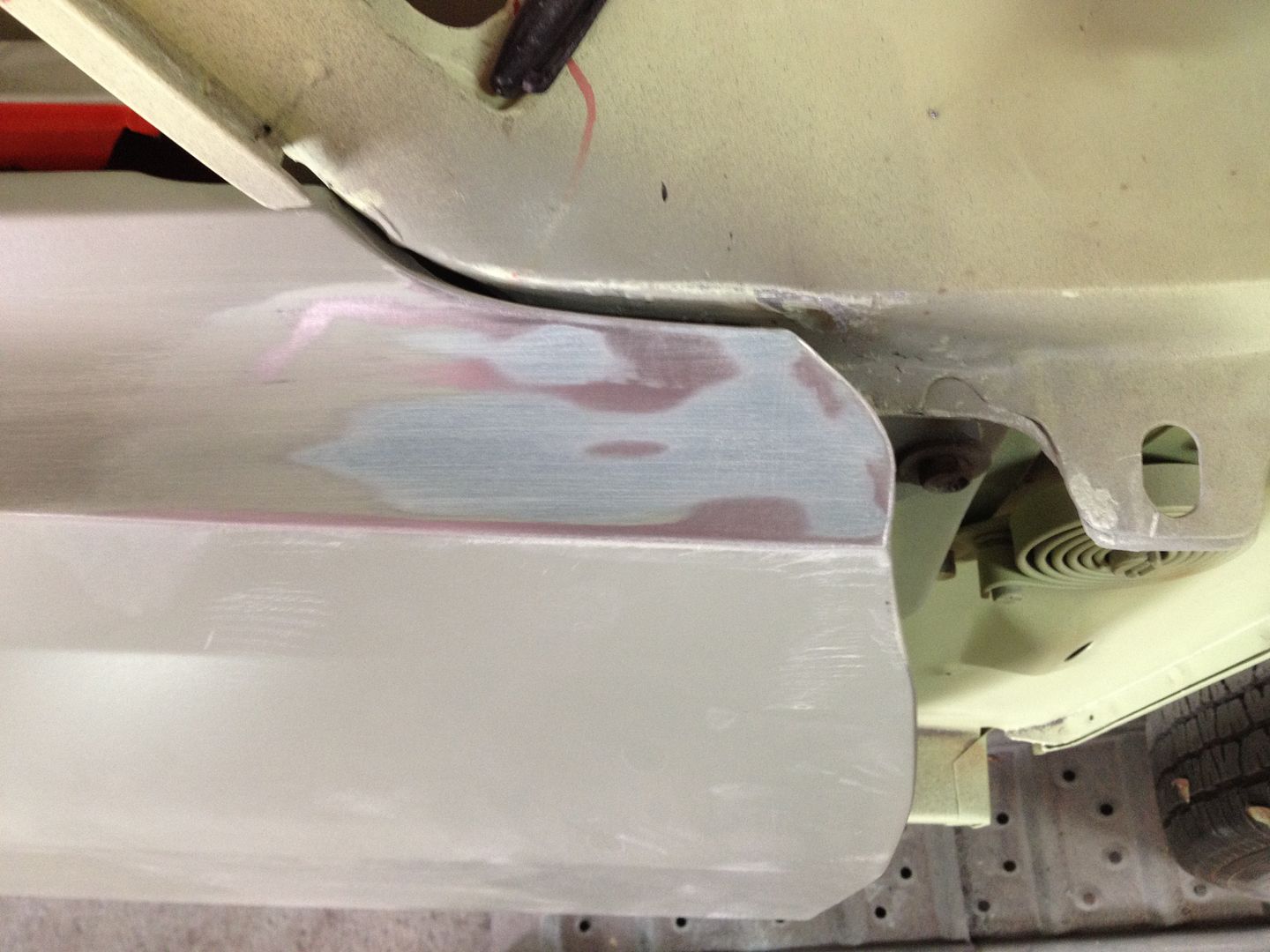

I got the door gap fixxed! It was a ton of welding and cooling with a wet rag so I didn't ruin my panel glue in the flange.

Nice 3/16" gap.

Well I guess he thinks you're helping me try to get them... Maybe we'll wait another 6 months and email him again? I'm sure nobody will buy those hubcaps at all, except me. Haha.

I got the door gap fixxed! It was a ton of welding and cooling with a wet rag so I didn't ruin my panel glue in the flange.

Nice 3/16" gap.

txstang84

Well-Known Member

On to the roof, yes?

Yeah, that guy...if he doesn't reply to my email by about Tuesday (this time) I'm just going to call him...he clearly doesn't have much desire to actually sell anything if he won't reply to people willing to pay for 40 year old parts.

Yeah, that guy...if he doesn't reply to my email by about Tuesday (this time) I'm just going to call him...he clearly doesn't have much desire to actually sell anything if he won't reply to people willing to pay for 40 year old parts.

