So.....just so I got this straight, if the starter was the problem and you KNEW IT, you'd pull the engine to change it?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

knock in engine

- Thread starter diymirage

- Start date

-

txstang84

Well-Known Member

Yeah I know about the thread...I commented in it as well. That being said, $1000 is $1000 that realistically could be used elsewhere in the car if needed...I read all the comments in there, and you were planning on slapping the same stock recon'd heads from your 360 on that 408. Not saying it wouldn't run well, but just seems a little wasteful to bump another 40 cubes out of it and not feed them appropriately, when you could upgrade something else on the car like brakes or suspension...but that's just my opinion.

txstang84

Well-Known Member

So.....just so I got this straight, if the starter was the problem and you KNEW IT, you'd pull the engine to change it?

I think I saw he said something about pulling the starter with those headers was as bad as pulling the engine...I guess his headers absolutely suck to pull out of the way.

diymirage

HP@idle > hondaHP@redline

So.....just so I got this straight, if the starter was the problem and you KNEW IT, you'd pull the engine to change it?

no, if I knew it was the starter I would pull the engine about 4 inches to get the driver side header off to get to the starter

however, I seriously doubt it is the starter (not doubting you or your insight) but the knock sounds to come from deeper within the engine and everytime I fire it up it gets worse

last time I ran it it actually sounded like there was no oil on it...like there was a squeak, squeak coming in with the knock knock

(the squeak squeak was the reason I pulled the valve covers to see if there was sufficient oil flow to the top end)

don't get me wrong, that starter will get thoroughly inspected as well once the motor is out and everything you mentioned is prone to failure will be looked at

NC Engine Builder

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 7,245

- Reaction score

- 12,242

Its in the bottom end, time to pull that puppy out and tear it down!

Its in the bottom end, time to pull that puppy out and tear it down!

x2!

I said that as soon as I heard the video. :clock:

If you keep running it, you will chernobyl it.... :cherry:

x2!

I said that as soon as I heard the video. :clock:

If you keep running it, you will chernobyl it.... :cherry:

Me 3 in post 34

Me 3 in post 34

It was actually post #35, but we're not going to argue about one post and one minute of time here... :banghead:

Your opinion has been noted. Thank you for noticing...

View attachment notice_the_notice.jpg

txstang84

Well-Known Member

magnumdart

There is a bad moon on the rise.

If the starter is that big of a deal to get at, when you get all done with the rest of it, why not just put in a new starter?

It was actually post #35, but we're not going to argue about one post and one minute of time here... :banghead:

Your opinion has been noted. Thank you for noticing...

View attachment 1714828563

You better revisit. I did post in #35 But I noted the bottom end in #34. If we're splitting hairs here

diymirage

HP@idle > hondaHP@redline

If the starter is that big of a deal to get at, when you get all done with the rest of it, why not just put in a new starter?

seriously considering it

that and new tie rod ends

no, if I knew it was the starter I would pull the engine about 4 inches to get the driver side header off to get to the starter

however, I seriously doubt it is the starter (not doubting you or your insight) but the knock sounds to come from deeper within the engine and everytime I fire it up it gets worse

last time I ran it it actually sounded like there was no oil on it...like there was a squeak, squeak coming in with the knock knock

(the squeak squeak was the reason I pulled the valve covers to see if there was sufficient oil flow to the top end)

don't get me wrong, that starter will get thoroughly inspected as well once the motor is out and everything you mentioned is prone to failure will be looked at

Oh I am not saying it is the starter......just threw it out there, because I have seen it. Sounded just like a bearing knock. So these are Dougs headers, right? Is the driver's side all one piece?

I ask because on my 65 I could remove one tube and have the starter out in 15 minutes.

diymirage

HP@idle > hondaHP@redline

yes, they are dougs headers

it would almost be quicker for me to drive from MI to GA to swap the starter on your 65 then it is to swap the starter on my 71 :banghead:

