But they have zero support backing them up. Nothing. Even welded, they'd fold over.My only complaint with that setup would be the fact that the upper supports are bolted to the frame rails. If you're going that far, weld 'em in. Kinda like subframe connectors.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Coil-Over Conversion Suspension

- Thread starter Chris Bolander

- Start date

-

Exactly.Uhh....

View attachment 1716387081

How can anyone build a suspension and steering setup then do something as short sighted as this? That is as bad as the RMS design. Single shear, cantilevered with a Heim joint will not outlast a dropped arm like the stock lower ball joint design had. THIS to reduce bump steer?

It probably rides and steers great going on and off a trailer and up to 15 mph on smooth roads.

mopowers

Well-Known Member

I was referring to the photo you posted.But they have zero support backing them up. Nothing. Even welded, they'd fold over.

And saying “improved geometry was never stated” and then being offended when someone say it doesn’t handle better is a smokescreen. If you expected it to handle better, it must have better geometry. Unless stiffer springs and better shocks are the source of the better handling, and those can be added to a TB suspension too so that can’t be the source of the improvement.

The COC companies need to be honest about their offerings. Frees up space for headers, offers a rack, but loads the rails differently than factory and uses a short MII spindle. And stop talking about handling and geometry unless you publish some data. And by data I don’t mean “the stock worn out suspension didn’t hold a candle to the new double adjustable shock coil over kit we swapped in”.

To the best of my 20 year recollection, I have only had one customer call me complaining about how his car drove / handled. He said it moved all around at speed. I was shocked to say the least and asked him what specs he had used when he aligned it. He replied he had not yet aligned it. Is that the smokescreen you are talking about???

I admire anyone that offers components to maybe (or maybe not) better our hobby. I'm glad they at least try. To bad some of us just do not meet your expectations.

DionR

Well-Known Member

To the best of my 20 year recollection, I have only had one customer call me complaining about how his car drove / handled. ...Is that the smokescreen you are talking about???

Too bad that doesn't fit the definition of "data".

So yeah, that fits the what I think of as a smokescreen.

I admire anyone that offers components to maybe (or maybe not) better our hobby. I'm glad they at least try. To bad some of us just do not meet your expectations.

Look, I honestly do like you. I like what you bring to the hobby, I like how you run your business, I like your product and if I was look for one I would buy yours. Even after butting heads here over and over. So the only expectations you fail to meet is that you won't admit that no one has any real facts to back up the support that a COC handles better or has improved geometry. Honestly, there isn't much on a TB suspension either, but there is more than any COC kit producer has shown.

Yeah. That's the HDK setup. Clearly a stronger choice.I was referring to the photo you posted.

Too bad that doesn't fit the definition of "data".

View attachment 1716388366

So yeah, that fits the what I think of as a smokescreen.

Look, I honestly do like you. I like what you bring to the hobby, I like how you run your business, I like your product and if I was look for one I would buy yours. Even after butting heads here over and over. So the only expectations you fail to meet is that you won't admit that no one has any real facts to back up the support that a COC handles better or has improved geometry. Honestly, there isn't much on a TB suspension either, but there is more than any COC kit producer has shown.

I get it, and you seem to be a little like me,.... hard headed. BTW, welcome to the club, I'm the president.

My goals never included "improved geometry", but to optimize with the most cost effective available off the shelf components in a compact, fully adjustable, adaptable with other aftermarket components and multi-Mopar engine combinations ....all in an affordable bolt-in coil over / rack and pinion package. Believe me, like you, I shake my head at the "improved geometry" claims. However, does a modern rack and pinion drive better better than even an upgraded 60's-70's steering box and their related components? My customers (my data), tell me.... hell yes!

I value your input, it is the only way I can learn in hopes to improve, but as far as suppling data. Gerst taught me an important lesson. Do not give out any information regardless of what bullshit story someone (Gerst) tells you. I have had several ask for specific data, in EVERY case, they were simply looking to build their own and by-pass their own R&D.

Denny

Last edited:

- Joined

- Oct 17, 2009

- Messages

- 162

- Reaction score

- 90

Best of luck Chris Bolander!!!! Took a look at your page and like what I see thus far. Hope to see your gonna build some for the 73/73 Satellite & Road Runners too! Btw. I just posted your ad to the group on Facebook there. Good Luck!!!!

^ this right here. Where is the baseline info on a TB suspension that we are measuring against? Who has put a stock suspension through a proper suspension analysis software and shared the results? And what is the baseline that a TB suspension should be compared against? It seems to me that in order to have a fair, “data” driven comparison we need all 3; Ideal geometry vs stock torsion bar vs coil-over vendor’s data. Otherwise it’s just one persons “anecdata” vs the others. And anecdotal data does not a fact make.Too bad that doesn't fit the definition of "data".

