I guess we are pretty average together. 423ci/360, 950 4bbl, Victor intake, ProComp heads 280cfm @ .500, 290cfm @ .600, custom solid roller, .600" net lift measured at retainer with the engine fully assembled. 561 lb-ft and one pull at 601 hp. Everything else at 593-596 hp.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Missed on this combo?

- Thread starter Ironmike

- Start date

-

RAMM

Well-Known Member

I guess we are pretty average together. 423ci/360, 950 4bbl, Victor intake, ProComp heads 280cfm @ .500, 290cfm @ .600, custom solid roller, .600" net lift measured at retainer with the engine fully assembled. 561 lb-ft and one pull at 601 hp. Everything else at 593-596 hp.

Love you Jim because you're honest. Sorry for the cussing but when I get real revved up about something I am 100% confident in-it happens. Cracking an honest 600HP is VERY difficult if not impossible. I know this is getting off track here but this engine is pretty decent as it is. It is soft down low which tells me retarding the cam ain't gonna help Jack and the engine will never recover up top--it doesn't work that way hardly ever. I can tell how good a dyno run is going to be as soon as that initial torque number rolls in. I abort many runs as it is a waste of fuel/time and motor if it doesn't look good right away. J.Rob

o1heavy

1974 dart sport

These standard port heads are just that

if your looking for some decent power

They can deliver

But to be "competitive" the push rod pinch has to be addressed

And when it's all said and done it's not that much more money to just that

if your looking for some decent power

They can deliver

But to be "competitive" the push rod pinch has to be addressed

And when it's all said and done it's not that much more money to just that

Love you Jim because you're honest. Sorry for the cussing but when I get real revved up about something I am 100% confident in-it happens. Cracking an honest 600HP is VERY difficult if not impossible. I know this is getting off track here but this engine is pretty decent as it is. It is soft down low which tells me retarding the cam ain't gonna help Jack and the engine will never recover up top--it doesn't work that way hardly ever. I can tell how good a dyno run is going to be as soon as that initial torque number rolls in. I abort many runs as it is a waste of fuel/time and motor if it doesn't look good right away. J.Rob

This will probably lend more credence to your cylinder head theory. My cam isn't that much different from what Mike is running..........

Mike...................................old Jim

.668/.668.........................638/.645

259/265...........................258/260

108 LSA/104 ICL........110 LSA/106 ICL

Yet the dyno results are markedly different. You can't race dynos, but this is my dyno, and we do calibrate it. This is the one and only pull we started at 2,500 rpm.

RPM...........TQ/HP...............TQ/HP

2500..........NA/NA............371/177

3000..........NA/NA............454/259

3500..........NA/NA............474/316

4000........419/319..........469/357

4500........497/426..........537/460

5000........523/498..........551/525

5500........506/530..........542/568

6000........483/551..........514/587

6100........480/557..........510/592

6200........474/559..........501/591

6300........467/560..........491/589

6400........457/557..........484/590

6500........448/554............NA/NA

I agree that Mike's engine is pretty good, and I think probably better than most. It could be even better.

RAMM

Well-Known Member

This will probably lend more credence to your cylinder head theory. My cam isn't that much different from what Mike is running..........

Mike...................................old Jim

.668/.668.........................638/.645

259/265...........................258/260

108 LSA/104 ICL........110 LSA/106 ICL

Yet the dyno results are markedly different. You can't race dynos, but this is my dyno, and we do calibrate it. This is the one and only pull we started at 2,500 rpm.

RPM...........TQ/HP...............TQ/HP

2500..........NA/NA............371/177

3000..........NA/NA............454/259

3500..........NA/NA............474/316

4000........419/319..........469/357

4500........497/426..........537/460

5000........523/498..........551/525

5500........506/530..........542/568

6000........483/551..........514/587

6100........480/557..........510/592

6200........474/559..........501/591

6300........467/560..........491/589

6400........457/557..........484/590

6500........448/554............NA/NA

I agree that Mike's engine is pretty good, and I think probably better than most. It could be even better.

This ^^^^^^is right in line with what I have seen. I know this is off track but I haven't seen 700 hp with a pump gas smallblock with the baddest W9's.

If I built this engine I would only be addressing the softish power down low-the HP is fine. A 3" collector 18"

This will probably lend more credence to your cylinder head theory. My cam isn't that much different from what Mike is running..........

