You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1972 Duster Build with my Daughter

- Thread starter Jim Kueneman

- Start date

-

Last edited:

What are these two relays on the '73 Dart drivers kick panel way up under the dash?

JDMopar

Well-Known Member

The bottom one looks like a horn relay, and I think the plastic one is a seat belt interlock relay.

The bottom one looks like a horn relay, and I think the plastic one is a seat belt interlock relay.

That was my guess on the metal can since I did not find one in the engine bay like my Coronet has. The 72 would not have that since it did not have the seatbelt light in the dash correct?

JDMopar

Well-Known Member

Correct. Even if you choose to use the later seat belts out of the Dart, it won't matter because the wires on the seat belt retractors won't be plugged into anything. There are better than factory seat belts available, if you kind of want a 3 point belt so she will have a shoulder harness. I've used these belts in 3 of my cars so far, and will be using them in my 70 Duster, and the 65 Barracuda I just bought. Seat Belts Made In USA. Styles And Colors For Most Makes.Call:(302) 629-8508

rebel_scum65

New Member

Definitely keeping an eye on this build as I hope to begin my 72 duster project as well.

Looking great!

Looking great!

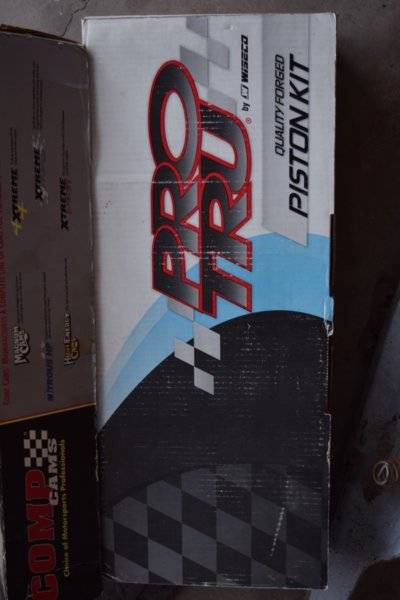

Went to my Mopar drug dealer this morning to get the Title and some goodies for the Duster. Found a straight left bumper bracket, he bought a nice straight bumper filler for Kaelyn to replace the mangled one, shifter linkage that was missing on the Dart, and a few other trinkets we needed. I also picked up the Wiseco Pistons and camshaft for the 318 at a great price from him...

Once I got home we got busy! Kaelyn finished welding in and grinding out the bumper bracket patch while I removed the radiator support sides from the Dart top cross bar. This way the Duster will have the right VIN on the cross bar. The right side radiator support is tacked in before removing the inner fender so the cross support stays in position in 3D. You can see the difference in width. Bob at GlenRay has a set of '73 tanks that are the right part number for a 26" '73 Dart so he will be building up that radiator for the Duster. After than we got the cut up inner fender out we used Aircraft Stripper to start stripping the engine bay. The more I see the B1 blue the more I like it. Lastly we got the LH shock support welded up after someone started to cut it off to reposition for the BB. We are ready for reassembly!

SLOPAR72

Well-Known Member

You literally make me want to crawl under a rock.... You guys are in supersonic speed with the work..... Geeezzz

JW

JW

rapidtransitric

LX/LC platform a body swap pioneer

You literally make me want to crawl under a rock.... You guys are in supersonic speed with the work..... Geeezzz

JW

We have really only put maybe 40 hours (x2) into it (not counting the sandblasting of parts she is doing during the day when I am at work). I also have all the tools to do the job fast which makes a huge difference. With impact tools things come apart FAST.

I was a flat rate mechanic for 10 years I before getting my engineering degree so I learned to use my time wisely or I did not eat.

Last edited:

Correct. Even if you choose to use the later seat belts out of the Dart, it won't matter because the wires on the seat belt retractors won't be plugged into anything. There are better than factory seat belts available, if you kind of want a 3 point belt so she will have a shoulder harness. I've used these belts in 3 of my cars so far, and will be using them in my 70 Duster, and the 65 Barracuda I just bought. Seat Belts Made In USA. Styles And Colors For Most Makes.Call:(302) 629-8508

Yes I want retractable 3 point belts for her in this. Thanks.

Taking my mom out for a dinner theater this afternoon, not much getting done but did remove some of the undercoating from the right inner fender. With all the fancy tools it is still easier just to heat the hell out of the undercoating with a heat gun and scrape it off with a putty knife.....

You literally make me want to crawl under a rock.... You guys are in supersonic speed with the work..... Geeezzz

JW

And if I stop I won't restart!.... also my A Body Mopar drug dealer offered me a '68 Barracuda convertible for a great deal for our next project for the wife...... She wants it....