View attachment 1716388366

Honestly, there isn't much on a TB suspension either, but there is more than any COC kit producer has shown.

BillGrissom

Well-Known Member

My concern too just looking at it as a mechanical engineer. The spring mostly puts a tensile load on the upright, but the lateral force is still high, compared to the thin section at the bottom of the upright where the bending load is highest. But then I haven't run stress calculations. One would need to design for metal-fatigue life since it sees repeated loads from every bump, and how many potholes the car will hit is hard to guess.... "Only" 3/16" plate with no backup support.

As example, one can buy torsion springs for a garage door with infinite fatigue life, but twice as heavy and costly so most people select smaller ones and live with the life. One guy posted a web article discussing his experience. He has 4 garage doors at home, so much spring-failure experience. He found when the springs break quite predictable, despite fatigue failure being a bit random. He had to replace a spring about every 10 years (door opened at least twice per day), with the size he chose. Ran across that while researching fixing my broken spring. Another example, I installed an after-market AC bracket in my 1985 M-B 300D. The guy fabbing them was a regular on a web forum. Looked rugged w/ 1/2" steel plate, but I found it had cracked thru in several places after ~2 years, so it couldn't keep the belt tensioned anymore. Whole-lot-of-shakin-going-on in a diesel engine, so even OE parts typically crack (engine-mounted air filter bracket, turbo oil tube brackets). TBD if the upright in this suspension will suffer similar cracks.

DionR

Well-Known Member

^ this right here. Where is the baseline info on a TB suspension that we are measuring against? Who has put a stock suspension through a proper suspension analysis software and shared the results?

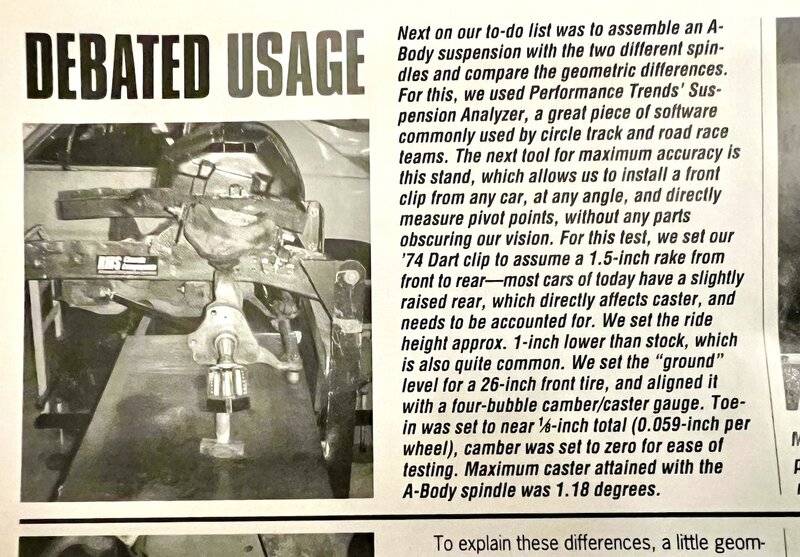

Here is a chart that includes the roll center of a stock TB suspension setup at a base 1" lower using a stock A-Body spindle and then compared to an F-Body spindle.

Full post here - DOES THE HDK SUSPENSION K-MEMBER HANDLE BETTER THAN A T-BAR SUSPENSION? and here - 12:05 Garage- ’70 Duster build

Far as I know, no one has done the stock suspension in a suspension analyzer. I had planned to, but I was down with an injury last spring at that point and as I got better, I never got it done.

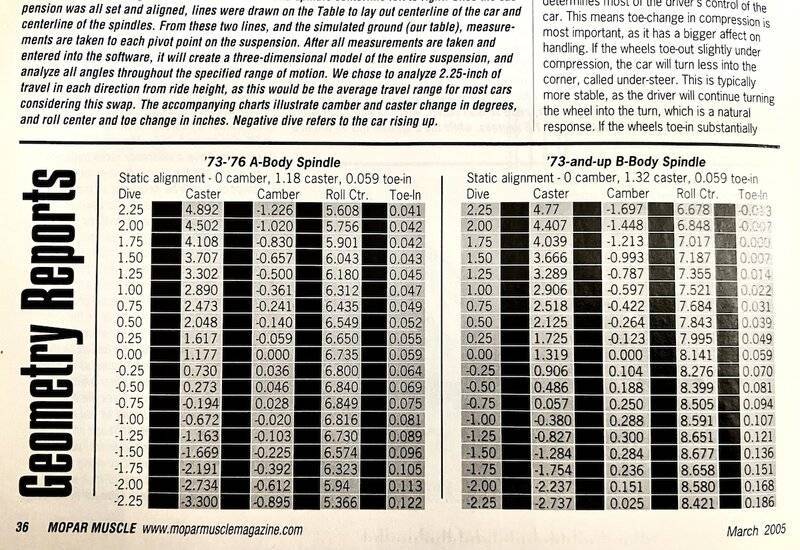

Joe did his HDK setup after swapping in 2" longer UBJ's and his roll center was at about 2.4".

