PRH

Well-Known Member

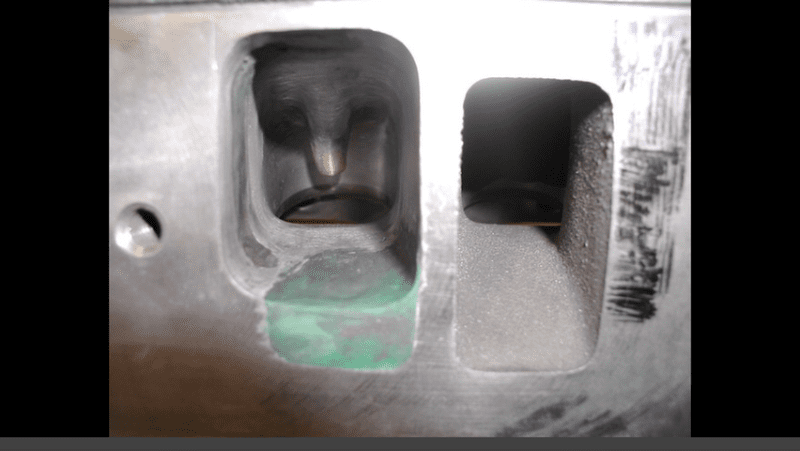

Nice job on these.

Looks like you filled in the spring pocket area as well.

The basic port work looks very similar to what was done to the stage 6’s used for the Moparts Enginemasters entry many moons ago. We didn’t do anything with the spring pockets though.

Here is a pic of them in progress:

Looks like you filled in the spring pocket area as well.

The basic port work looks very similar to what was done to the stage 6’s used for the Moparts Enginemasters entry many moons ago. We didn’t do anything with the spring pockets though.

Here is a pic of them in progress:

Last edited: