Man! I really enjoy reading FABO from all the crazy discussion threads to the threads where I don't even know what the hell you guys are talking about (seriously it's like there's an inside joke and I'm looking in through the window)

For me it's these build threads, they are compelling and you guys do some outrageous stuff. it Just keeps me energized. BUT, there are those times when you just read and Zonk out.

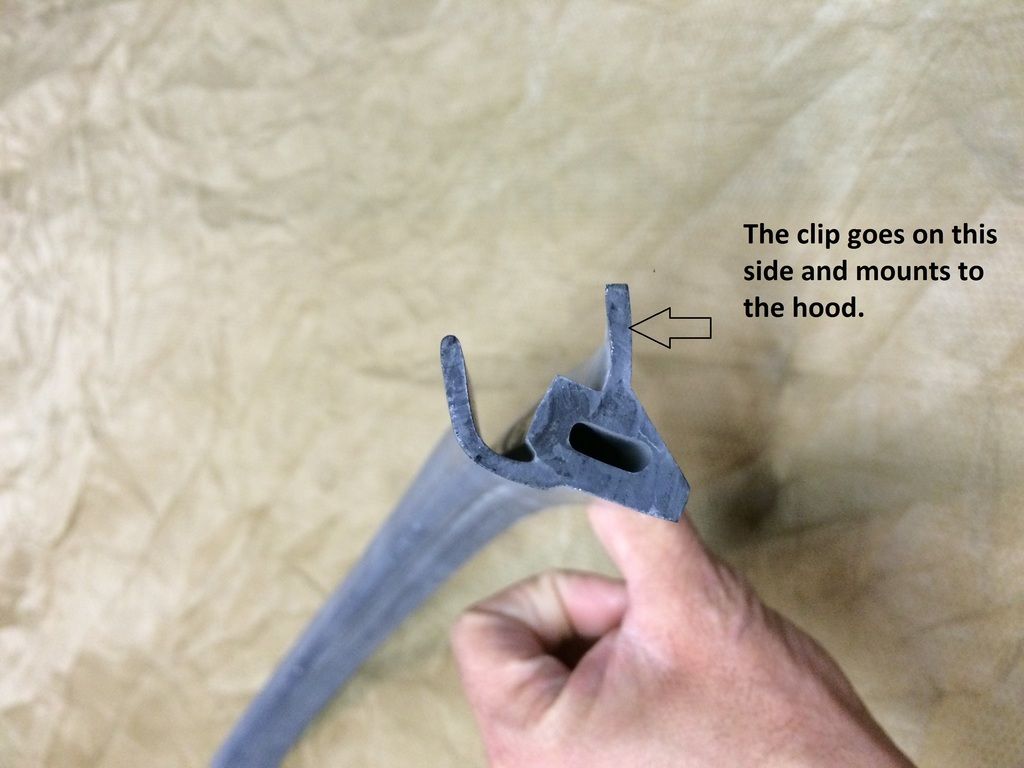

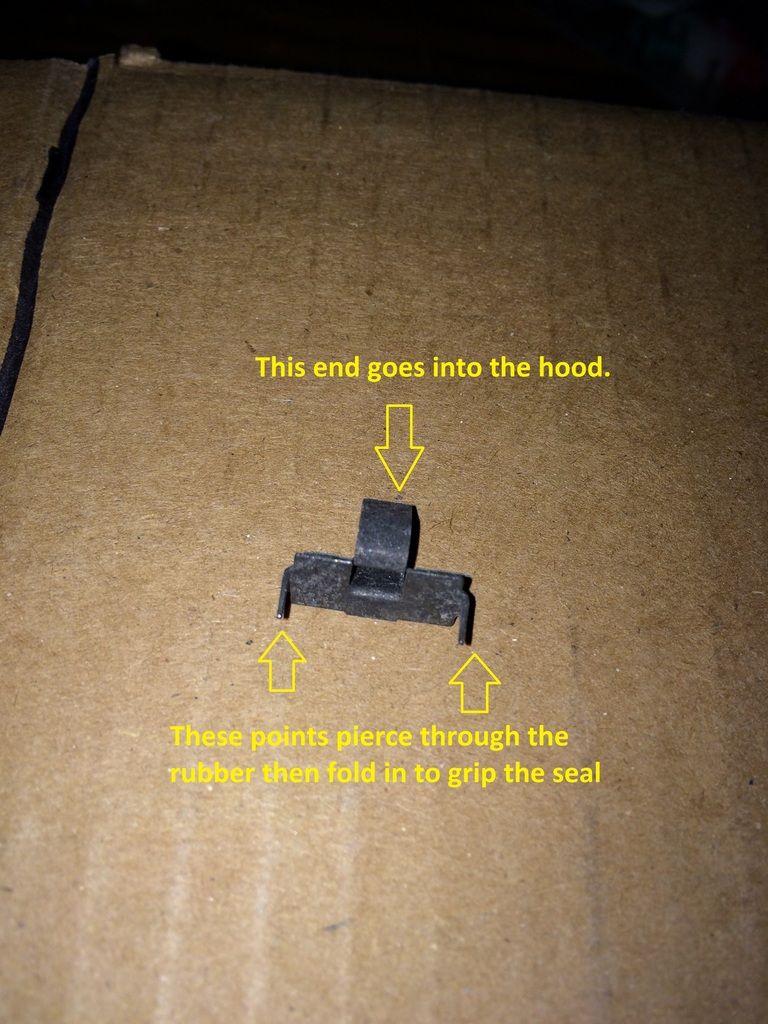

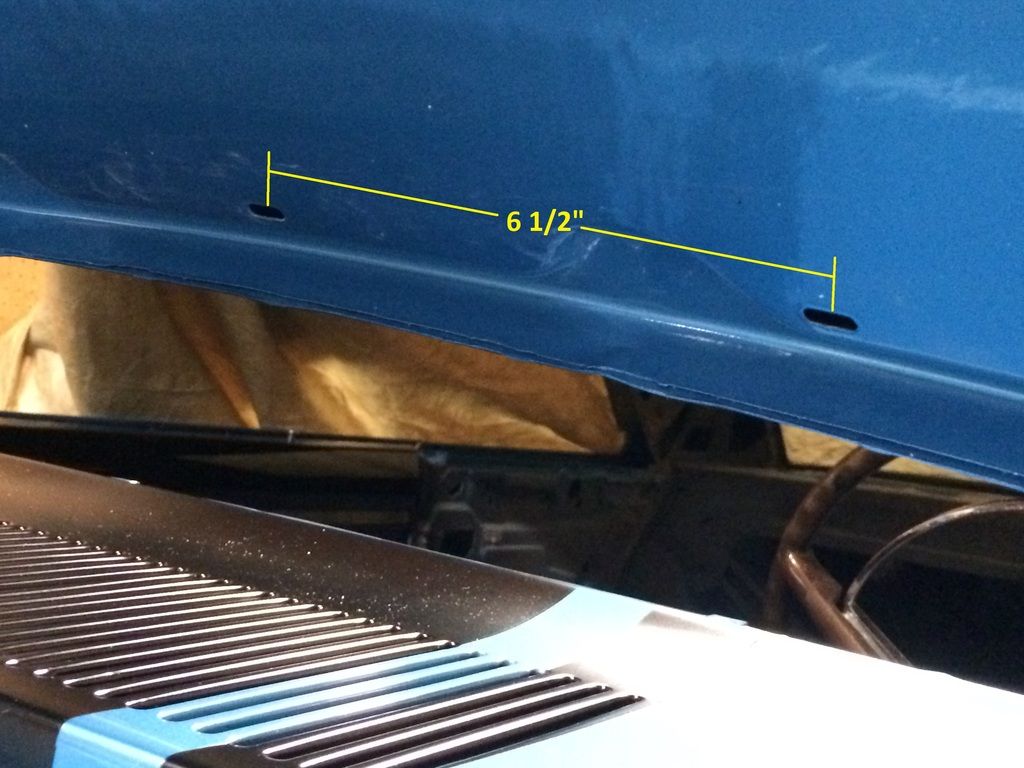

Well I put the old carpet into the car stretched out to take it all in pulled up the laptop to check out what was going on and the next thing I remember is my son hitting me on the face with weather strip .. Man I fell asleep ! LOL they've (he and my wife) been looking for the last 1 and a half!