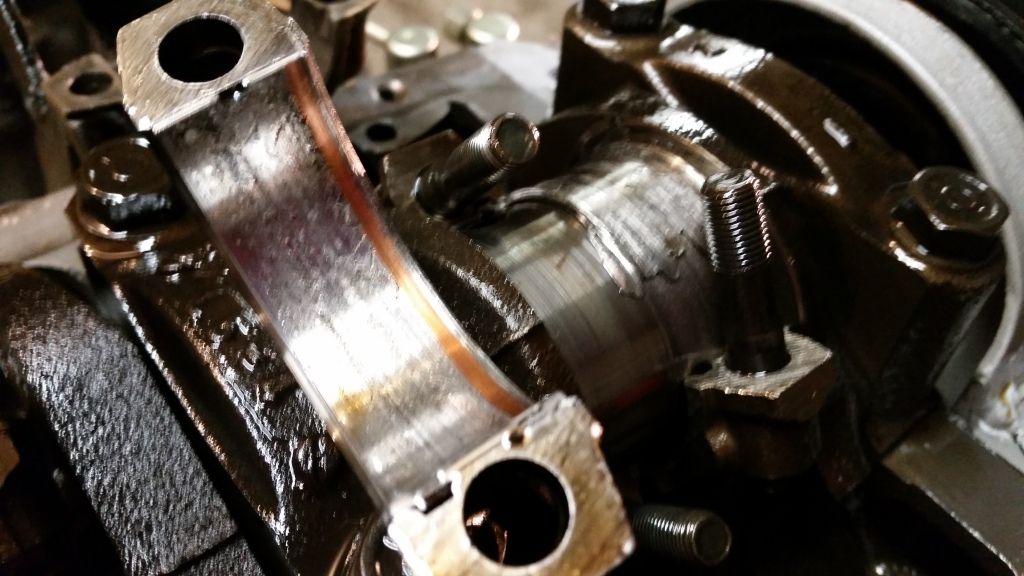

the starter and driver side header need to be installed at the same time, so the header needs to be completely disconnected, the steering linkage needs to be removed and the engine needs to be lifted up and tilted to the passenger side (so the driverside motor mount needs to be loosened as well)

yeah, i'd say at this point the motor is halfway out

as for as actual progress goes, the only things still hooked up are the transmission brace, the shifter linkage, the neutral/back up light switch, driver side header (only to the exhaust, already disconnected from the motor) and the starter

I should have her out tomorrow

it would almost be quicker for me to drive from MI to GA to swap the starter on your 65 then it is to swap the starter on my 71 :banghead:

the starter and driver side header need to be installed at the same time, so the header needs to be completely disconnected, the steering linkage needs to be removed and the engine needs to be lifted up and tilted to the passenger side (so the driverside motor mount needs to be loosened as well)

yeah, i'd say at this point the motor is halfway out

as for as actual progress goes, the only things still hooked up are the transmission brace, the shifter linkage, the neutral/back up light switch, driver side header (only to the exhaust, already disconnected from the motor) and the starter

I should have her out tomorrow

hangn0ut

Well-Known Member

I gotta say. You know when you got something sounding bad (knock knock) its not a wise move to continue to run it in an attempt to diagnosis it. It can quickly go from a bad bearing to a burned journel to a hole in the block. That's mo' money. And nobody wants to spend more than necessary.

66340SEDAN

FABO Member #3649

Knock knock......who's there?

hangn0ut

Well-Known Member

Dave... Dave's not here man...

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,608

- Reaction score

- 13,849

I heard that squeek-squeek one time. I pulled the car into the garage and went over it with a stethoscope. Engine was idling.Then it just quit. Pulled the pan and found #2 rod bearing was sticking to the crank and finally spun in the cap and locked it up.

Thats what happens when you run the crap out of your 340, while 2 qts low on oil.

Thats what happens when you run the crap out of your 340, while 2 qts low on oil.

txstang84

Well-Known Member

Dave... Dave's not here man...

No man, I'M Dave...dave? Yeah man-dave...Dave's not here...(cries)

hangn0ut

Well-Known Member

Classic. LOL! My name is Dave.

dart340h1973

Well-Known Member

the video is now working in the thread.

I would pull the oil pan and check the rod and main caps. That sounds like a lower end knock to me. I wouldn't take any chances on running it and breaking something without an inspection.

Or maybe the crank hitting on a windage tray or something.

Flex plate or torque converter bolts loose...

Just throwing out some ideas...

i had that with my 340. My problem was windage tray hitting crank throws. Just an idea.

diymirage

HP@idle > hondaHP@redline

I gotta say. You know when you got something sounding bad (knock knock) its not a wise move to continue to run it in an attempt to diagnosis it. It can quickly go from a bad bearing to a burned journel to a hole in the block. That's mo' money. And nobody wants to spend more than necessary.

the "runs" ive been referring to are short 30 second runs every time after I tried something someone suggested might have been the issue (removing the belts for instance to see if its the water pump)

from the moment I noticed the knock I've babied her home and she hasn't left the driveway since

I heard that squeek-squeek one time. I pulled the car into the garage and went over it with a stethoscope. Engine was idling.Then it just quit. Pulled the pan and found #2 rod bearing was sticking to the crank and finally spun in the cap and locked it up.

Thats what happens when you run the crap out of your 340, while 2 qts low on oil.

that is the plan no, get the engine out, pan off and inspect the rods

ive proven to myself that I don't know how to reseal the oil pan with the engine in the car so I knew if I pulled the pan I would have to pull the engine...even if it turned out NOT to need major surgery

the oil level has always been kept in check, though with the 8 quart pan, running 2 quarts low is still 6 quart

hangn0ut

Well-Known Member

30 Seconds @ 1000 rpm is 250 compression and power strokes. Ouch! I have diagniosed by running. That's how I learned. Just trying to help cause I've been there.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,608

- Reaction score

- 13,849

I'll wont say that I'll never confuse that squeek, for anything else. But it's a different squeek from anything else under the hood, and I hope I never hear it again!

-