Mike...................................old Jim

.668/.668.........................638/.645

259/265...........................258/260

108 LSA/104 ICL........110 LSA/106 ICL

Yet the dyno results are markedly different. You can't race dynos, but this is my dyno, and we do calibrate it. This is the one and only pull we started at 2,500 rpm.

RPM...........TQ/HP...............TQ/HP

2500..........NA/NA............371/177

3000..........NA/NA............454/259

3500..........NA/NA............474/316

4000........419/319..........469/357

4500........497/426..........537/460

5000........523/498..........551/525

5500........506/530..........542/568

6000........483/551..........514/587

6100........480/557..........510/592

6200........474/559..........501/591

6300........467/560..........491/589

6400........457/557..........484/590

6500........448/554............NA/NA

I agree that Mike's engine is pretty good, and I think probably better than most. It could be even better.

If I built this engine I would be addressing the power down low-the HP is fine. My first move and probably last would be a 3" x 18" long collector. It ain't the carb, cam, LSA or whatever. The heads are the limit and probably turbulent or like the dyno guy said the exhaust ports probably move more into the intake manifold than out the exhaust-that is why he hates them. Put a small *** header with a long collector with a port to header mismatch-yes mismatch and watch the bottom end tq swell. J.Rob

RAMM

Well-Known Member

For the record I have never seen a 108 LSA work yet--hate them. I'd rather a 106 or a 110-112 but if you're gonna go 106 then go tighter--104. Don't know exactly why but 108 does nothing well. Hate 'em.J.Rob

yellow rose

Overnight Sensation

Mike , I know you are frustrated because I'm frustrated just reading and reliving my own experiences.

That cam is wrong, but until you fix/change the heads NO cam will give you what you want. I don't even care if you're chasing a dyno number. That engine as it is will SUCK if you don't treat it like a 340 (5000 stall/4.56 gear type stuff) You need to send your heads to a PRO like Vic Bloomer or Brett Miller and then you can stick almost ANY cam in and watch those dyno numbers grow AND the car will respond in kind. J.Rob

I agree. I can say I've never seen a Hughes port job. So maybe they ARE that shitty. I drives me batshit crazy when I can't test the head myself and all I get is the numbers. The numbers tell you about 25% of what you want to know.

IM also said this engine guy hated the exhaust port. I'd like to know why. Let's face it...the OE exhaust port is **** on a shingle in its best configuration. I'm still waiting for the weather to clear, but I'd like to the intake and exhaust both with 50* seats. When a head is struggling the steeper seats seem to help because it changes the air flow pattern around the valve, which helps with high air speed.

I believe you can get to where you want if you help the heads with cam timing. If you had well prepped W-2's you might get away with only 255 at .050 and still get the same RPM peak. And if the heads were real good, you'd see a 110-111 LSA. But they better be good heads.

I'm with RAMM. Reading this stuff makes my blood boil. I know where I've went off the reservation, and how much it costs. It's absolutely frustrating.

BTW, when checking valve lift on my W-2 engine, which had 300 on the seat and much more pushrod geometry issues than you have, was dead spot on with Norris rocker arms. They designed the rocker to compensate for the geometry. I know Jesel does this as well. B3 gave pretty close numbers about how far lift gets off. The rocker are can be made to get the ratio way closer under full spring load if they want to.

The Norris rockers were 1.6 and when measured with soft springs they were about 1.72 and with full spring load they were exactly 1.6.

Ironmike

Well-Known Member

hey man, sorry to bring back bad memories but sure as **** are glad your helping me here.....Mike , I know you are frustrated because I'm frustrated just reading and reliving my own experiences.

That cam is wrong, but until you fix/change the heads NO cam will give you what you want. I don't even care if you're chasing a dyno number. That engine as it is will SUCK if you don't treat it like a 340 (5000 stall/4.56 gear type stuff) You need to send your heads to a PRO like Vic Bloomer or Brett Miller and then you can stick almost ANY cam in and watch those dyno numbers grow AND the car will respond in kind. J.Rob

I'm not really chasing a number. Not a race car. It's a street/strip Demon 4 speed 4:10 gears. Its 3090lbs with me in it. It gets run hard on the street. Very hard. Id have been happy with the original 560 HP IF the friggin thing made some torque down low.

I had a cylinder head guy 5 miles away who flowed some iron heads for me year before last. All he did for 40 years was heads. Nice guy too. Guess what? Retired. If anyone knows of a flow bench anywhere near Pittsburgh, please chime in!

I agree with pretty much what everybody is saying. I just don't believe a different cam will fix it completely. I WISH, but wonder how much it might help.

Can heads that have been ...lets say ported badly, be corrected without welding and huge expense?

I have some pics of them before the install, what about if I got some really good pics of the exhaust ports?

yellow rose

Overnight Sensation

hey man, sorry to bring back bad memories but sure as **** are glad your helping me here.....

I'm not really chasing a number. Not a race car. It's a street/strip Demon 4 speed 4:10 gears. Its 3090lbs with me in it. It gets run hard on the street. Very hard. Id have been happy with the original 560 HP IF the friggin thing made some torque down low.

I had a cylinder head guy 5 miles away who flowed some iron heads for me year before last. All he did for 40 years was heads. Nice guy too. Guess what? Retired. If anyone knows of a flow bench anywhere near Pittsburgh, please chime in!

I agree with pretty much what everybody is saying. I just don't believe a different cam will fix it completely. I WISH, but wonder how much it might help.

Can heads that have been ...lets say ported badly, be corrected without welding and huge expense?

I have some pics of them before the install, what about if I got some really good pics of the exhaust ports?

If you want to pay the freight I'll flow them for FREE on a Flow Data 700 bench. All you have to do is pay the freight.

PM me if interested. Hell, I'd even tell you if I think I can fix them. Or if they are not worth fixing.

yellow rose

Overnight Sensation

Yellow Rose made a generous offer, but if you need someone near Pittsburgh, a small block Mopar guy, John Cadamore, is close by. He goes by pittsburghracer on the Moparts forum.

That would certainly be closer for him.

My offer still stands though.

someone who has ported/flowed there fair share of head can tell you just as much about them head with his eyes and ears as the Numbers!

There was a well known head port that posted on speedtalk, that showed an example of two different ports that's he created, that flowed the same CFM had the same CC port volume, same head. on the dyno one set of heads made (i don't remember the exact #) like 100+ more HP and a bunch more tq then the other. Flow number are just that, there a tool.

For someone buying a cookie cutter ported head...........that's all you can do to compare, is the flow number.

Ow and YES would love to see them exh ports in some good photos!!!!!!

There was a well known head port that posted on speedtalk, that showed an example of two different ports that's he created, that flowed the same CFM had the same CC port volume, same head. on the dyno one set of heads made (i don't remember the exact #) like 100+ more HP and a bunch more tq then the other. Flow number are just that, there a tool.

For someone buying a cookie cutter ported head...........that's all you can do to compare, is the flow number.

Ow and YES would love to see them exh ports in some good photos!!!!!!

yellow rose

Overnight Sensation

Yellow Rose made a generous offer, but if you need someone near Pittsburgh, a small block Mopar guy, John Cadamore, is close by. He goes by pittsburghracer on the Moparts forum.

I was trying to think of his name but I just couldn't recall it.

Mike, Another one is Cook&Kell's racing engines Chester, WV Take rt. 30 right past the airport. Its about 30 min. From Pitt International.

Ironmike

Well-Known Member

Man, you guys are great! I'm learning so much just from this post....and YR, I cant thank you enough for the offer. I may even take you up on it. I have some things here to address. Going to be a bit long and picture heavy, but i'll try to be straight to the point.

1. the issue of my lift at the valve. Well if you remember I came up with .626 at the retainer. Supposed to be .668 per cam card. I know about geometry loss and all that BUT....got home from work and decided to measure the lift on my "in car" engine.

The cam is a Lunati showing .640/.640 on the card. You can see in the 2 pics I came up with .623 and .618. Add the 0.14 lash and you come up with .637 and .633. You can see the indicator for yourself. Remember you're reading it backwards from zero. I did it 2 different ways. So......the fact is my Lunati with .400 lobe lift and 1.6 rockers came up very close to the card specs for "valve lift"(.640). Within .007.

And the Bullet with .4176 lobe lift and 1.6 rockers came way short at .626. .042 thousands short. Thats a lot of lift to lose compared to .007. So either cam is off or rockers aren't right. Which is off is anyone's guess. But something ain't right.