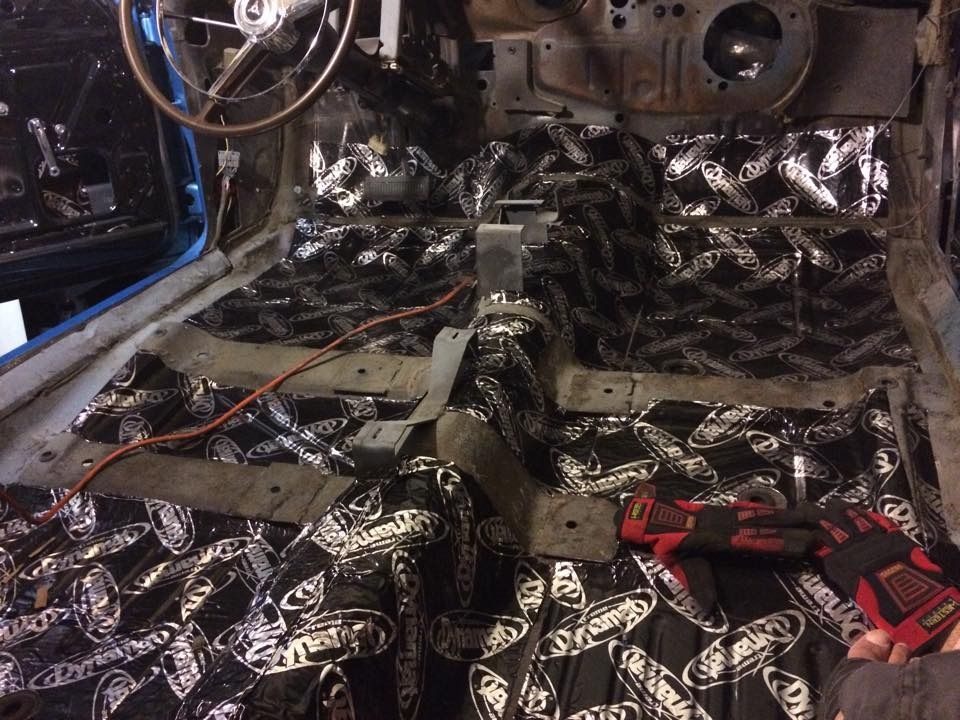

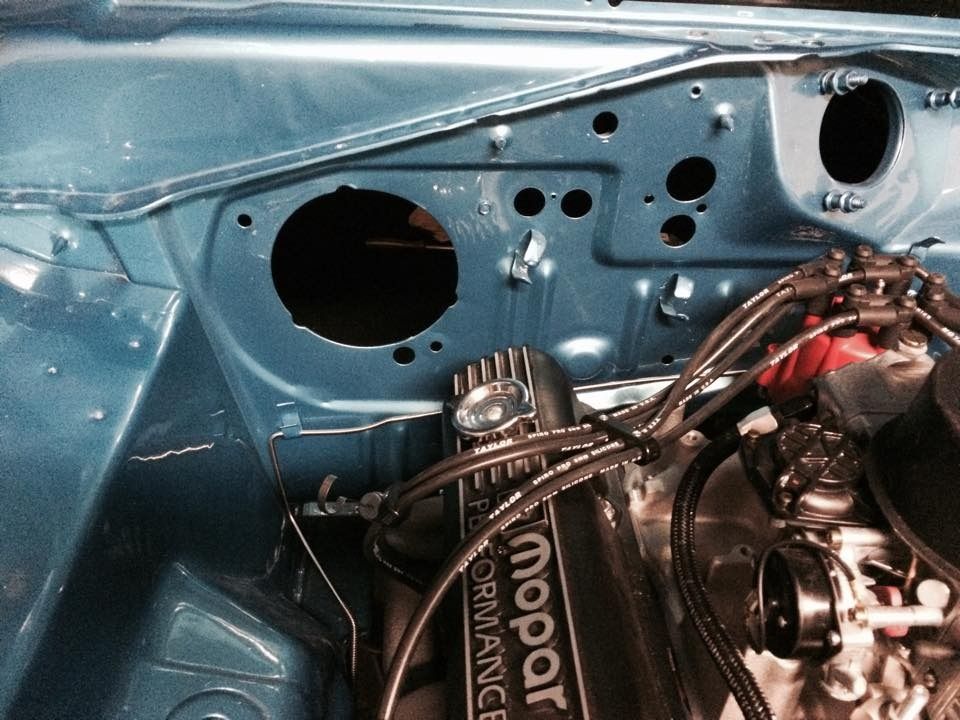

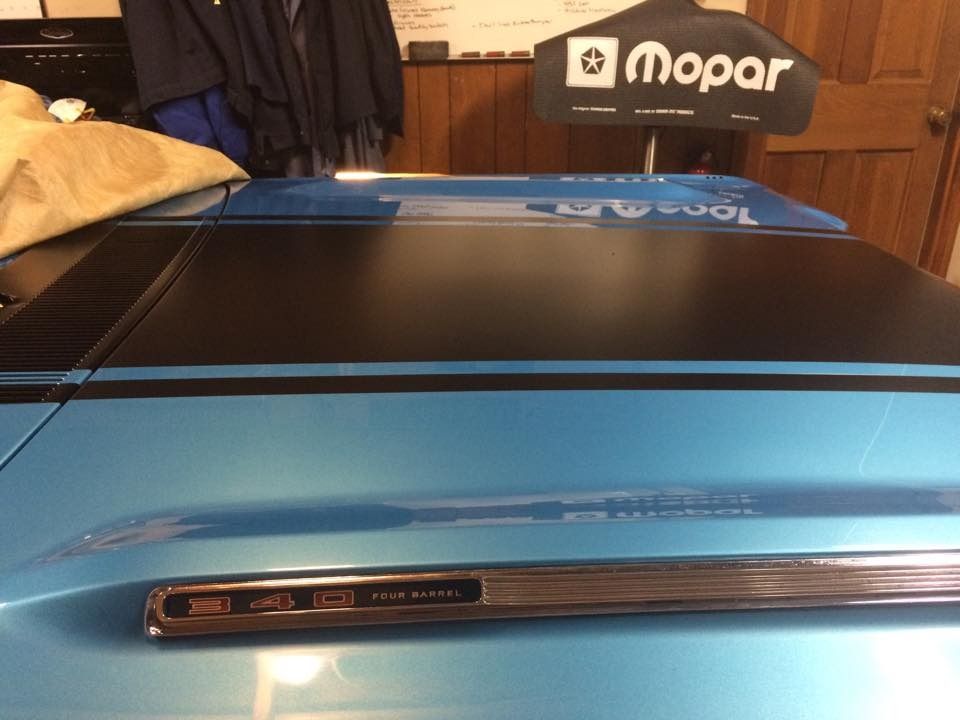

Scene Of the crime.

After checking in and making sure everything was alright I started to work on the Brake system.

Starting with disassemble of the old Master cylinder.