SLOPAR72

Well-Known Member

We have really only put maybe 40 hours (x2) into it (not counting the sandblasting of parts she is doing during the day when I am at work). I also have all the tools to do the job fast which makes a huge difference. With impact tools things come apart FAST.

I was a flat rate mechanic for 10 years I before getting my engineering degree so I learned to use my time wisely or I did not eat.

One thing that is for sure is to do a restoration project I probably am bringing Nuclear Submarines to a Balloon fight lol..... But leave no doubt that the right tool for the job sure makes things go faster lol.....

If I had a kid who was motivated enough to turn a wrench I myself would probably have fire coming off the end of my tools.... she is a rare one for sure these days so see it through Jim....

JW

I had an eye problem at work today, I could not see spending the week there so I took the rest of the week off. @Kaelyn and I did some cleaning and preping for painting this holiday week/weekend. The garage is cleaned and the parts that need to be sand blasted with the course StarBlast are ready for the cabinet....

Here are my favorite tools of cleaning. The Heat gun and scrapper or air scraper to remove the undercoating and break down the paint. Then a knotted wire brush on the grinder to remove 99% of the old paint and undercoating. This step saves at least 75% of the time needed the sand blasting cabinet and is WAY faster than the sandblaster.

@Kaelyn got a few more parts done tonight.

And I got the rest of the part requiring the StarBlast media for painting. There are a few items to blast with glass beads that need to be done after these are done.

After reading a thread here I realized that the new brake hoses for the disk brakes do NOT fit in the frame tabs on the drum Duster. We need to move the tabs from the Dart to the Duster.... See the difference?

From the Coronet I learned that factory clips are FAR FAR FAR superior to aftermarket. Save ALL clips from disassembly. These are from the hood to radiator seal from the hood.

Lastly I learned not to drink and sandblast tonight. It is very difficult to decide if you are done sandblasting a part after a fifth of Tequila....

Here are my favorite tools of cleaning. The Heat gun and scrapper or air scraper to remove the undercoating and break down the paint. Then a knotted wire brush on the grinder to remove 99% of the old paint and undercoating. This step saves at least 75% of the time needed the sand blasting cabinet and is WAY faster than the sandblaster.

@Kaelyn got a few more parts done tonight.

And I got the rest of the part requiring the StarBlast media for painting. There are a few items to blast with glass beads that need to be done after these are done.

After reading a thread here I realized that the new brake hoses for the disk brakes do NOT fit in the frame tabs on the drum Duster. We need to move the tabs from the Dart to the Duster.... See the difference?

From the Coronet I learned that factory clips are FAR FAR FAR superior to aftermarket. Save ALL clips from disassembly. These are from the hood to radiator seal from the hood.

Lastly I learned not to drink and sandblast tonight. It is very difficult to decide if you are done sandblasting a part after a fifth of Tequila....

Last edited:

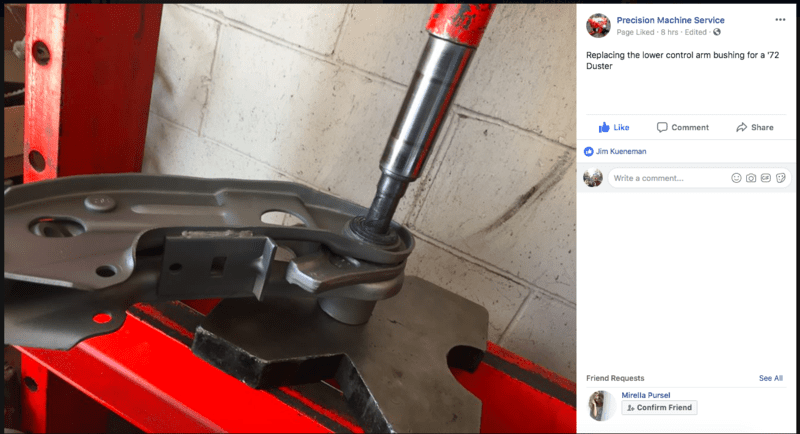

My LCAs are ready with the new bushing, my Toth ported aluminum heads shipped from Pa today and I will drop off the Wisco Piston and Camshaft to Dave at Precision Machine tomorrow. The FirmFeel gear should be shipping in the next few days so we should be able to reassemble the engine/K-Frame in a few weeks.

Long complicated annoying story but the Duster is now titled in my name! Thank you Gingers Title Service in Sierra Vista for actually reading the DMV documents as to what is truly required after the state of Arizona purges a title/VIN/Plate so cleanly they can find no record of it. The burden was on me to get a level one inspection because they throw away records. Gingers did not see where that was necessary when they researched. Anyway done.

