I cannot disagree.when that started we said cars like that had " The Blue Death"...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can't figure out this damned oil leak

- Thread starter RockinRobin

- Start date

-

Ironracer

Gearhead

That's Hillary-***! I've seen em, blue junk leaking oil everywhere! Gobs of crap mixed with oil! I've Never had no luck with that crapwhen that started we said cars like that had " The Blue Death"...

justinp61

Well-Known Member

- Joined

- May 15, 2009

- Messages

- 3,146

- Reaction score

- 4,153

when that started we said cars like that had " The Blue Death"...

I remember it well. My cousin put together a sbc for a pulling truck and used it everywhere. The engine made about three pulls before it ate it's self. When it was disassembled there was blue silicone everywhere, including the stopped up oil pick up. The truck owner was very unhappy.

To the OP, I'd swing by my local dealer and speak with one of their techs and get some advice on the seal install.

451 demon

Well-Known Member

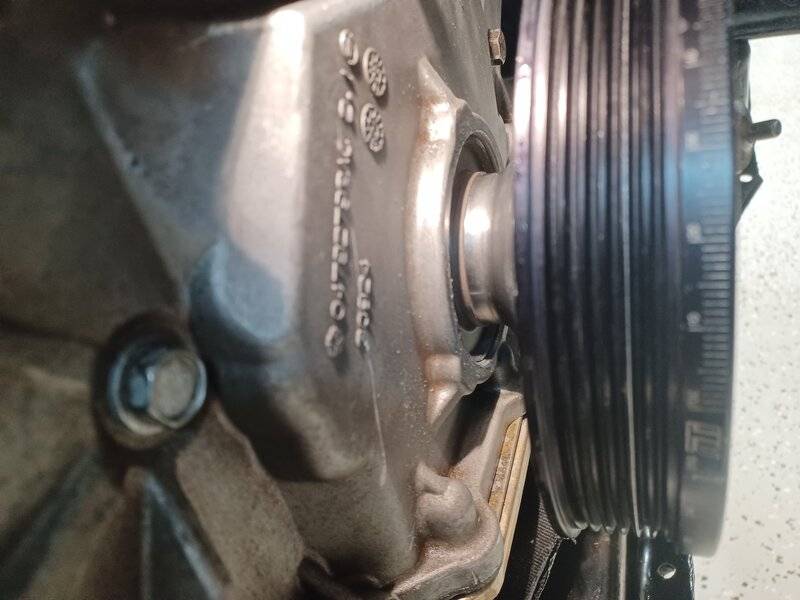

your installing it in backwards first picture is the back of the seal that goes toward the timing chain

451 demon

Well-Known Member

also install dry no rtv like everyone said

Yes and they leak from everywhere the blue is!when that started we said cars like that had " The Blue Death"...

mopar65

Well-Known Member

Over on the LX Fourm they was saying that the new mopar front crank seal, the side with the numbers/letters faces out. Also Robin i don't know if you already have this tool or even need it. But I found it while I was looking for info on the crank seal

The block has two dowels that the timing cover receives onto. Only thing I can think is if you loosen the pan completely to relieve the cover. Really splitting hairs at this point.

Hard to see the dowels. But, they're there!

mopar65

Well-Known Member

Here is a little more info about the seal installer.yup i see them.

as you said the sucking up of the oil pan is splitting hairs

I think that installer would be a help, especially in the car.

RockinRobin

Well-Known Member

Would probably work on a stock motor in the stock location. I have some complications to this situation:View attachment 1715988228

Hard to see the dowels. But, they're there!

1. I am not using motor mounts, I have a motor plate which is attached to the front cover. In order to get the front cover to move around, I would have to support the motor with a cherry picker and remove the motor plate, which is attached to the front cover very firmly with the grey mopar RTV. I don't think that sucker is ever coming off.

2. I do not have an OEM damper, it is an ATI super damper, the tube section that goes onto the crank sticks out further than the stock ones do.

3. Before this rebuild I never had an issue with this seal leaking. I think I may have installed it incorrectly the 1st time.

4. I have a friend who is a mechanic in the local dealership. He is going to come over and help me install it.

Understood. Your cover would still be dowled to the block? But, all things considered, you shouldn't be having issues. ATI should still work with stock seal and cover. Mine does. Hope you figure it out!Would probably work on a stock motor in the stock location. I have some complications to this situation:

1. I am not using motor mounts, I have a motor plate which is attached to the front cover. In order to get the front cover to move around, I would have to support the motor with a cherry picker and remove the motor plate, which is attached to the front cover very firmly with the grey mopar RTV. I don't think that sucker is ever coming off.

2. I do not have an OEM damper, it is an ATI super damper, the tube section that goes onto the crank sticks out further than the stock ones do.

3. Before this rebuild I never had an issue with this seal leaking. I think I may have installed it incorrectly the 1st time.

4. I have a friend who is a mechanic in the local dealership. He is going to come over and help me install it.

RockinRobin

Well-Known Member

I agree, as I recall those dowels fit into the front cover pretty tight, no wiggle room. We'll get it working. Like I said I had no trouble with it leaking before this build and it's the same damper and cover.Understood. Your cover would still be dowled to the block? But, all things considered, you shouldn't be having issues. ATI should still work with stock seal and cover. Mine does. Hope you figure it out!

451 demon

Well-Known Member

if you install the seal with the side in your last picture out. facing the dampner you shouldn't have any problem.if he works at a chrysler dealer he should have the tool like the holley tool so it should install easy

MopaR&D

Nerd Member

Check out the YouTube channel "Reignited - Cycle and Automotive", guy is a former Chrysler/Dodge/Jeep/Ram dealer technician with several G3 Hemi build videos and tons of "insider" tips and tricks. I imagine one of his assembly videos should show the correct orientation of the front crank seal.

RockinRobin

Well-Known Member

Thanks, I watched several of his videos and I got the info I was after. The protruding lip of the seal faces OUTWARD toward the back of the damper. I'll try to get this installed tonight, but you are supposed to wait at least 4 hours before running the motor to let the PTFE material form around the damper shaft.Check out the YouTube channel "Reignited - Cycle and Automotive", guy is a former Chrysler/Dodge/Jeep/Ram dealer technician with several G3 Hemi build videos and tons of "insider" tips and tricks. I imagine one of his assembly videos should show the correct orientation of the front crank seal.

MopaR&D

Nerd Member

Thanks, I watched several of his videos and I got the info I was after. The protruding lip of the seal faces OUTWARD toward the back of the damper. I'll try to get this installed tonight, but you are supposed to wait at least 4 hours before running the motor to let the PTFE material form around the damper shaft.

Awesome, glad I was able to help, at least indirectly! Lol

RockinRobin

Well-Known Member

Well we installed the new seal last night, with a little bit of black rtv on the back side. Let it sit all night and then fired it up this morning. No leaks!

I haven't been able to run it up to temp. yet as I am waiting on a new bottom radiator hose, but I am optimistic!

Here are some fuzzy shots of the seal, with the lip facing outward. It never got caught on any part of the damper going in, so no nicks. I sanded down the damper with #1000 sandpaper in case there were any burrs that might cause a problem. I should be able to take it to TNT in a week. If all goes well, next race is Oct. 8th.

I haven't been able to run it up to temp. yet as I am waiting on a new bottom radiator hose, but I am optimistic!

Here are some fuzzy shots of the seal, with the lip facing outward. It never got caught on any part of the damper going in, so no nicks. I sanded down the damper with #1000 sandpaper in case there were any burrs that might cause a problem. I should be able to take it to TNT in a week. If all goes well, next race is Oct. 8th.

mopowers

Well-Known Member

Wow, that's an odd looking seal. I probably would installed it backwards, like some here suggested. Glad you got it done correctly!

I likely would have too. How unusual.Wow, that's an odd looking seal. I probably would installed it backwards, like some here suggested. Glad you got it done correctly!

RockinRobin

Well-Known Member

Well, it's leaking again. Not enough to keep me off the track, but enough to where I have to wipe it off the K member after 2 or 3 passes.

Someone mentioned that if the block was align honed, the crank may be sitting a few thousands higher up in the block, but I would think the seal could compensate for that.

I'm not going to replace it again, just keep checking and wiping in between passes, it's just a few drops.

Someone mentioned that if the block was align honed, the crank may be sitting a few thousands higher up in the block, but I would think the seal could compensate for that.

I'm not going to replace it again, just keep checking and wiping in between passes, it's just a few drops.

I would think so too. But, stranger things happen.

A few thousands would be hard to see. and can't see the the seal not being able to seal that. But if the seal to crank was off enough to be the cause of the leak. It should be obvious to the eye.

Is this a boosted eng? is there crank case pressure? Is the thrust bearing loose cause the crank to go back and forth? Is it possible that the seal is rubbing on something, when its installed. Harmonic balancer rubbing on it, or the oil pump???

This is way off field but its it possible that you have a crank seal that was meant for a speedy leaves but didn't come in the box?

Is this a boosted eng? is there crank case pressure? Is the thrust bearing loose cause the crank to go back and forth? Is it possible that the seal is rubbing on something, when its installed. Harmonic balancer rubbing on it, or the oil pump???

This is way off field but its it possible that you have a crank seal that was meant for a speedy leaves but didn't come in the box?

-

Similar threads

- Replies

- 20

- Views

- 1K