Next issue, my dyno guy calls me AT WORK today, on Sunday cause it's buggin' him too. He asked if I remember which pipes we had running out the wall. He said we might have used some 8 inchers that he was using to dyno some blown alcohol thing earlier in the week. He usually runs a 4 inch pipe from the header through the wall. Said if we did, that may have a LOT to do with the numbers. Especially torque.

I happen to take a couple pics that day and sure as hell those pipes don't look like 4 inchers coming off the header. Can that really make much difference?

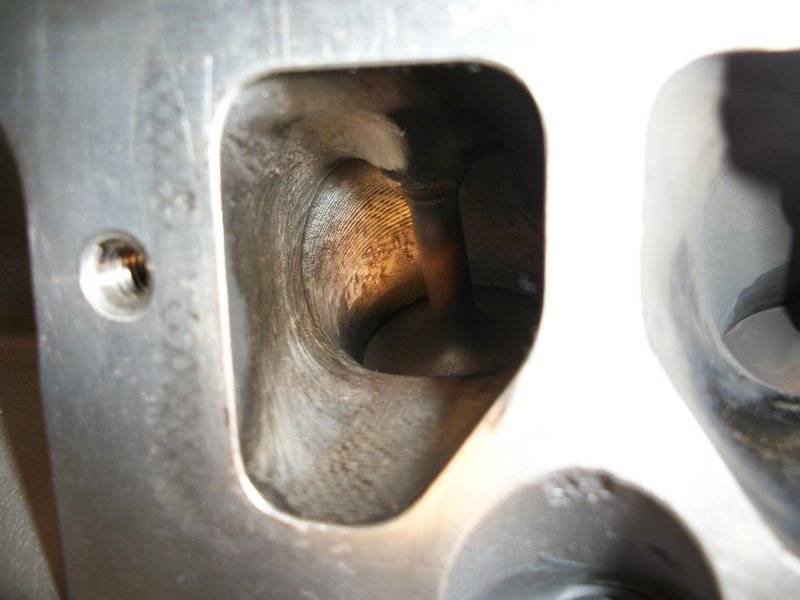

Last, I posted a couple crappy pics of an exhaust port. Don't know if you guys can evaluate the porting or not. Hard to get a good view with my camera.

Well, thats all I got for now. Don't know whether to call Hughes or Bullet tomorrow. Personally from my measuring at the pushrod......I am pretty sure the cam is not right.

Maybe all I need is a proper cam and smaller pipes on my next trip to the dyno?

1. the issue of my lift at the valve. Well if you remember I came up with .626 at the retainer. Supposed to be .668 per cam card. I know about geometry loss and all that BUT....got home from work and decided to measure the lift on my "in car" engine.

The cam is a Lunati showing .640/.640 on the card. You can see in the 2 pics I came up with .623 and .618. Add the 0.14 lash and you come up with .637 and .633. You can see the indicator for yourself. Remember you're reading it backwards from zero. I did it 2 different ways. So......the fact is my Lunati with .400 lobe lift and 1.6 rockers came up very close to the card specs for "valve lift"(.640). Within .007.

And the Bullet with .4176 lobe lift and 1.6 rockers came way short at .626. .042 thousands short. Thats a lot of lift to lose compared to .007. So either cam is off or rockers aren't right. Which is off is anyone's guess. But something ain't right.

Next issue, my dyno guy calls me AT WORK today, on Sunday cause it's buggin' him too. He asked if I remember which pipes we had running out the wall. He said we might have used some 8 inchers that he was using to dyno some blown alcohol thing earlier in the week. He usually runs a 4 inch pipe from the header through the wall. Said if we did, that may have a LOT to do with the numbers. Especially torque.

I happen to take a couple pics that day and sure as hell those pipes don't look like 4 inchers coming off the header. Can that really make much difference?

Last, I posted a couple crappy pics of an exhaust port. Don't know if you guys can evaluate the porting or not. Hard to get a good view with my camera.

Well, thats all I got for now. Don't know whether to call Hughes or Bullet tomorrow. Personally from my measuring at the pushrod......I am pretty sure the cam is not right.

Maybe all I need is a proper cam and smaller pipes on my next trip to the dyno?

yellow rose

Overnight Sensation

Man, you guys are great! I'm learning so much just from this post....and YR, I cant thank you enough for the offer. I may even take you up on it. I have some things here to address. Going to be a bit long and picture heavy, but i'll try to be straight to the point.

