weedburner

Well-Known Member

A clutch rating is just a quick/dirty way for the typical aftermarket clutch buying customer to feel assured that the clutch they buy isn't going to slip against the torque their engine is capable of. From the perspective of the aftermarket clutch manufacturer, if the clutch breaks something else downstream it's not their problem, at least the customer won't come back complaining about a weak clutch.

The T5 5spd serves as a good example. The T5 was an OE transmission for both GM and Ford, and the 2.95 gearset versions for both versions are nearly identical as far as case/gear strength. But the GM 2.95 V8 version has a reputation as being weak while it's pretty common to see Ford 2.95 V8 version running 10's on the dragstrip with slicks. The difference is the clutches that are commonly used with each version. GM T5 guys almost always go to the aftermarket and end up with around 2800-2900lbs of clamp from a 10.5" diaphragm, while the go-to clutch for the Ford T5 guys is the Ford Motorsport "King Cobra" 10.5" diaphragm which has 2124lbs of clamp.

Problem is the typical aftermarket clutch customer doesn't realize the ideal clutch is one that WILL slip. Not a clutch that slips against the maximum HP/TQ number that the engine is capable of, the clutch isn't going to see that static number at any point while the car is working its way thru the gears. The target should instead be a clutch that slips for a half second or so after a WOT shift into high gear.

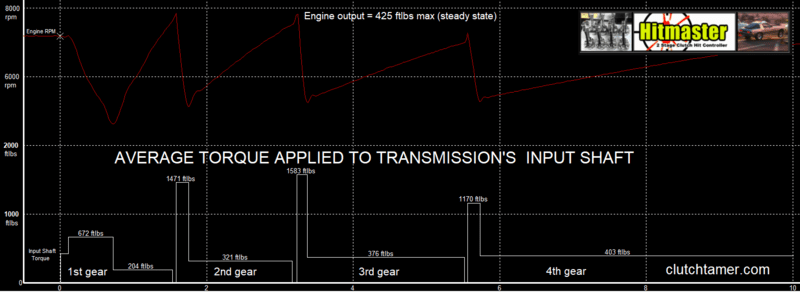

The Racepak graph below is of a dragstrip pass with an engine that puts out around 425ftlbs max WOT steady state. I added some averaged binary torque numbers to the lower part of the graph to reflect the calculated torque that the engine applied to the transmission's input shaft during the pass. Note how this 425ftlb engine put out way more than 425ftlbs when it is losing rpm, and much less than 425ftlbs when it is gaining rpm. At no time during this pass was this 425ftlb engine actually sending 425ftlbs to the transmission's input shaft, because at no time during this pass was the engine operating at a constant rpm. The engine was either losing or gaining rpm at every point after launch while it worked its way thru the gears. Note that during the climb in 1st gear, less than half of that engine's potential torque output was actually reaching the transmission's input shaft!

...you might ask- WHERE DID ALL THAT MISSING TORQUE GO???...

To wrap your head around this, it helps to think of the engine's rotating assy as a torque storage device. Everything spinning ahead of the transmission's input shaft is all basically one big energy storing flywheel. The reality is that some of this engine's torque was being absorbed by its rotating assy as it gained rpm, and then that absorbed/stored torque was returned as rpm was drawn out of that engine's rotating assy against WOT.

From there, it's important to understand that the rate that the clutch draws engine rpm down is what controls how that absorbed/stored torque gets applied to the transmission's input shaft. Using nice round numbers to make it easy to grasp the inverse relationship, let's say a rotating assy gains 2000rpm in 1 second while absorbing 200ftlbs of torque during the engine's climb to the 1/2 shift point...

...If the clutch then draws out the same 2000rpm over the same 1 second time period after the shift, 200ftlbs gets added back to the input shaft torque for 1 sec.

...If the clutch then draws out 2000rpm over 0.5sec (half the time), 400ftlbs of torque (double the torque) gets added to input shaft torque for that 0.50sec.

