Valvebounce

Well-Known Member

yeah the bloke who made it reckoned it was a POS. hence why I hunted down an LD4B for my engine.

I will be running it in Hockenheim this year in August on a prepared track and I am very anxious to see how it will run.

yeah the bloke who made it reckoned it was a POS. hence why I hunted down an LD4B for my engine.

That intake looks cool in terms of workmanship. But if you're out to make power, the workmanship went into making the 4bbl attach. Not power. The runners are flat, the turn from plenum to runner is 90°, and the floor of the plenum is shallow and flat. 90° truns suck. Partially mixed fuel will come out of suspension and puddle in the plenum and the roof becomes a big turbulent mess where typically the best smoothest flow should be. I would say if your intention is to use it, I'd suggest epoxying the center of the floor and shaping it to turn the air better, adding pcs to help divide teh plenum as the ports are entered, add about 1.5" of height to the carb pad and put a much more generous radius on the transition from carb baseplate to port roof. The down side is, you do all that, you still only have a small cross section port. So a smaller engine will need to rev to use it and a larger engine will be out of breath early.

Cory: for sure you will need some staff there to prepare the car or measure tire pressure etc., won´t you? let me know if there´s a free seat in your dakota...:-D

greetz Michael

> I'm gutting-out the hyd. internals and installing a sleeve. AKA cheap mech roller lifters. I like the "deep skirt" design to pick-up side loads.I "may" make off-set push rod cups, for more serious builds. Anyone done this ? ateam.:read2:Not having the "A" pool of knwledege, to draw upon,(this forum), I purchased a pre magnum, roller cam 318, complete engine. This to power my 67' cuda coupe. Plans have change since then and this build is to propell a 2,400 lb., Jensen Healy roadster. I have magnum "eddy's" and performer rpm, dual plane, of which I believe will tend to limit power over 6k rpm. ? Steel crank and .02" "hyper" pistons, shot peened magnum rods with ARP. bolts. I'm thinkin this should hold more rpm. ? Edelbrock says this is "only" manifold for Magnum heads. Thoughts ? Thanks, ateam.:cheers:

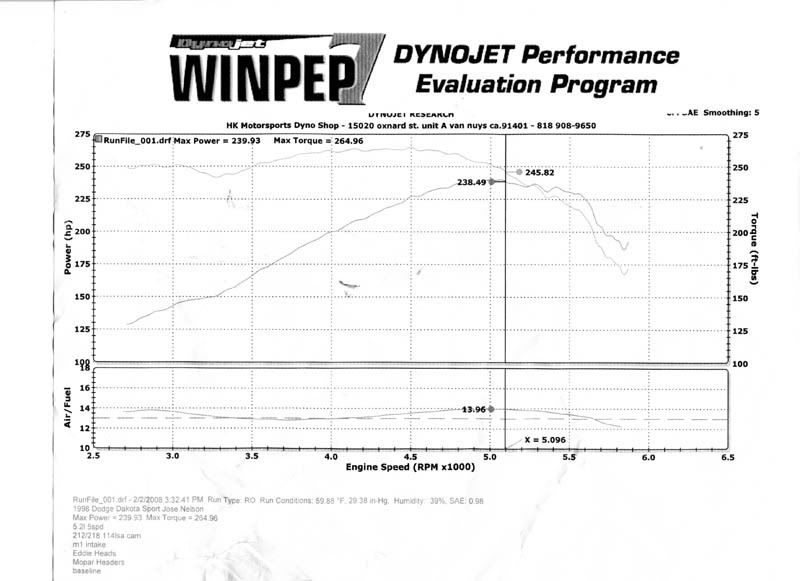

see i always had the idea if i were to go for a 318 build i would go for a magnum with fuel injection like your 97, to me thats not alot of work really for 340 hp at the crank, thats amazing and i think the fuel injection helps.. i never see a fuel injected 318 in any a body, there always torn down for a carb..My 318 build for my 97 dak ended up with 247 rwhp, 265 rwtq and a useless first gear!

That works out to around 340~ hp at the crank.

Mag heads ported

1.7 roller rockers

R/T cam 204/208 @.050" 114 centreline

M1 intake for magnum FI

ported TB

edelbrock shorty headers

flowmaster catback

Compression is around 9.1

I use the hypertech power programmer which I believe is limiting the engine a bit on the top end, but a fun drive nonetheless.

The "best" 318 build I've seen was my friends '70 Dart.

Bone Stock 1970 318 with a "very custom" exhaust . . . .

Twin Garret TO4 turbochargers and a cummins diesel intercooler - 12psi

He ran mid 11's all day with MT street slicks and 273 gears in the 8 1/4 and it was a RIOT on the street.

This might be a stupid question, but here it goes, been following this thread and something just doesn't seem rite to me and that is this. I have a 318 my brother-inlaw had in an Ply-Arrow he built back in the 80's back then he bought a set of 340 heads with a tri-angle valve job done on them and found that it didn't help at all actually hurt the engine, and have been told this ever since I got the motor, no it not in my car yet I can only wish for that rite now. So how can you guy's be talking about putting 360 heads on a 318 when 340 heads aren't a good idea, is it because you guy's have the head cut down? per say. I don't understand and my head hurts and feels like it's going to explode LOL.

Brad

To the 8-71 blower, ROCK ON! I would certainly beef up the bottom end though. Four bolt splayed caps with ARP studs and forged everything.

The build I am planing is:

KB flat tops(forged)

273 Forged crank

Unsure about rods, may reuse if it is cost effective.

XE284 cam, I know it is big.... I'll see how it runs then might step down if it is too much.

302 Heads for starters, I want to at least bump them up to 160 Ex valves. They will have a simple bowl blend as well as some port matching.

As for the intake, I will probably run a smaller port for now with the 302 heads(I have some decent ones), then most likely RPM air gap later down the road when I want more power and have better heads.

I want to run these rocker arms:

http://www.hughesengines.com/Index/...a2VyIEFybXMgJiBBY2Nlc3Nvcmllcw==&partid=22765

I really want to run 1.6 ratio but I am going to have to do for research first because that will be a ton of valve lift especially with an xe284 cam(544 to be exact)

Carb, maybe 670 street avenger, anybody think there would be much loss running the 770?

Transmission is a mild 904, going to get a 3000 stall. I have the lower first gear in it as well.

Rear is 8.75 with 3.55s

Looking for quick mid 13s... lol what do you guys think?