Hemiorangeswinger

Dodge Material

On to the roof, yes?

Yeah, that guy...if he doesn't reply to my email by about Tuesday (this time) I'm just going to call him...he clearly doesn't have much desire to actually sell anything if he won't reply to people willing to pay for 40 year old parts.

I think I'm going to do the floor pan first, while it's up on the jack stands.

Thanks Jeff, I really appreciate you helping me get those hubcaps! I think they will look really cool on the car and make it stand out... Maybe not in a good way tho, haha. He definitely has some issues!

Applied some glass and epoxy, not it's officially done!

Hemiorangeswinger

Dodge Material

Today was nice out so I decided to push the car outside and clean the garage and wash the floor... It's much nicer starting a new task with a clean garage! I added some extra bracing underneath, I think it might be overkill for a floor pan replacement! Oh well it's just extra material I had laying around.

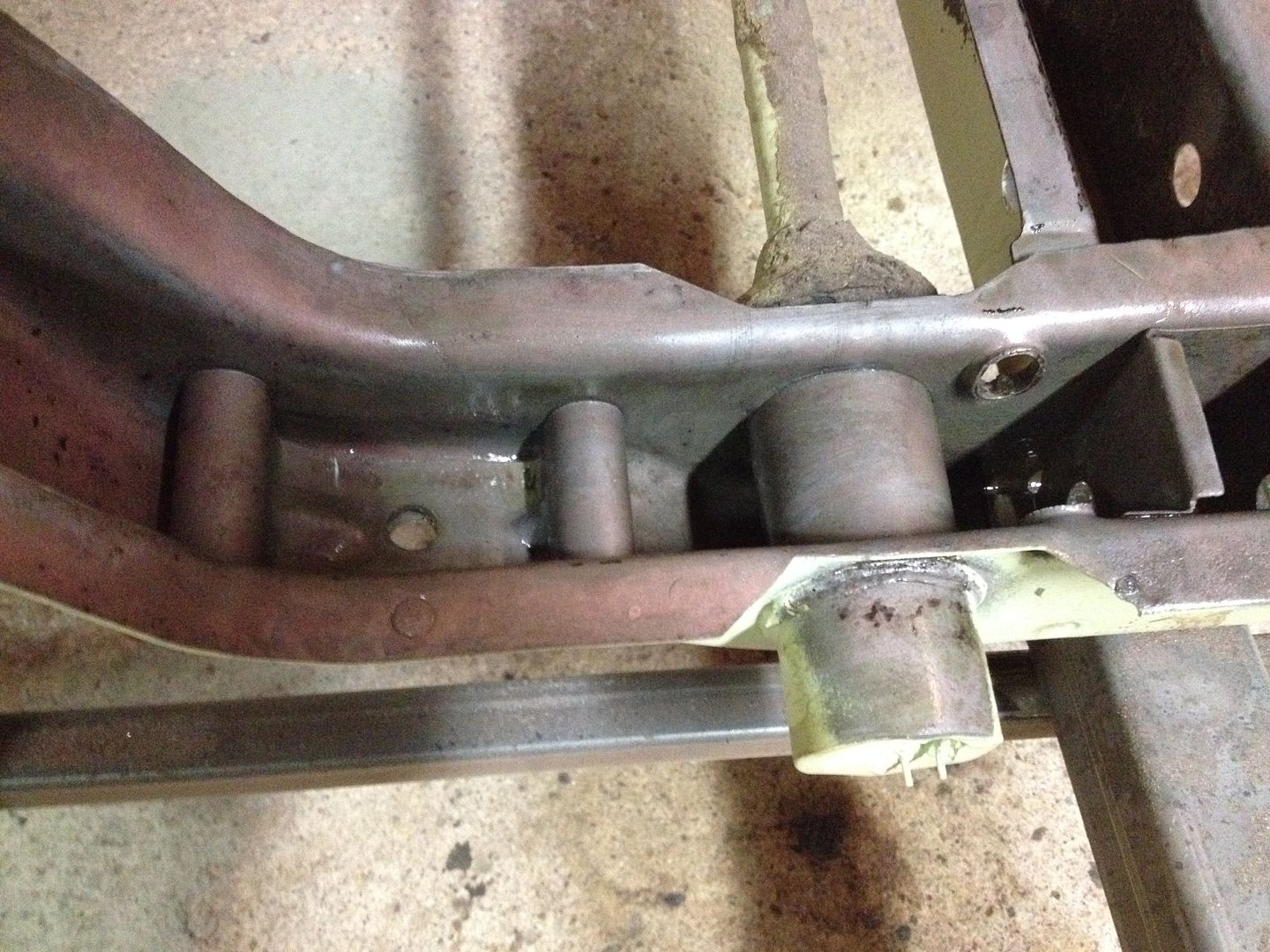

I see I have a repair to do on the torsion bar crossmember... Looks like someone had fun with a cutting torch. Atleast it's not completely cut off in that area.

