So dad and I are trying to finish up putting the 273 back together and noticed a difference in the 2 dampeners we got with dads car. You will notice the orientation between the keyway and the timing marks. I remember reading somewhere that if you used a different timing cover that your timing will be out 90*. Any suggestions??

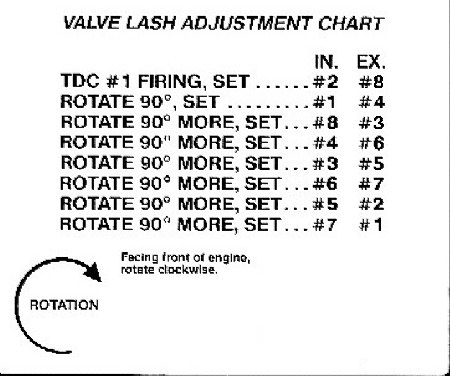

Also we are setting or trying to the valves(solid lifters) on it. I noticed that the rocker arms dont sit totally flat on the valve stems, so when checking the clearance( .021 for exhaust and .013 for intake) do you slide the feeler gauge from the side(parallel to the rocker arm) Or do you slide it in from front to back on the engine?? Also when turning the adjusting screw, should we hold the rocker arm so that it keeps pressure on the pushrod??I know these might be stupid questions, but just trying to be as accurate as possible?? By the way we are setting with feeler gauges, no access to dial indicator.

Thanks again for all your help!

Also we are setting or trying to the valves(solid lifters) on it. I noticed that the rocker arms dont sit totally flat on the valve stems, so when checking the clearance( .021 for exhaust and .013 for intake) do you slide the feeler gauge from the side(parallel to the rocker arm) Or do you slide it in from front to back on the engine?? Also when turning the adjusting screw, should we hold the rocker arm so that it keeps pressure on the pushrod??I know these might be stupid questions, but just trying to be as accurate as possible?? By the way we are setting with feeler gauges, no access to dial indicator.

Thanks again for all your help!