myasylum

Well-Known Member

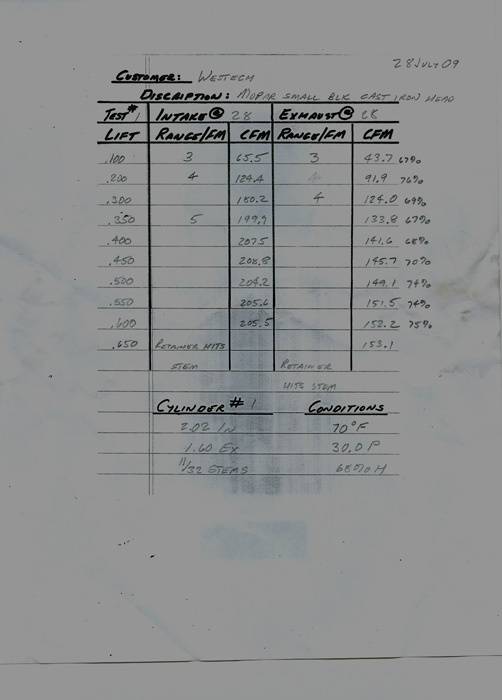

I just ported my first set of stock heads myself. I have no idea how good I did. I had someone flow test them and they wrote done the results. When I ask him how good it was he just said, "It's ok." and thats all he said!

What is this telling me?

Is this bad?

Thanks!

What is this telling me?

Is this bad?

Thanks!