I see I have a repair to do on the torsion bar crossmember... Looks like someone had fun with a cutting torch. Atleast it's not completely cut off in that area.

340sFastback

Well-Known Member

Impressive work on those door gaps!

Hemiorangeswinger

Dodge Material

Impressive work on those door gaps!

Thanks!!

Today I cleaned up the bench seat brackets that get welded to the inner rocker/floor pan. I got replacements from Lee on this forum. I just had to weld up some spot weld holes, scrape the undercoat off and tomorrow I'll blast them. The original ones on my car (rear ones) were rotted out. I'm not sure how the front brackets are yet. I'll see once the floor comes out.. I got replacements just in case. I also borrowed my Dad's plasma cutter and picked up some new spot weld cutter tips, so the floor will come out fast!

txstang84

Well-Known Member

Mmm plasma cutter-that will indeed make quick work of some rotted sheet metal.

4spdragtop

Well-Known Member

Havent checked in for a while, awesome progress and work!

Hemiorangeswinger

Dodge Material

Mmm plasma cutter-that will indeed make quick work of some rotted sheet metal.

Yeah it saves a lot of time! I've used it on every panel removal so far and it's saved me a lot of money on cuttoff wheels too.

Hey you're doing a great job on the car. Keep it up.

I think that notch in the torsion bar crossmember is supposed to be there for clearance on the 4 speed shifter.

Thanks! I think you're right about the notch for the linkage, but this one appears to be cut a little more then normal.. And it looks like it was done with a cutting torch judging be the slag. I will see what my parts car looks like in this area and will use it for the patch if it needs it.

Havent checked in for a while, awesome progress and work!

Thanks! It's coming along slowly.. I can't wait to be done with all this metal work.

Started cutting the floor out tonight and everything is looking solid! Torsion bar crossmember on the passenger side is nice and clean on the inside (no rust scale) and so is the frame rail. Before I started cutting I released the tension on the torsion bars, since the upper control arms were pressing tight against the bump stop. I backed the bolts off so the control arms weren't touching any bump stops and made sure the car was dead level.

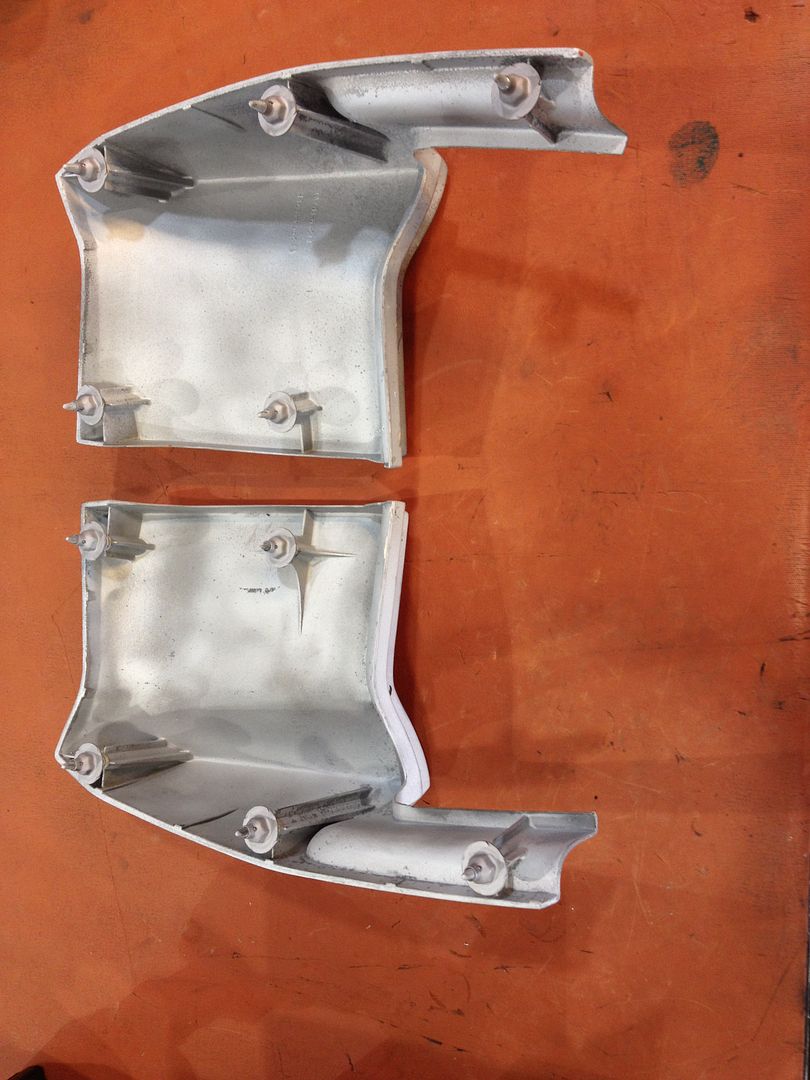

Rusty originals.