Full post here - 12:05 Garage- ’70 Duster build

I asked him were it was with the originally supplied UBJ and he said he made some estimates and it was underground.

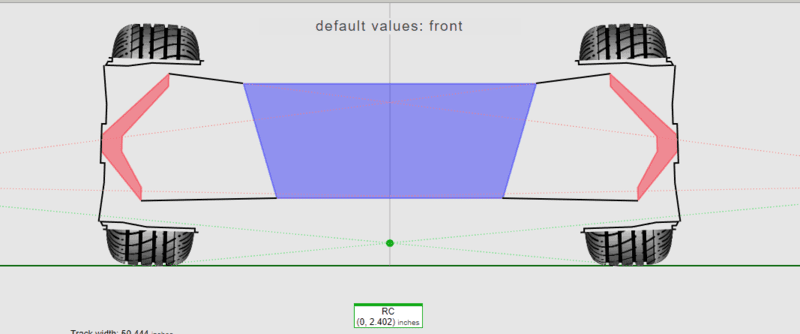

I messed with it but not with as much precision as this time and it was 4" below the ground. I believe this was due to the UCA and LCA angles never intersecting. I don't quite understand the math behind that. Picture the LCA near level and the UCA pointing to the sky.

This is why I asked the OP about the short MII spindle. If the LCA is flat and the UCA is slopes down from the frame rail to the UBJ, the roll center is going to be underground and "less" than optimal. Now, the OP's kit could have raised the LCA mount point to get the UCA sloping the other way, which might be why it needed such a long spacer to correct his bump steer. But doing that makes for even less travel on the shock, which can already be pretty limited. The HDK kit has the upper shock mount pretty high to avoid that situation. Joe used longer UBJs to help with the UCA angle. Personally, I think a taller upright is the better answer.

Here is a visual to help with why (generally speaking) an UCA sloping down is bad:

Here are Joe's camber gains before the longer UBJ so you can compare to the above chart:

Ride height +3 - 1.6 degrees

Ride height +2 - .7 degrees

Ride height +1 - .1 degrees

Ride height - 0 degrees

Ride height -1 - .3

Ride height -1.5 - .7

And after the 2" longer UBJ:

Ride height +2 - 1.8 degrees

Ride height +1.5 - 1.4 degrees

Ride height +1 - .8 degrees

Ride height +.5 - .4 degrees

Ride height - 0 degrees

Ride height -.5 - .3 degrees

Ride height -1 - .3 degrees

Ride height -1.5 - .6 degrees

Ride height -2 - .6 degrees

After the longer UBJ, looks like Joe is getting more camber gain than the F-Body spindle as he compresses the suspension. At the same time, roll center is still lower than the F-Body spindle and body roll will reduce camber on the outside tire. So then stiffer springs/shocks and/or a bigger swaybar are potential fixes.

The other thing is, I'm not sure where a 1" lower ride height puts the stock LCA. If it is still sloping down from the center of the car to the LBJ, then lowering the TB car even further will make the numbers in the chart even better.

Based on that data (there's that word again), I feel pretty comfortable saying that any COC kit that puts the LCA pivot in close to the factory location will never have improved geometry even with a 2" longer UBJ. Moving the LCA pivot up into the car would help or even fix that, at the expense of shock travel and bump steer correction spacers.

And what is the baseline that a TB suspension should be compared against? It seems to me that in order to have a fair, “data” driven comparison we need all 3; Ideal geometry vs stock torsion bar vs coil-over vendor’s data. Otherwise it’s just one persons “anecdata” vs the others. And anecdotal data does not a fact make.

Just my opinion, but I think it is pointless to compare a COC to a stock suspension. I don't see any useful purpose behind the work.

So, I would propose that the TB suspension be set up with what is (I think) generally the target ride height and alignment for a handling build. So, lowered until the LCA is about horizontal and alignment numbers in the range of +3 to +6 degrees of caster and -1 degree of camber. The caster range allows for potentially just offset UCA bushings or the adjustable ones @BergmanAutoCraft sells. I vote adjustable myself.

Then compare this to an out of the box setup from the suppliers. Not an optimized one like Joe runs, because most of the buyers don't have the drive Joe does and because most of the suppliers are touting "improved geometry" so the kit should stand on it's own.

Doing this back to back on the same car or at least in the same shop, with the same wheels would remove the potential for doubt to creep in. At the same time, I don't think we are talking about comparing 4 digit numbers either so close enough works (in my opinion).