I bought 2 flood light housing that are made to install on an electrical junction box for $2.98 each at Lowes, a lamp cord and 2 50W LED flood lamps. I had to steal the nut off one to get the other installed but I drilled a hole it the top of the blasting cabinet and wired in one of the 50W LED bulbs. WHAT A DIFFERENCE. That plus the rope light made the job 10x easier. Tomorrow will install the other 50W and it should be like the surface of the sun in there. Kaelyn will be SO happy. There are only a few more parts to blast. Friday we will start erecting the painting rack so we can spray Saturday!

Dropped the pistons and cam at the machine ship and picked up the LCA with the new MOOG bushing pressed it. Bead blasted and painted, meticulous work by Dave at Precision Machine as always.

I bought 2 flood light housing that are made to install on an electrical junction box for $2.98 each at Lowes, a lamp cord and 2 50W LED flood lamps. I had to steal the nut off one to get the other installed but I drilled a hole it the top of the blasting cabinet and wired in one of the 50W LED bulbs. WHAT A DIFFERENCE. That plus the rope light made the job 10x easier. Tomorrow will install the other 50W and it should be like the surface of the sun in there. Kaelyn will be SO happy. There are only a few more parts to blast. Friday we will start erecting the painting rack so we can spray Saturday!

Dropped the pistons and cam at the machine ship and picked up the LCA with the new MOOG bushing pressed it. Bead blasted and painted, meticulous work by Dave at Precision Machine as always.

Princess Valiant

A.K.A. Rainy Day Auto

Congrats on making the car part of the family, legally.Long complicated annoying story but the Duster is now titled in my name! Thank you Gingers Title Service in Sierra Vista for actually reading the DMV documents as to what is truly required after the state of Arizona purges a title/VIN/Plate so cleanly they can find no record of it. The burden was on me to get a level one inspection because they throw away records. Gingers did not see where that was necessary when they researched. Anyway done.

I bought 2 flood light housing that are made to install on an electrical junction box for $2.98 each at Lowes, a lamp cord and 2 50W LED flood lamps. I had to steal the nut off one to get the other installed but I drilled a hole it the top of the blasting cabinet and wired in one of the 50W LED bulbs. WHAT A DIFFERENCE. That plus the rope light made the job 10x easier. Tomorrow will install the other 50W and it should be like the surface of the sun in there. Kaelyn will be SO happy. There are only a few more parts to blast. Friday we will start erecting the painting rack so we can spray Saturday!

Dropped the pistons and cam at the machine ship and picked up the LCA with the new MOOG bushing pressed it. Bead blasted and painted, meticulous work by Dave at Precision Machine as always.

Too many cars are getting parted and as scrapped these days because of difficulty getting paperwork.

Some states and counties are making it really hard because some people would rather just see all old cars disappear for good.

Congrats on making the car part of the family, legally.

Too many cars are getting parted and as scrapped these days because of difficulty getting paperwork.

Some states and counties are making it really hard because some people would rather just see all old cars disappear for good.

I would not want to go through this too often for sure.

So Dave at Precision Machine posted some of the work he has done over the last few weeks on his Facebook page... The Duster made the grade! This will be way better once he starts posting photos of the 318....

Getting closer to painting. Got everything that we needed to blast with the course stuff for paint adhesion and switched to glass beads. I use them on items that if one get lodged in it the glass will just crush instead of keep grinding away at an important surface...

Cleaned up the shift linkage and mocked it up so I know which way everything goes. I think this is the original fan and clutch. Just needs glass bead blasting to look nice again.

Pulled the gas peddle apart enough to blast the bracket and glass bead blast the cable and housing.

Fan and clutch look original.

Cleaned up the shift linkage and mocked it up so I know which way everything goes. I think this is the original fan and clutch. Just needs glass bead blasting to look nice again.

Pulled the gas peddle apart enough to blast the bracket and glass bead blast the cable and housing.

Fan and clutch look original.

Blasted and ready to paint this weekend. We should play "Do you know your A-Body" and have a part identification contest with this picture

What we have left to do with the glass beads.

Next up are the accessory rebuilds, I use glass beads with these in case one is left behind it won't destroy the item.

Just to document how the bushing go on the shift brackets.

What we have left to do with the glass beads.

Next up are the accessory rebuilds, I use glass beads with these in case one is left behind it won't destroy the item.

Just to document how the bushing go on the shift brackets.

Glenwood

Member

Coming along nicely Jim!

-

Similar threads

- Replies

- 132

- Views

- 3K

- Replies

- 2

- Views

- 226