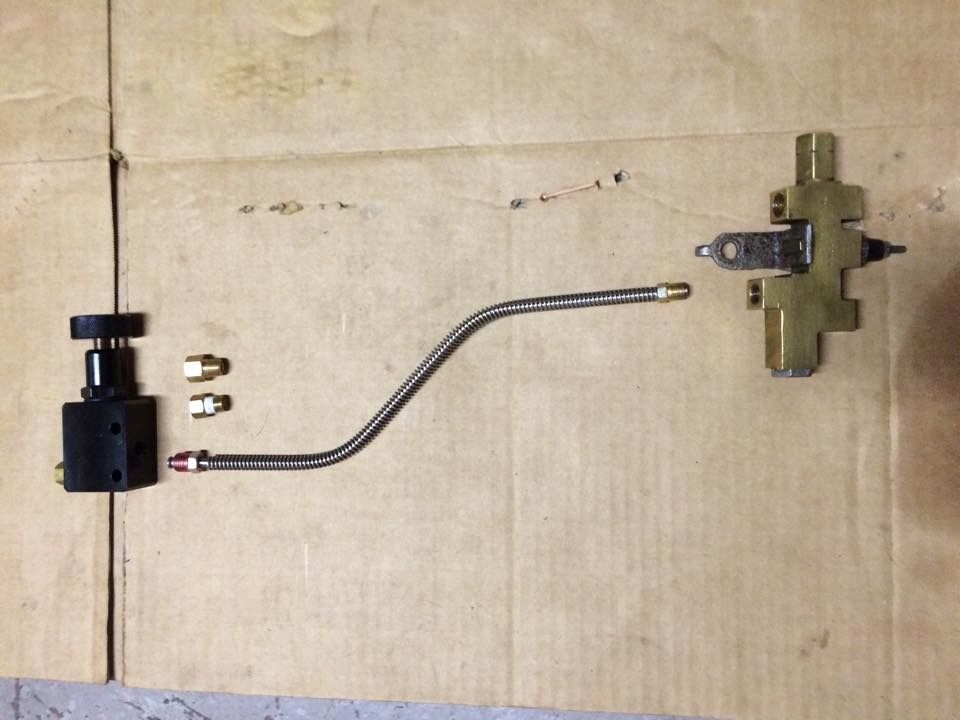

The new setup.

New Master with a 15/16th bore for the disk brakes. It should help the pedal feel.

Had to get the disk brake pro portioning valve to pump more fluid to the disks and less to the rear so the drums don't lock up.

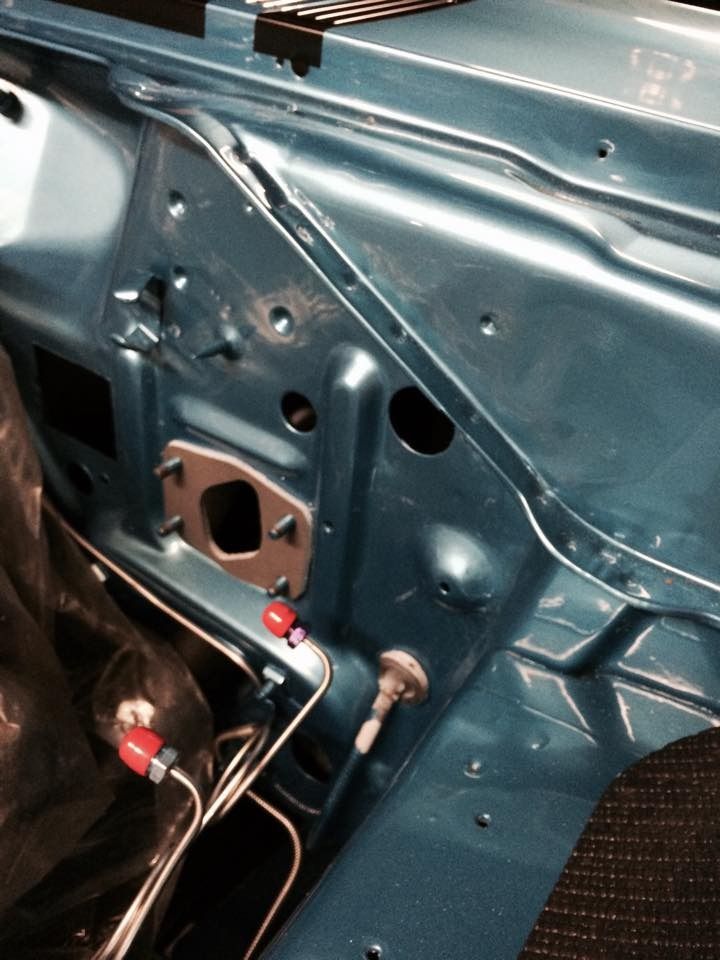

New firewall gasket ( I do eventually get the right gasket) and push rod boot to finish it off.

Front and back Finelines stainless steel brake tubes.

First I'm going to bench test the master cylinder and mount it. Then I'll install these babies and I'll be one step closer to the road.

Brake prop valve and front lines are in. Next is the master cylinder and the rear lines. I do eventually get the correct gasket

)

I went back and fourth on the configuration for a while. First planning to use the combo valve then reverting to keeping the original block and getting an adjustable Prop Valve, which I did, only to come to the realization that the short section of the two piece rear has different fitting on each end to accommodate the factory hold off. More about this later. IN the end I stayed with the Combo valve and worked a solution to couple the two piece front to back section.