Last edited:

DionR

Well-Known Member

I'm sure you are prepared to hear people call it another Mustang 2 suspension when the only component that is M2 is the spindle. I hear the same thing with my HDK. This leads me to my next question. Did you look at using an aftermarket GM type spindle? There are tons of options out there for height and steering arm configuration options, which make them attractive to me. There are even options for spindles made to accept a corvette or late model mustang hub. I'm not familiar enough with them to know how different the SAI is compared to the M2 spindles. Speedtech makes a killer forged aluminum spindle that I'd love to try on my HDK. They are kinda cost prohibitive just to "try".

It's not the Speedtech spindle, but I wonder if these have any potential?

They would require a different UCA attachment since the UBJ is in the upright, and no idea if they are any taller than the MII spindle with a 2" longer UBJ.

Just tossing it out there.

We probably should have moved this discussion into its own topic to avoid polluting a new product announcement, but, too late now.

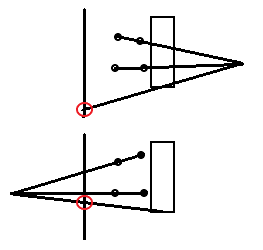

So were to begin....maybe with this: I have put my mopar's suspensions into an analyzer. I used Front Suspension Geometry Analyzer from Autoware. I plotted out iterations of a stock set-up, drop spindle set up, and the specific set-up used in my E body. I've plotted static positions as well as cornering positions to evaluate movement of the various intersection points and geometry changes. I'll stick a couple of screen shots of these in here of a static overall position and the bump analysis. If you look at the list of potential analysis points in the bump shot, you can see there are numerous ways to look at what is happening there.

Now, before someone asks me to post of new analysis and find any additional information, I'll offer this...these are screen grabs I took in 2010 for another forum I was participating on at that time. The program I was using was on a DOS based operating system. I have upgraded from that several times over and no longer have the ability to run this program and have never bothered to purchase a new version of the program compatible with my new computers. So unless I reconnect and reboot that old system, I can't contribute any new detail. But it can be done if someone wants to do it.

So were to begin....maybe with this: I have put my mopar's suspensions into an analyzer. I used Front Suspension Geometry Analyzer from Autoware. I plotted out iterations of a stock set-up, drop spindle set up, and the specific set-up used in my E body. I've plotted static positions as well as cornering positions to evaluate movement of the various intersection points and geometry changes. I'll stick a couple of screen shots of these in here of a static overall position and the bump analysis. If you look at the list of potential analysis points in the bump shot, you can see there are numerous ways to look at what is happening there.

Now, before someone asks me to post of new analysis and find any additional information, I'll offer this...these are screen grabs I took in 2010 for another forum I was participating on at that time. The program I was using was on a DOS based operating system. I have upgraded from that several times over and no longer have the ability to run this program and have never bothered to purchase a new version of the program compatible with my new computers. So unless I reconnect and reboot that old system, I can't contribute any new detail. But it can be done if someone wants to do it.

Next up, there always seems to be someone new entering the after-market suspension game. I always am encouraged to see that. Unfortunately not all of them will stick around. XV came on to the scene going gangbusters, but also went bust seemingly as fast. Although I think you can still get their parts from an engineering group that bought them out and is limping it along still.

Morrison is on the verge of releasing a new coil over system. Alston offers their GStreet spindle units that could be adapted to a new system if someone was so inclined. Also, I've posted this elsewhere, but one could always look at used pro racing series parts that could be used to create a new system. Below is a view of some used ARCA road race spindles I have sandwiching a stock mopar spindle.

It all comes down to what do you want, how much are you willing to pay for it and what to you want to use to get there. In that regard, suspensions are no different than engines.

Morrison is on the verge of releasing a new coil over system. Alston offers their GStreet spindle units that could be adapted to a new system if someone was so inclined. Also, I've posted this elsewhere, but one could always look at used pro racing series parts that could be used to create a new system. Below is a view of some used ARCA road race spindles I have sandwiching a stock mopar spindle.

It all comes down to what do you want, how much are you willing to pay for it and what to you want to use to get there. In that regard, suspensions are no different than engines.

I'm sure you are prepared to hear people call it another Mustang 2 suspension when the only component that is M2 is the spindle. I hear the same thing with my HDK.

That’s because they’re both MII based systems. Uses MII based spindles, MII steering rack, steering arms, etc.

Is the suspension on my Duster not Mopar suspension? I run the same SPC UCA’s you do. I run QA1 tubular LCA’s, 1.12” torsion bars, and FMJ spindles. The lower ball joints are probably the only thing that matches the A-body factory design, even the upper ball joints are Howe so the serviceable guts are different. But I would imagine that even though the factory design suspension parts on my car can be counted on a single hand you'd still call that factory suspension?