...If the clutch then draws out 2000rpm over 0.25sec, 800ftlbs of torque gets added to input shaft torque for that 0.25sec.

All three above examples of discharge rate release the same quantity of energy. Give the car 200ftlb "boost" for 1sec (200 x 1 = 200), vs a 400ftlb boost for .5sec (400 x .5 = 200), vs an 800ftlb boost for .25sec (800 x .25 = 200), it's all basically the same amount of boost available from 2000rpm's worth of returning energy.

When you go beyond daily driving and move to the track, drawing that stored energy out too fast can cause other problems downstream. The initial problems are likely to be either traction or finding weak links in your drivetrain. If the tires go up in smoke, the typical solution is to buy better tires. If the problem is wheelhop, new bushings/shocks/chassis components. If the driveshaft or u-joints fail, bigger/stronger parts. If the transmission breaks, stronger trans. Break rear gears/diff/axles, spend another pile of money on a rear upgrade. But even after you get all those things sorted out, you will find your combination is still not performing to its potential, as now the engine bogs. When the root cause of the cascading problems is an overkill clutch that draws too much torque from the rotating assy, addressing that problem first could save you from making a lot of un-necessary upgrades.

Given that a 2000rpm discharge releases the same basic quantity of energy regardless of how fast you lose the rpm, you have to ask yourself how big of a torque spike can your drivetrain/chassis efficiently handle? Are the tires going to be shocked into excessive wheelspin and waste a large portion of the returned energy? Is it going to break something? Would it be better to use a clutch that draws 400ftlbs of stored energy over 0.50sec rather than one that draws 800ftlbs over 0.25sec?

The clutch's stored energy draw rate is every bit as important to the performance of a stick shift car as choosing the right converter for an automatic car. When you just bolt in a typical non-adjustable clutch, you are pretty much locked into whatever rate it might pull your engine down against WOT. There is no advantage to buying a clutch that pulls 800ftlbs out of a 425ftlb engine's rotating assy. Don't buy a clutch with plans to "grow into it", it is far better to pick one that's the best match for your engine and use. Not a situation where too much is just right. Excess torque capacity not only increases the clutch's potential to inflict damage on your drivetrain, but it will also slow you down at the dragstrip.

All that said, I make devices that can momentarily soften the hit of any clutch. This enables your existing clutch to initially hit like a much softer unit without giving up any of it's holding power. A diaphragm clutch controlled by one of my Hitmaster units recently took home the $10k winner's share in the stick shift class at the '22 World Cup Finals!!!

Grant

The T5 5spd serves as a good example. The T5 was an OE transmission for both GM and Ford, and the 2.95 gearset versions for both versions are nearly identical as far as case/gear strength. But the GM 2.95 V8 version has a reputation as being weak while it's pretty common to see Ford 2.95 V8 version running 10's on the dragstrip with slicks. The difference is the clutches that are commonly used with each version. GM T5 guys almost always go to the aftermarket and end up with around 2800-2900lbs of clamp from a 10.5" diaphragm, while the go-to clutch for the Ford T5 guys is the Ford Motorsport "King Cobra" 10.5" diaphragm which has 2124lbs of clamp.

Problem is the typical aftermarket clutch customer doesn't realize the ideal clutch is one that WILL slip. Not a clutch that slips against the maximum HP/TQ number that the engine is capable of, the clutch isn't going to see that static number at any point while the car is working its way thru the gears. The target should instead be a clutch that slips for a half second or so after a WOT shift into high gear.

The Racepak graph below is of a dragstrip pass with an engine that puts out around 425ftlbs max WOT steady state. I added some averaged binary torque numbers to the lower part of the graph to reflect the calculated torque that the engine applied to the transmission's input shaft during the pass. Note how this 425ftlb engine put out way more than 425ftlbs when it is losing rpm, and much less than 425ftlbs when it is gaining rpm. At no time during this pass was this 425ftlb engine actually sending 425ftlbs to the transmission's input shaft, because at no time during this pass was the engine operating at a constant rpm. The engine was either losing or gaining rpm at every point after launch while it worked its way thru the gears. Note that during the climb in 1st gear, less than half of that engine's potential torque output was actually reaching the transmission's input shaft!