1. the issue of my lift at the valve. Well if you remember I came up with .626 at the retainer. Supposed to be .668 per cam card. I know about geometry loss and all that BUT....got home from work and decided to measure the lift on my "in car" engine.

The cam is a Lunati showing .640/.640 on the card. You can see in the 2 pics I came up with .623 and .618. Add the 0.14 lash and you come up with .637 and .633. You can see the indicator for yourself. Remember you're reading it backwards from zero. I did it 2 different ways. So......the fact is my Lunati with .400 lobe lift and 1.6 rockers came up very close to the card specs for "valve lift"(.640). Within .007.

And the Bullet with .4176 lobe lift and 1.6 rockers came way short at .626. .042 thousands short. Thats a lot of lift to lose compared to .007. So either cam is off or rockers aren't right. Which is off is anyone's guess. But something ain't right.

Next issue, my dyno guy calls me AT WORK today, on Sunday cause it's buggin' him too. He asked if I remember which pipes we had running out the wall. He said we might have used some 8 inchers that he was using to dyno some blown alcohol thing earlier in the week. He usually runs a 4 inch pipe from the header through the wall. Said if we did, that may have a LOT to do with the numbers. Especially torque.

I happen to take a couple pics that day and sure as hell those pipes don't look like 4 inchers coming off the header. Can that really make much difference?

Last, I posted a couple crappy pics of an exhaust port. Don't know if you guys can evaluate the porting or not. Hard to get a good view with my camera.

Well, thats all I got for now. Don't know whether to call Hughes or Bullet tomorrow. Personally from my measuring at the pushrod......I am pretty sure the cam is not right.

Maybe all I need is a proper cam and smaller pipes on my next trip to the dyno?View attachment 1715027435 View attachment 1715027436 View attachment 1715027437 View attachment 1715027438 View attachment 1715027439 View attachment 1715027440

I hate that port as much as the next guy but it's better than the OEM port. I can't see the short turn. Maybe it's not finished correctly but I can't see that from the picture.

If you feel like it, you can take the rockers off and mount you dial indicator as secure as you can get it. Take an old pushrod and cut it off as short as possible and still get the indicator in line with the lifter. Then very carefully just measure the lobe lift. You already know what it is at the valve. The trick is keeping everything in line. I like the indicator to just sit in the end of the cut pushrod. It keeps things stable.

I'm no betting man but, I'd bet a bunch the error is in the rocker. In 1987 I ordered a crower cam. It was a catalog grind but it was close enough except for LSA, so we had them move the LSA from 110 IIRC to 107.

When the cam showed up in January of 88 the numbers on the card weren't close to what the catalog called out. So I called crower and they said moving the LSA that far made the events change a bit. So I gained some lift on the intake, lost a bit on the exhaust and the at .050 numbers had a bit more split than I wanted.

When I installed the cam, nothing on the card matched the cam. Not one intake lobe matched another. Crower blamed the rockers, but I checked stuff at the lobe. Then they said my lifter bank angles were poo-poo. Bad thing was, the bores were lifter trued and bushed. I think that engine only made 625 or so at 7800 so I was disappointed.

BTW, I have a used, true Harold Brookshire UltraDyne roller cam in the for sale section. Tell you what lol do. I will send you the cam. You test it. If it makes power, you owe me the shipping. If not, I'll pay you to have it shipped back. I posted numbers in the for sale section but I found the cam card and I don't think I have all the numbers correct there.

The numbers are:

278/281 .050

.640/.640 I lashed it at .022 hot

106 LSA goes in at 100

If you want to try it PM me your info and I'll send it out tomorrow. You could at least see if you are going in the right direction, relative to duration and LSA.

Last edited:

Healthy *** cam, dang!

RAMM

Well-Known Member

Yellow Rose made a generous offer, but if you need someone near Pittsburgh, a small block Mopar guy, John Cadamore, is close by. He goes by pittsburghracer on the Moparts forum.

John is sharp and realistic, he would be a great Third party. J.Rob

nm9stheham

Well-Known Member

Good detective work on the valve lift, Mike. I think you have found part of the problem. Move your indicator right down onto the top of the lifter as close as you can get, (as YR said) and see if your get the full lobe lift spec; that will settle that issue.

And note again that Bullet looks to spec the valve lift by simply multiplying the lobe lift times the rocker ratio, so once the Mopar system lash and geometry errors are into the picture, then it will never get to that advertised lift, even with true 1.6 rockers.