Besides cars, I'm sure there were lots of cool things that came out in 1970. Just like cars and all those things, I'm sure they have improved in 55 years.

And the MII design is how old? Oh, right, it’s 50+ years old too. Most suspension designs are at LEAST 50 years old. Even the MacPherson strut is about that old.

I don't remember Joe going backwards anytime, in fact, my memory had him up to speed right out of the gate. Of course, Joe being Joe, massaged it to HIS liking.

On a side note..... I bet it made his Gen III swap a whole lot easier.

I mean his first set of numbers showed that a factory suspension car lowered 1" with FMJ spindles and really basic alignment settings had better camber gain numbers than the HDK as delivered, so, it wouldn't say it's a forward move. Even Joe's improved numbers are well within reach with the torsion bar suspension.

To the best of my 20 year recollection, I have only had one customer call me complaining about how his car drove / handled. He said it moved all around at speed. I was shocked to say the least and asked him what specs he had used when he aligned it. He replied he had not yet aligned it. Is that the smokescreen you are talking about???

I admire anyone that offers components to maybe (or maybe not) better our hobby. I'm glad they at least try. To bad some of us just do not meet your expectations.

Right, so, you're saying that most customers don't complain and then saying some customers don't even know they need an alignment in the same post. Seems to me like you're saying most customers don't understand suspension stuff at all, so, most of them not complaining isn't all that meaningful. This is why people that understand suspension want more information, not just a "my customers love it" response. That's great, but it doesn't mean it's better suspension.

I get it, and you seem to be a little like me,.... hard headed. BTW, welcome to the club, I'm the president.

My goals never included "improved geometry", but to optimize with the most cost effective available off the shelf components in a compact, fully adjustable, adaptable with other aftermarket components and multi-Mopar engine combinations ....all in an affordable bolt-in coil over / rack and pinion package. Believe me, like you, I shake my head at the "improved geometry" claims. However, does a modern rack and pinion drive better better than even an upgraded 60's-70's steering box and their related components? My customers (my data), tell me.... hell yes!

I value your input, it is the only way I can learn in hopes to improve, but as far as suppling data. Gerst taught me an important lesson. Do not give out any information regardless of what bullshit story someone (Gerst) tells you. I have had several ask for specific data, in EVERY case, they were simply looking to build their own and by-pass their own R&D.

Denny

A rack and pinion doesn't objectively improve handling beyond perhaps saving a few pounds. This is one of those things that people want because they like the feel of it better, and one of the reasons people will say the entire coil over conversion feels better- the rack feels nicer subjectively. But again, it won't make your car handle any better at all. I would bet that most of the folks saying their coil over conversion feels better than factory suspension are primarily basing that on the feel of a new rack vs a worn out steering box and tie rod ends. That's not a meaningful comparison.

As far as proprietary, sorry, it's a lame excuse. Most of the suspension points remain factory Mopar, anyone can measure those if they're so inclined. And if someone really wanted to build a coil over conversion to sell as a business it's not hard to run suspension plots. Providing the plots like were posted in the Mopar Muscle article doesn't even tell you any of the suspension points, and even those aren't the hardest part of building a coil over conversion system anyway.

The simple reality is if you run an MII based spindle with the Mopar suspension points you need to keep to bolt the conversion onto the car the geometry will not improve vs the factory geometry because the MII spindle is too short. Can you adjust it with taller ball joints? Sure. But you can also put adjustable UCA"s and alter the ball joint height on the torsion bar suspension if you want.

Here is a chart that includes the roll center of a stock TB suspension setup at a base 1" lower using a stock A-Body spindle and then compared to an F-Body spindle.

Full post here - DOES THE HDK SUSPENSION K-MEMBER HANDLE BETTER THAN A T-BAR SUSPENSION? and here - 12:05 Garage- ’70 Duster build

Far as I know, no one has done the stock suspension in a suspension analyzer. I had planned to, but I was down with an injury last spring at that point and as I got better, I never got it done.

Joe did his HDK setup after swapping in 2" longer UBJ's and his roll center was at about 2.4".

Full post here - 12:05 Garage- ’70 Duster build

I asked him were it was with the originally supplied UBJ and he said he made some estimates and it was underground.

This is why I asked the OP about the short MII spindle. If the LCA is flat and the UCA is slopes down from the frame rail to the UBJ, the roll center is going to be underground and "less" than optimal. Now, the OP's kit could have raised the LCA mount point to get the UCA sloping the other way, which might be why it needed such a long spacer to correct his bump steer. But doing that makes for even less travel on the shock, which can already be pretty limited. The HDK kit has the upper shock mount pretty high to avoid that situation. Joe used longer UBJs to help with the UCA angle. Personally, I think a taller upright is the better answer.

