LIME TWIST DART

Well-Known Member

What considerations are there in deciding on a splined steering shaft or a DD shaft?

Pros, Cons? Tips, Safety?

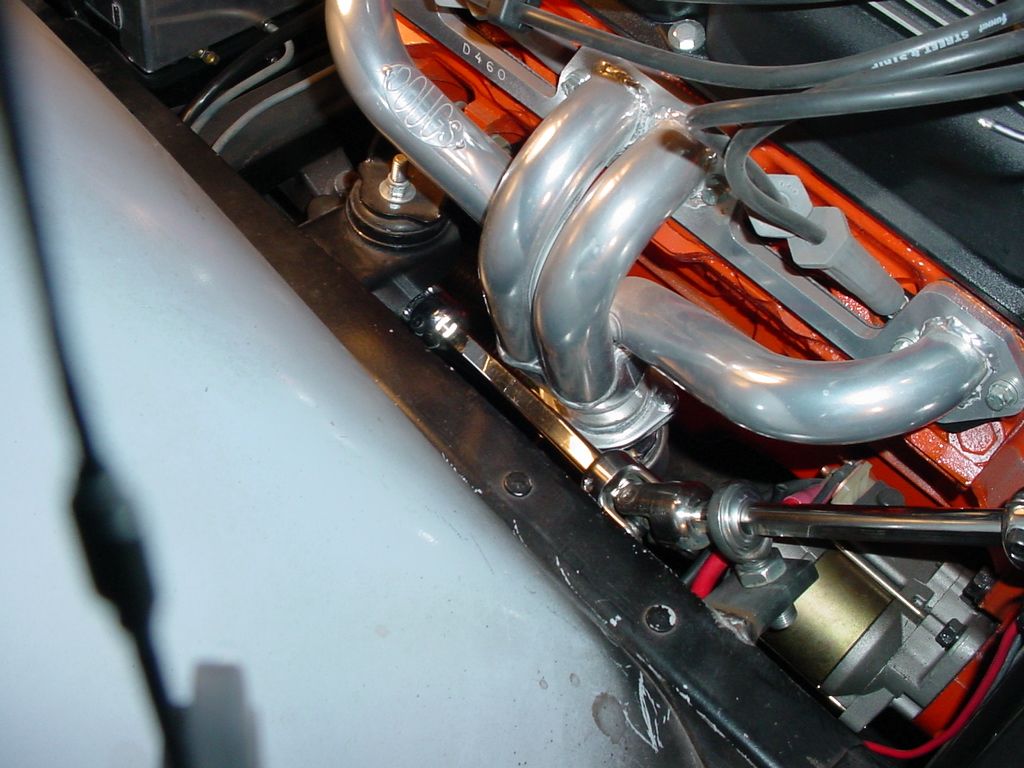

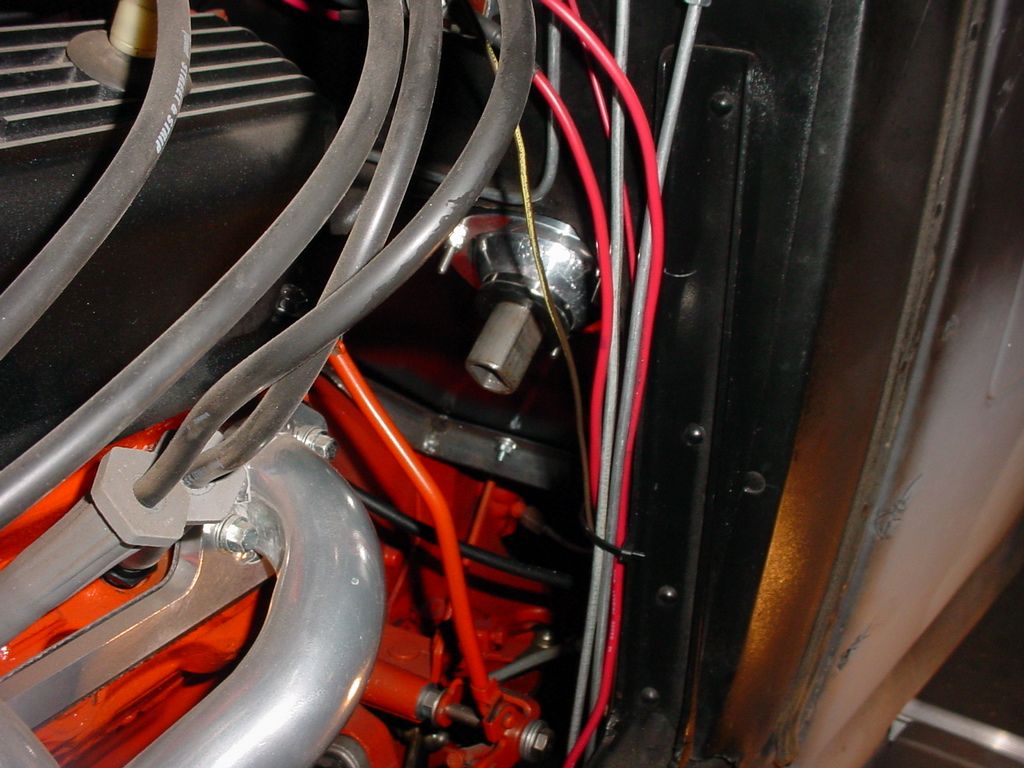

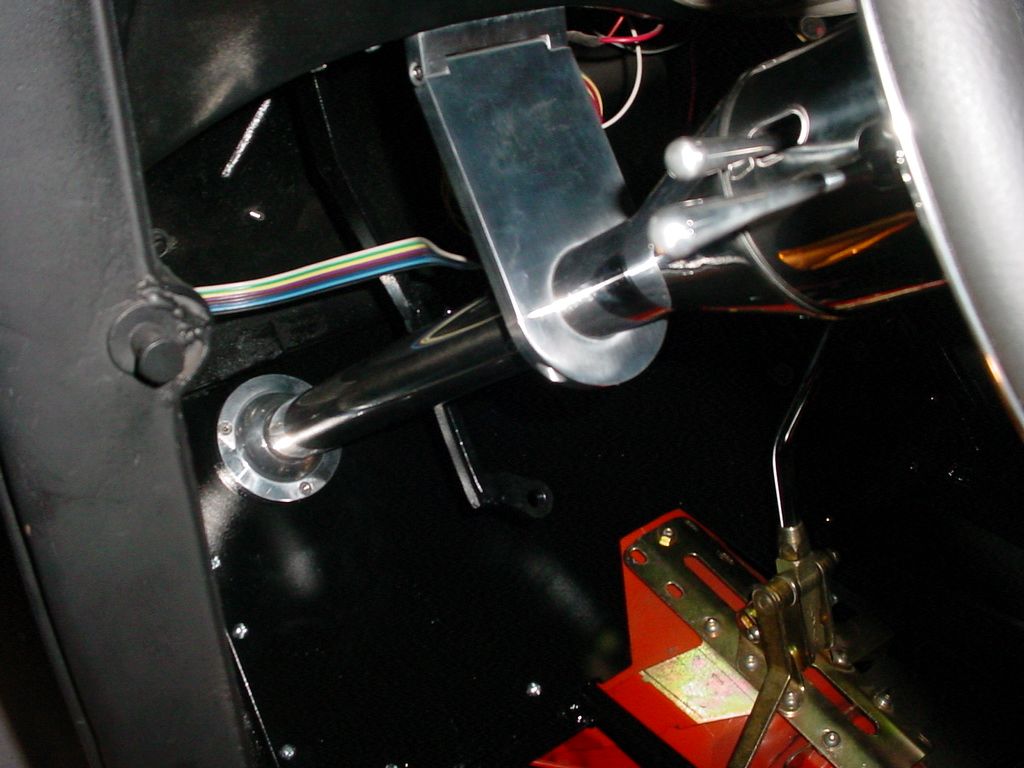

Need to mate up my Flaming River Column and Flaming River manual box. It will be a two joint system. I believe the original setup had the column and box near perfectly inline. I have the new column mocked up with a bit more deflection (up and down @ about 10 degrees). I believe this will be easily managed by the two joints. I did this for 3 reasons. 1) To get the column snug to the opening in the dash. 2) There is no real collapsable component, so the angle could possibly help prevent significant movement of the column into the compartment in case of a collision. 3) To create more room around the headers. The shaft will be about 6" after considering the length of the joints. Total gap from column to box is about 9". 3/4" 36 spline on box and 1" DD on column.

Would like to decide on the shaft type so I can buy and finish mocking everything up before fabing the floor mount.

Thoughts?

Pros, Cons? Tips, Safety?

Need to mate up my Flaming River Column and Flaming River manual box. It will be a two joint system. I believe the original setup had the column and box near perfectly inline. I have the new column mocked up with a bit more deflection (up and down @ about 10 degrees). I believe this will be easily managed by the two joints. I did this for 3 reasons. 1) To get the column snug to the opening in the dash. 2) There is no real collapsable component, so the angle could possibly help prevent significant movement of the column into the compartment in case of a collision. 3) To create more room around the headers. The shaft will be about 6" after considering the length of the joints. Total gap from column to box is about 9". 3/4" 36 spline on box and 1" DD on column.

Would like to decide on the shaft type so I can buy and finish mocking everything up before fabing the floor mount.

Thoughts?