And note again that Bullet looks to spec the valve lift by simply multiplying the lobe lift times the rocker ratio, so once the Mopar system lash and geometry errors are into the picture, then it will never get to that advertised lift, even with true 1.6 rockers.

nm9stheham

Well-Known Member

It sure will. I once welded some 18" long, 3" diameter collectors in place of some 9", 2.75" diameter collectors, and picked up some very noticeable low end torque. (That was waaaay before dynos were common, and I was poor, so sorry, no numbers!) All of this effect has been documented and known for 60-70 years.... and I think RAMM mentioned this earlier.Next issue, my dyno guy calls me AT WORK today, on Sunday cause it's buggin' him too. He asked if I remember which pipes we had running out the wall. He said we might have used some 8 inchers that he was using to dyno some blown alcohol thing earlier in the week. He usually runs a 4 inch pipe from the header through the wall. Said if we did, that may have a LOT to do with the numbers. Especially torque.

I happen to take a couple pics that day and sure as hell those pipes don't look like 4 inchers coming off the header. Can that really make much difference?

There is a program out there Called "Pipe Max" that will predict the best header diameter/length and collector extension diameter/length.

It works and it's like $40

Getting all these lengths right, keep the exh pulling on each cyl that is in the potential reversion point.

This is not going to fix your problems but, it will help!

It works and it's like $40

Getting all these lengths right, keep the exh pulling on each cyl that is in the potential reversion point.

This is not going to fix your problems but, it will help!

Thanks for the exh port pic's!

As YR said, you can't really see the short side turn...........but from what i can see, it seam to come of sharp!?!

Take you finger and fill how the floor turns. it should be a fairly consistent radius from the last seat cut to where you can see the floor in the picture.

It would be interesting to see what the ratio is between intake and exhaust ports (CC Volume)...........

As YR said, you can't really see the short side turn...........but from what i can see, it seam to come of sharp!?!

Take you finger and fill how the floor turns. it should be a fairly consistent radius from the last seat cut to where you can see the floor in the picture.

It would be interesting to see what the ratio is between intake and exhaust ports (CC Volume)...........

MOPAROFFICIAL

If it has tits, it's a liabilititty.

will definitely do so Monday. Time is an issue, though. Honestly at this point, I'd rather buy some damn off the shelf cam that will run decent and call it a day. I'm so frustrated. Over there at Bullet, Tim is supposed to be the Mopar guy. Its like getting ahold of the president of the US. You know the deal, ship it back. Wait 6 weeks for a regrind. Then it sits on a shelf waiting to be shipped for a week.

Im thinking about buying a racehorse. It runs or it don't. Period.

There is no one and only in the cam biz.

Tim wanted to grind me something along the same lines and I said to him "uh...hmm ilk have to think on that"...aka I'm callin someone else. You should throw a dual plane on it lol that'll yield neat results.

There is a time...but when a certain cam guy is tossing split lifts/durations at you while you're talking about a modified head with dialed ratios and matched induction to exhaust...I'm running and never looking back.

j par

Well-Known Member

Well I've kept my mouth shut and listened patiently and learned . Now it's time for me to give my experience like I always do because you know I don't really know nothing except for what has happened to me . I took the duster out yesterday and you know I have my stupid hillbilly Stroker but also the four speed and 410 gears as you have . By all my calculations I think I have around 375 horsepower at the back tires and anything over three-and-a-half Grand on the street at anything over 1/4 throttle and the back tires are ignited all over the place. I'm having a hard time imagining what an extra hundred or hundred and fifty horsepower would feel like on the street ? CARRY ON...

="Ironmike, post: 1971595524, member: 11850"]***I'm not really chasing a number.*** ???? Not a race car????. It's a street/strip Demon 4 speed 4:10 gears. Its 3090lbs with me in it. It gets run hard on the street.[/QUOTE]

="Ironmike, post: 1971595524, member: 11850"]***I'm not really chasing a number.*** ???? Not a race car????. It's a street/strip Demon 4 speed 4:10 gears. Its 3090lbs with me in it. It gets run hard on the street.[/QUOTE]

MOPAROFFICIAL

If it has tits, it's a liabilititty.

If I built this engine I would be addressing the power down low-the HP is fine. The heads are the limit. Put a small *** header with a long collector with a port to header mismatch-yes mismatch and watch the bottom end tq swell. J.Rob

Ding ding

-