Here is a visual to help with why (generally speaking) an UCA sloping down is bad:

Here are Joe's camber gains before the longer UBJ so you can compare to the above chart:

And after the 2" longer UBJ:

After the longer UBJ, looks like Joe is getting more camber gain than the F-Body spindle as he compresses the suspension. At the same time, roll center is still lower than the F-Body spindle and body roll will reduce camber on the outside tire. So then stiffer springs/shocks and/or a bigger swaybar are potential fixes.

The other thing is, I'm not sure where a 1" lower ride height puts the stock LCA. If it is still sloping down from the center of the car to the LBJ, then lowering the TB car even further will make the numbers in the chart even better.

Based on that data (there's that word again), I feel pretty comfortable saying that any COC kit that puts the LCA pivot in close to the factory location will never have improved geometry even with a 2" longer UBJ. Moving the LCA pivot up into the car would help or even fix that, at the expense of shock travel and bump steer correction spacers.

Just my opinion, but I think it is pointless to compare a COC to a stock suspension. I don't see any useful purpose behind the work.

So, I would propose that the TB suspension be set up with what is (I think) generally the target ride height and alignment for a handling build. So, lowered until the LCA is about horizontal and alignment numbers in the range of +3 to +6 degrees of caster and -1 degree of camber. The caster range allows for potentially just offset UCA bushings or the adjustable ones @BergmanAutoCraft sells. I vote adjustable myself.

Then compare this to an out of the box setup from the suppliers. Not an optimized one like Joe runs, because most of the buyers don't have the drive Joe does and because most of the suppliers are touting "improved geometry" so the kit should stand on it's own.

Doing this back to back on the same car or at least in the same shop, with the same wheels would remove the potential for doubt to creep in. At the same time, I don't think we are talking about comparing 4 digit numbers either so close enough works (in my opinion).

A 1" lower ride height does not put the control arms parallel to the ground, they will still slope down from the pivots to the ball joints. Because of how the FSM measures the ride height its easy to know this, the factory spec puts the ball joint 1-7/8" lower than the pivot. So, you have to lower the car ~2" from factory to make the control arms slope the other way.

So yes, you will get better geometry out of the factory suspension than what is published in that article just by lowering the car ~2" from factory. Peter Bergman runs lowered with a 1/2" taller ball joint, I'd be willing to bet those numbers are better again.

I honestly don't think a head to head would even necessarily tell you which one is "better", because frankly you can tune a coil over conversion or the factory suspension to have basically the same camber gain, roll centers etc if you wanted to make the adjustments. Coil over conversions get a rack, which just subjectively feels better. And header space, even though if you're running a mopar engine the best headers are probably still ones that fit with torsion bars. Beyond that either one can be tuned.

We probably should have moved this discussion into its own topic to avoid polluting a new product announcement, but, too late now.

So were to begin....maybe with this: I have put my mopar's suspensions into an analyzer. I used Front Suspension Geometry Analyzer from Autoware. I plotted out iterations of a stock set-up, drop spindle set up, and the specific set-up used in my E body. I've plotted static positions as well as cornering positions to evaluate movement of the various intersection points and geometry changes. I'll stick a couple of screen shots of these in here of a static overall position and the bump analysis. If you look at the list of potential analysis points in the bump shot, you can see there are numerous ways to look at what is happening there.

Now, before someone asks me to post of new analysis and find any additional information, I'll offer this...these are screen grabs I took in 2010 for another forum I was participating on at that time. The program I was using was on a DOS based operating system. I have upgraded from that several times over and no longer have the ability to run this program and have never bothered to purchase a new version of the program compatible with my new computers. So unless I reconnect and reboot that old system, I can't contribute any new detail. But it can be done if someone wants to do it.

View attachment 1716388596

View attachment 1716388597

Yes! You ran the 2" drop spindles against a lowered E-body with factory suspension for me back on Cuda-Challenger.

There are lots of programs out there, some are super expensive. I have one that's actual Excel based, it's just taking suspension points and doing math. I haven't messed with it much but I need to plot out all the points on my Duster and run it through.

DionR

Well-Known Member

A 1" lower ride height does not put the control arms parallel to the ground, they will still slope down from the pivots to the ball joints. Because of how the FSM measures the ride height its easy to know this, the factory spec puts the ball joint 1-7/8" lower than the pivot. So, you have to lower the car ~2" from factory to make the control arms slope the other way.

So yes, you will get better geometry out of the factory suspension than what is published in that article just by lowering the car ~2" from factory. Peter Bergman runs lowered with a 1/2" taller ball joint, I'd be willing to bet those numbers are better again.

