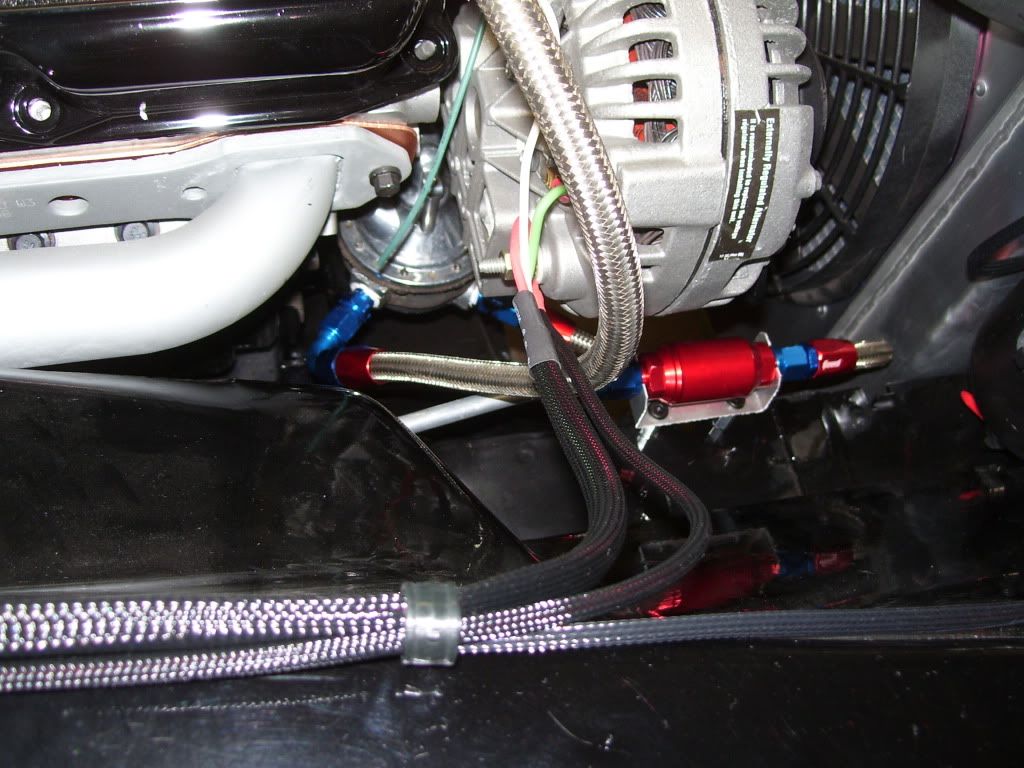

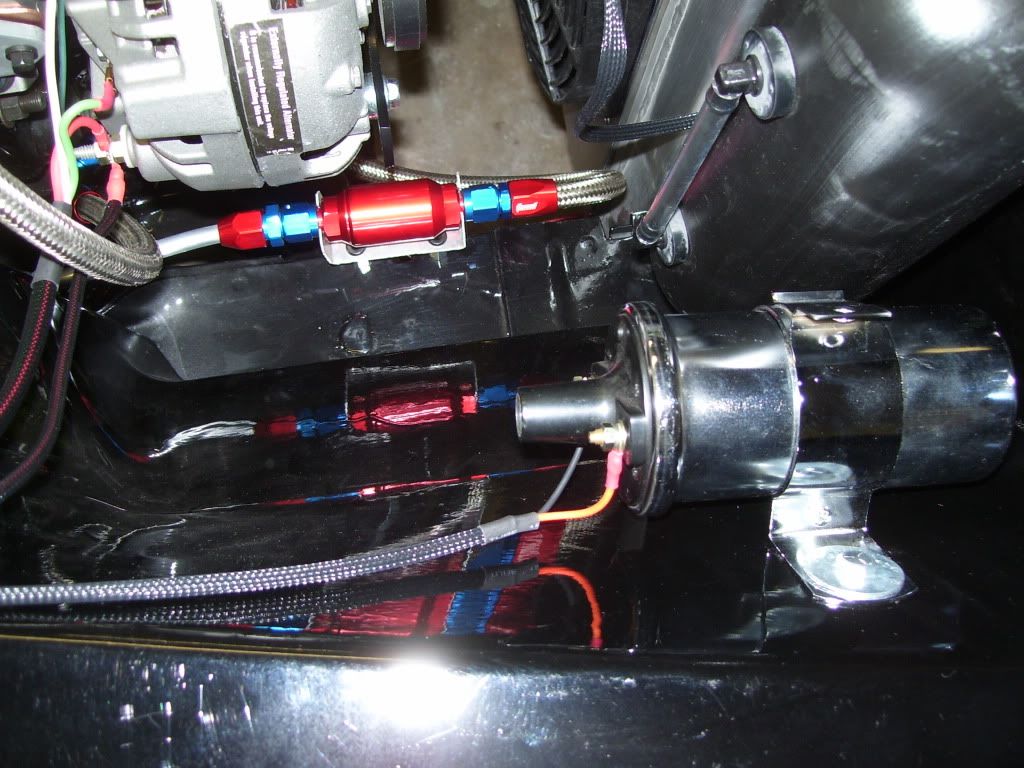

Well, nothing ever turns out like you expect, first thing I did was take my Dart's back tire to the tire shop, because they screwed up when they mounted the tires and f'd up the valve stem, unfortunately they didn't have another, so I had to go to another tire store and buy one, when I got back, I figured I would have them do an alignment on my Ram since I was already waiting. That was a mistake, this must have been his very first, since it took him over two hour, I finally got back around 3:30. But Dennis dropped by and we shot the bull for a few hours, by the time he left, it was time to feed the dogs. Oh well, infigured I was done for the day, but after dinner I got a little froggy and started to wire up the car, by 11:00, I actually made a bit of progress. Tomorrow I will finish up underhood and get started on the dash.