Nice used replacements.

Impressive work on those door gaps!

X2! Excellent job on the body. Keep up the good work.

Hemiorangeswinger

Dodge Material

X2! Excellent job on the body. Keep up the good work.

Thanks!!

I got most of the floor out.. It's hard finding spot welds under rust! Tomorrow I will have the rest of it out and hopefully have all the spot welds ground down so I can do a test fit. I think I'm going to add some additional bracing around the torsion bar sockets just for added strength (on the inside) the crossmember is very solid but it can't hurt any adding some extra metal.

Now I can grind down my welds on the inner rockers and finish them nicely.

Templates.

ef8340

Well-Known Member

Randy when you do the template for the floor hump could you show some measurements of where the hole is? to give me an idea of where to cut mine

thanks

thanks

Hemiorangeswinger

Dodge Material

Randy when you do the template for the floor hump could you show some measurements of where the hole is? to give me an idea of where to cut mine

thanks

Will do!

I test fit the floor pan today and it fit perfect. It layed flat all across the torsion bar crossmember and inner rockers. It goes a bit off track around the transmission tunnel/firewall but that's from someone taking a hammer to that seam. I will have some work to do there, but it's not to bad.

Started blasting but ran out of sand. This will take me all week to sandblast everything since I'm using a spot blaster and my compressor needs the odd break so it doesn't over heat

Solid.

Hemiorangeswinger

Dodge Material

Got some more blasting done this afternoon. I'll do some tomorrow and I think I am going to pick up some evaporust, a sump pump and a kids pool so I can let it run thru the crossmember and front rails to get in all the crevices the blaster won't get. I want to get all the rust off inside. I want to do my rear frame rails this way as well, so It won't hurt to get started on this.

Taped off some holes and dumped some evaporust inside the crossmember to get the bottom. As you can see half of it went on the floor, haha. I like the evaporust since it gets into all the pinch weld seams.

Taped off some holes and dumped some evaporust inside the crossmember to get the bottom. As you can see half of it went on the floor, haha. I like the evaporust since it gets into all the pinch weld seams.

Hemiorangeswinger

Dodge Material

Hemiorangeswinger

Dodge Material

txstang84

Well-Known Member

Looks good, Randy! I only hope my rails and such are in good shape too when I get around to that.

76orangewagon

Well-Known Member

Hemiorangeswinger

Dodge Material

Looks good, Randy! I only hope my rails and such are in good shape too when I get around to that.

Thanks! It's always scary cutting out metal because you usually find more surprises.. I found more rust on my drivers side torque box that will need some repairs.

Kind of went the same route with the Duster, except I used Southern Polyurethane Epoxy Primer after Blasting...either way it's protected, glad to see your doing it right. Keep up the good work.

Thanks Ross! I used the rust converter (phosphoric acid on the garage floor wasn't a good idea, haha) since i couldn't get all the rust out, especially the pits in the torque boxes. That rust converter killed everything. I rinsed it all off with water this morning and blew it off, now all the bare metal looks purple and is now protected from flash rusting while I slowly get done with all the metal repairs. Once I do my metal repairs I will scuff it down with a red scotchbrite and epoxy everything with my Chromated glasurit epoxy. Then cover it with some black enamel so you won't see bright green inside the frame from underneath. My inner rockers and torsion bar crossmember came out spotless after sandblasting.

Hemiorangeswinger

Dodge Material

Here's my reinforcement brackets for the drivers side, I still have to make the ones for the passenger side. It's overkill but it can't hurt any.

12ga steel plate.

I'm going to add one more plate across the top to tie my brackets into the other side of the torsion bar socket. I should never have to worry about the torsion bar socket tearing out on this car.

12ga steel plate.

I'm going to add one more plate across the top to tie my brackets into the other side of the torsion bar socket. I should never have to worry about the torsion bar socket tearing out on this car.

Hemiorangeswinger

Dodge Material

Made the top reinforcement plate and applied rust bullet underneath. (Didn't feel like mixing up a tiny amount of epoxy to get in behind the plate) tomorrow once it's dry I will spray some weld thru primer on it and weld it on. I also have to make one for the passenger side.

Over a year on back order from AMD and I finally got it!! I think they're on back order again, hopefully other people don't have to wait as long as I did.

Over a year on back order from AMD and I finally got it!! I think they're on back order again, hopefully other people don't have to wait as long as I did.

-

Similar threads

- Replies

- 38

- Views

- 1K

- Locked

- Replies

- 11

- Views

- 2K

- Replies

- 0

- Views

- 116