Thanks! I was guessing that was the case but didn't even think to look at the FSM to see what the spec is. I think I have used the factory spec maybe only once and after that I figured out it was too tall and have been low ever since.

Dion R

to clarify /correct your data....Joe installed 2" extended stud ball joints, The HDK package standard upper ball joint is a 1" extended, so he raised the UCA ball joint receiver 1" from delivered. I would consider the 1-1/2 or 2" extended as an option IF someone built a quality piece. The Allstar extended ball joints leaves a lot to be desired. In testing, I have replaced my share with less that 200 miles on them, IMO, they are Chinese junk.

The Qa1 with 1" extended upper ball joint w/ adjustable pre-load is my pick, maybe someday they will make 1-1/2 and 2" extended studs for their housings.

To put a period on my comments, rarely, if ever does roll center come into the discussion when my customers are discussing their suspension needs......imagine that?. The only time I have seen it obsessed over is by the amateur auto X crowd / railbirds here on FABO. As far back as I can remember, it has never been the topic of discussion at any car event I have attended in the last 50 years. Of course, maybe I'm hangin' with the wrong crowd.

Good luck guys,

Denny

to clarify /correct your data....Joe installed 2" extended stud ball joints, The HDK package standard upper ball joint is a 1" extended, so he raised the UCA ball joint receiver 1" from delivered. I would consider the 1-1/2 or 2" extended as an option IF someone built a quality piece. The Allstar extended ball joints leaves a lot to be desired. In testing, I have replaced my share with less that 200 miles on them, IMO, they are Chinese junk.

The Qa1 with 1" extended upper ball joint w/ adjustable pre-load is my pick, maybe someday they will make 1-1/2 and 2" extended studs for their housings.

To put a period on my comments, rarely, if ever does roll center come into the discussion when my customers are discussing their suspension needs......imagine that?. The only time I have seen it obsessed over is by the amateur auto X crowd / railbirds here on FABO. As far back as I can remember, it has never been the topic of discussion at any car event I have attended in the last 50 years. Of course, maybe I'm hangin' with the wrong crowd.

Good luck guys,

Denny

Last edited:

Zigtf216

Active Member

I like that one tooExactly.

DionR

Well-Known Member

To put a period on my comments, rarely, if ever does roll center come into the discussion when my customers are discussing their suspension needs......imagine that?. The only time I have seen it obsessed over is by the amateur auto X crowd / railbirds here on FABO. As far back as I can remember, it has never been the topic of discussion at any car event I have attended in the last 50 years. Of course, maybe I'm hangin' with the wrong crowd.

Nothing wrong with hanging with the straight line crowd. There are good guys on both sides of the fence. It's when we cross over and don't know the lingo or importance of something that knowledge is increased, provided we are humble enough to learn. The trick is not to cross over and then act like the stuff on the other side of the fence always works just as well here. Sometimes, stuff does cross over and improve the breed on the other side but not always.

I for one would think a street/strip car that doesn't roll on an on ramp like a row boat in a bad storm would be a good thing. Same with an Ackerman angle that doesn't make the car dangerous getting on the return road like most rack and pinion kits do (the non-COC kits). But there are certainly places where it doesn't make much sense to spend time and energy to improve it if good enough gets the job done. Not saying a COC rolls in a corner or has bad Ackerman angle, just using those as examples of how a street/strip car might benefit from improved handling even if the threshold is much lower.

But the use case of the car can have a significant impact on it and on this side of the fence, spending $6-8K on suspension parts that really only add a rack and pinion and leave a lot to be desired for suspension geometry doesn't make much sense to me. The use case of an autocross or road course car almost mandate that things like roll center, scrub radius and center of gravity, to name a few, are paid attention to. And not talking about it doesn't mean it's not important.

I think Joe's improvements had shown that a COC kit shouldn't be assumed to be able to handle, he has done very well making it work. But out of the box, so far I don't see anything worth the prices.

DionR

Well-Known Member

I went looking for the Speedtech spindles that Joe mentioned earlier in this thread and if anyone can make me feel like they have done the design work and engineering for a COC, it would be them. Unfortunately, they want real money for their stuff ($12.5K with their headers but without brakes), and they don't offer an A-Body kit. Fairly substantial structure under the floor that the bolt in frame attaches too after the front frame rails are removed plus an optional downtube . And a 315/30R18 tire under the fender.

Not something I believe I will ever be in the market for, just too much money and no kit to fit my car. But in my mind, this is the extreme end of "all out". When I think of throwing money at a COC to remove all the compromises, this is what I think of.

Not something I believe I will ever be in the market for, just too much money and no kit to fit my car. But in my mind, this is the extreme end of "all out". When I think of throwing money at a COC to remove all the compromises, this is what I think of.