The fitting sizes on the short section of the 2pc. Front to rear line set I received from fine lines came with a 3/16 fitting on one end and a 1/4 on the other. The port on the factory block is tapped for the 3/16 end which means the 1/4 end has to join with the long section..

More about the configuration dilemma. I received the adjustable proportioning unit from "Right Stuff" braking, I bought it through Inline Tube since I was ordering the P-Brake hardware anyway.

The P-valve came with 2 - 3/16th adapters but as stated earlier, the short section of the front rear line came with a 3/16 fitting on one end and a 1/4 on the other. So I bought a 1/8mnpt x 1/4 adapter from advance, but it doesn't fit in the P-valve bore which is also a 1/8 mnpt. I'm not sure why, but I am stepping away from this nonsense for now before do something silly. I'll swing by the local advance and rummage through their fittings again but this time I'll bring the P-valve to dry fit.

This would have been the configuration with the stock distribution block) (the combo block is for illustration) notice the different fittings on the short section.

After some digging I found out:

* The adjustable prop valve is tapped for metric M8 (1 0) which is why the 1/8 not didn't work.

* The short section with the 1/4 in fitting is correct for the input of the factory hold off.

I'm going to either track down the fitting, the original hold off, or flare in a 3/16 fitting.

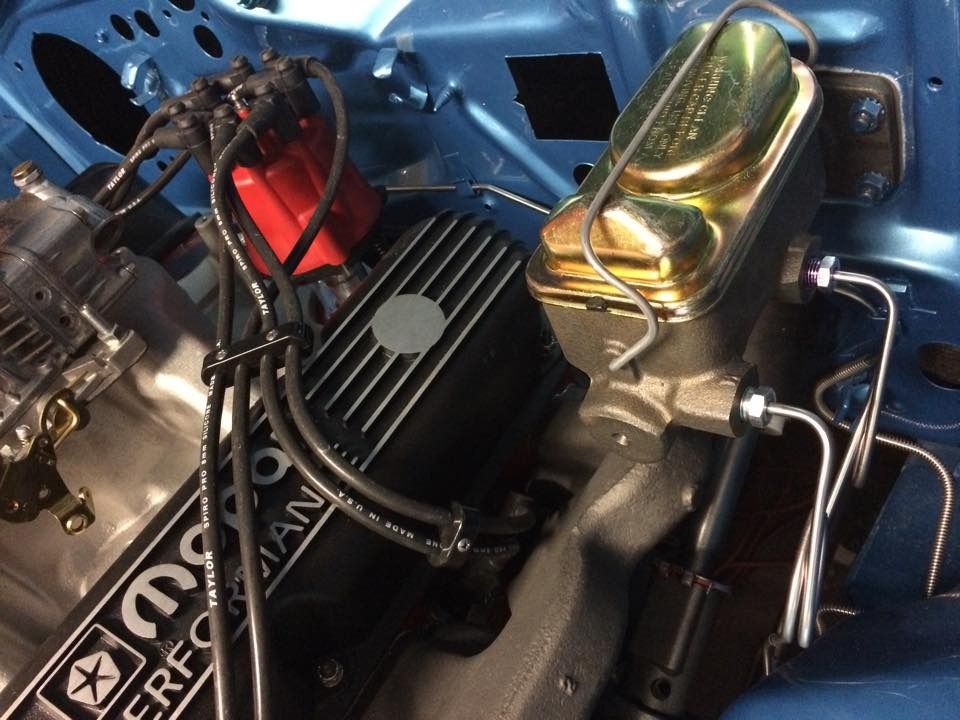

I ended up bending up another short section with 3/16 flare at both ends and using the combo valve with a coupling to Join the 2pc front to back section (ala AbodyJoe).

That being said I can also fit the adjustable prop valve at any time. AND I have the original short section with the 1/4 end if I want to go back to the factory standard block and hold off.

With he lines sorted out I plopped in the Master Cylinder.

After I was done with the brake lines and master I tackled the parking brake.

I went with Stainless steel parking brake cable from Inline tube. It went in nice and looks great next to the brake lines.

I still have to install the rear drum lines and connect the equalizer hardware but the hard part is done.