...you might ask- WHERE DID ALL THAT MISSING TORQUE GO???...

To wrap your head around this, it helps to think of the engine's rotating assy as a torque storage device. Everything spinning ahead of the transmission's input shaft is all basically one big energy storing flywheel. The reality is that some of this engine's torque was being absorbed by its rotating assy as it gained rpm, and then that absorbed/stored torque was returned as rpm was drawn out of that engine's rotating assy against WOT.

From there, it's important to understand that the rate that the clutch draws engine rpm down is what controls how that absorbed/stored torque gets applied to the transmission's input shaft. Using nice round numbers to make it easy to grasp the inverse relationship, let's say a rotating assy gains 2000rpm in 1 second while absorbing 200ftlbs of torque during the engine's climb to the 1/2 shift point...

...If the clutch then draws out the same 2000rpm over the same 1 second time period after the shift, 200ftlbs gets added back to the input shaft torque for 1 sec.

...If the clutch then draws out 2000rpm over 0.5sec (half the time), 400ftlbs of torque (double the torque) gets added to input shaft torque for that 0.50sec.

...If the clutch then draws out 2000rpm over 0.25sec, 800ftlbs of torque gets added to input shaft torque for that 0.25sec.

All three above examples of discharge rate release the same quantity of energy. Give the car 200ftlb "boost" for 1sec (200 x 1 = 200), vs a 400ftlb boost for .5sec (400 x .5 = 200), vs an 800ftlb boost for .25sec (800 x .25 = 200), it's all basically the same amount of boost available from 2000rpm's worth of returning energy.

When you go beyond daily driving and move to the track, drawing that stored energy out too fast can cause other problems downstream. The initial problems are likely to be either traction or finding weak links in your drivetrain. If the tires go up in smoke, the typical solution is to buy better tires. If the problem is wheelhop, new bushings/shocks/chassis components. If the driveshaft or u-joints fail, bigger/stronger parts. If the transmission breaks, stronger trans. Break rear gears/diff/axles, spend another pile of money on a rear upgrade. But even after you get all those things sorted out, you will find your combination is still not performing to its potential, as now the engine bogs. When the root cause of the cascading problems is an overkill clutch that draws too much torque from the rotating assy, addressing that problem first could save you from making a lot of un-necessary upgrades.

Given that a 2000rpm discharge releases the same basic quantity of energy regardless of how fast you lose the rpm, you have to ask yourself how big of a torque spike can your drivetrain/chassis efficiently handle? Are the tires going to be shocked into excessive wheelspin and waste a large portion of the returned energy? Is it going to break something? Would it be better to use a clutch that draws 400ftlbs of stored energy over 0.50sec rather than one that draws 800ftlbs over 0.25sec?

The clutch's stored energy draw rate is every bit as important to the performance of a stick shift car as choosing the right converter for an automatic car. When you just bolt in a typical non-adjustable clutch, you are pretty much locked into whatever rate it might pull your engine down against WOT. There is no advantage to buying a clutch that pulls 800ftlbs out of a 425ftlb engine's rotating assy. Don't buy a clutch with plans to "grow into it", it is far better to pick one that's the best match for your engine and use. Not a situation where too much is just right. Excess torque capacity not only increases the clutch's potential to inflict damage on your drivetrain, but it will also slow you down at the dragstrip.

All that said, I make devices that can momentarily soften the hit of any clutch. This enables your existing clutch to initially hit like a much softer unit without giving up any of it's holding power. A diaphragm clutch controlled by one of my Hitmaster units recently took home the $10k winner's share in the stick shift class at the '22 World Cup Finals!!!

Grant