Zigtf216

Active Member

For $12.5k I will build it myself or stick with torsion bars! That is the nicest conversion I’ve seen. Looks heavy

DionR

Well-Known Member

For $12.5k I will build it myself or stick with torsion bars!

Completely agree.

To be clear, I only tossed it out there as an example of avoiding some of the compromises. By building their own frame rails, they can design them to support the weight of the car and set their own suspension mounting points so geometry can be optimized. At the same time, they compromised on the frame rails so the wide tires fit and they still have a bunch of steering angle at the expense of a narrow engine bay. I suspect that is why they offer custom headers (for $1700).

And based on what I see, I bet they actually did run it through a suspension analyzer. No idea if they would post it, but they have used too much technology in the design to not have done it.

I do know the class winning Grand Champion Super Bee from last years Moparty is getting this kit. He has the QA1 kit right now, but also has some frame rail rot. So in some ways, this might be the easier fix for him.

And this suspension seems to dominate the OPTIMA series as it is under the blue Camaro that has won his class several years, as well as the Blazer that won last years truck class. Not that either one won just on suspension alone. The Camaro is sporting all kinds of do-dads including ABS. But I don’t think anyone can be competitive in that arena without a 315 tire at least, anymore.

racerjoe

Well-Known Member

These are the spindles I was referring to --> https://speedtechperformance.com/product/tall-height-ats-hot-rod-subframe-spindles/Completely agree.

To be clear, I only tossed it out there as an example of avoiding some of the compromises. By building their own frame rails, they can design them to support the weight of the car and set their own suspension mounting points so geometry can be optimized. At the same time, they compromised on the frame rails so the wide tires fit and they still have a bunch of steering angle at the expense of a narrow engine bay. I suspect that is why they offer custom headers (for $1700).

And based on what I see, I bet they actually did run it through a suspension analyzer. No idea if they would post it, but they have used too much technology in the design to not have done it.

I do know the class winning Grand Champion Super Bee from last years Moparty is getting this kit. He has the QA1 kit right now, but also has some frame rail rot. So in some ways, this might be the easier fix for him.

And this suspension seems to dominate the OPTIMA series as it is under the blue Camaro that has won his class several years, as well as the Blazer that won last years truck class. Not that either one won just on suspension alone. The Camaro is sporting all kinds of do-dads including ABS. But I don’t think anyone can be competitive in that arena without a 315 tire at least, anymore.

They are approximately 1/2" taller than the Wilwood M2 spindle. Besides the height advantage, there's a ton of commercially available steering arm options for correcting ackerman and bumpsteer. $1400 is out of my budget for "trying" something. I do, however, think this would require a 1/2" taller ball joint to keep the LCAs level, at least on my car.

Chris Bolander

Member

- Joined

- Apr 28, 2016

- Messages

- 12

- Reaction score

- 16

Ahh this turned into a can of worms. As others have said these conversions aren’t for everyone so I’m not going to get on here to debate anyone because I’m not a cupcake and will never make everyone happy.. People will always find something to complain about. What I will say, is there are SEVERAL comments about this isn’t “improved” geometry it’s “corrected” but isn’t a correction an improvement? As Denny stated alot of the things guys are complaining about are dependent upon car setup. When we ran through the suspension analysis we used stock ride heights.. Can you make TB suspension work absolutely. I wanted to offer something quality, drivable and adjustable to what each individual driver wants, there isn’t a cookie cutter setup. A modernization of these classic cars that make them handle and drive like something new with the option to update to a modern engine package as well… No swapping k-frame just different engine mounts..

I did look at some GM spindles but didn’t want to get into the cost of what the corvette spindles were going to be..Welcome to the brutal world of Mopar aftermarket suspension. I wish you the best.

I have a few questions/comments and do not mean anything negative, so please don't take it the wrong way. As many people have stated, if you mention improved geometry, people that actually understand geometry will want to know what is improved. I realize it is very dependent on tire size/ride height, but I think you should be suggesting these things. Companies like Detroit Speed and Total Cost Involved recommend a tire height to use with their suspension systems. How are your customers to realize the improved benefits if they don't know what tire to run? I'm really curios what the camber gain per inch is along with the roll center height.

I'm sure you are prepared to hear people call it another Mustang 2 suspension when the only component that is M2 is the spindle. I hear the same thing with my HDK. This leads me to my next question. Did you look at using an aftermarket GM type spindle? There are tons of options out there for height and steering arm configuration options, which make them attractive to me. There are even options for spindles made to accept a corvette or late model mustang hub. I'm not familiar enough with them to know how different the SAI is compared to the M2 spindles. Speedtech makes a killer forged aluminum spindle that I'd love to try on my HDK. They are kinda cost prohibitive just to "try".

-

Similar threads

- Replies

- 20

- Views

- 9K

- Replies

- 4

- Views

- 377