You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What Are You Doing To/With Your Car Today?

- Thread starter MobileCustoms

- Start date

-

MrJLR

Built, not bought

DAMN! That SUCKS.....Took the Dart back to the body shop...

Forgot to pin my hood. Got to 30mph, and the hood pealed off like it was hit by a hurricane..

Damaged the roof too. Nearly 6k in repairs...

Jeff

DAMN! That SUCKS.....

Jeff

YES, it does. Thank you. I cannot describe how I felt when that happened..

I'm very glad to have an awesome Ins. Agent.

MrJLR

Built, not bought

AND.....no one got hurt....that could have been ugly.....YES, it does. Thank you. I cannot describe how I felt when that happened..

I'm very glad to have an awesome Ins. Agent.

Jeff

AND.....no one got hurt....that could have been ugly.....

Jeff

My ego took a pretty good hit. LOL

MrJLR

Built, not bought

I bet.....hey man, it happens.....My ego took a pretty good hit. LOL

rambler440

Member

Went to Spokane Raceway Sunday. Confushish say "When you put big motor in little car with no traction, you make back tires spin like hell" Smart guy! No matter what I did spin like hell! 15 sec. flat. But the speed tells a different story. 105mph hmmm, that should be good for mid-high 13's. First time out in car, guess I know where to begin spending money!

racerhog

RacerHog likes his Mopars

Driving to work.... Ya.... Work..... This sucks.....lol

Quarter patch day here.....

I resurrected a 750HP ..

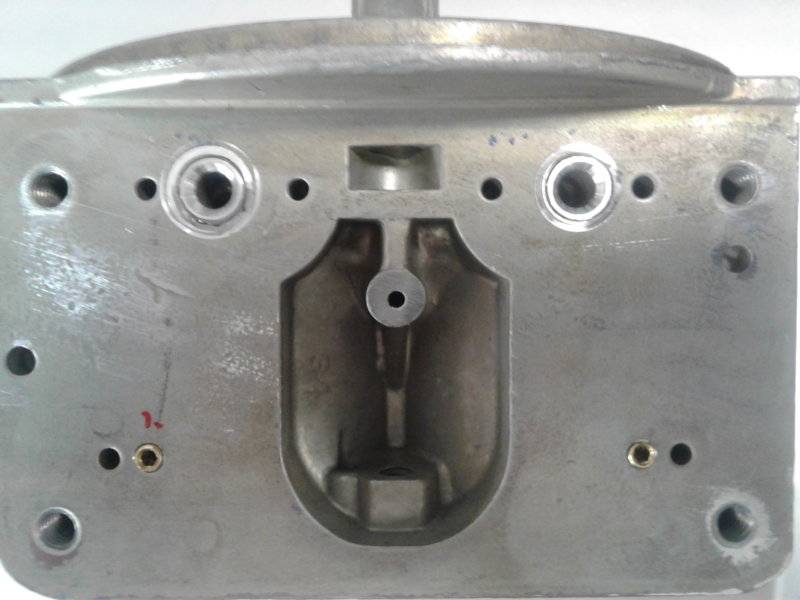

Both shooter threads were stripped out. So I made threaded inserts out of #2 3/8 NF bolts with the 12-28 shooter threads inside.

Then found center, and drilled for the 3/8NF threads..

Once it was drilled, since my table was locked down, I used the chuck to start the threads..

making sure I went just far enough to install the inserts..

once I threaded the ID of the insert, they were ready to install w/ retaining compound..

I did both sides. Hi flow screws will be used in place of the originals.

The original down-leg boosters were generic non-stepped boosters with .382 ID's

These were replaced with AED single stepped down-legs with .438 ID's They flowed a combined 30cfm better than the originals. Booster signal also improved by .33 H20. mostly due to the increased airflow they gave.

Sorry, no pics of the installation procedure. But I will say I don't crimp them in. too hard to get alignment. No bending..

I epoxy them in. it's easier to keep them centered with my special centering fixture and 'bubble' them in place that way.

Then knock them flush with an end mill and chamfer the openings.

.073 T Slot restrictors in place too.

Metering blocks and bowls were in desperate need of refinishing, so I elected to add some color.

After a glass beeding, I mixed a small amount of deep black with generous amount of hardener and shot the parts with an airbrush. shooter diaphragm housings got it too. A Summit dual feed rounded out the look.

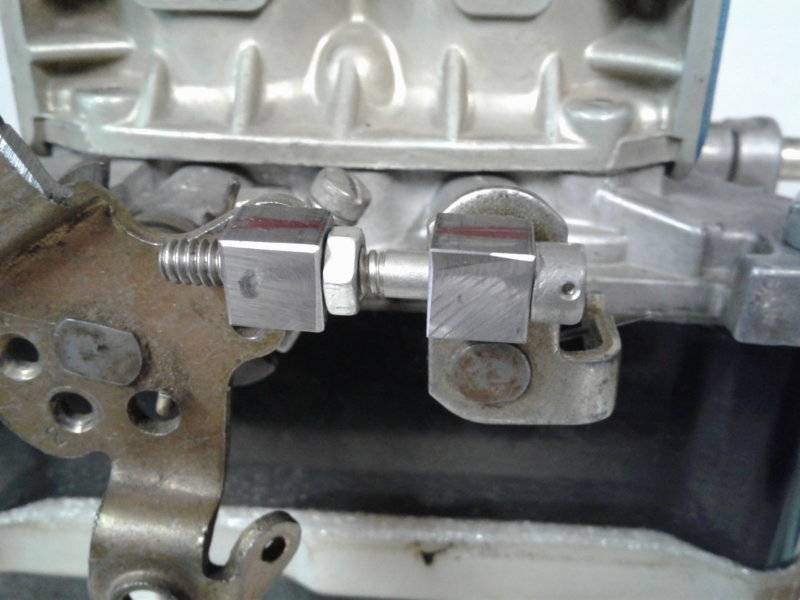

the final touch was the custom secondary link. I found throttle opening angle to be crucial, so I crafted this link that can be adjusted without removing it. (I later beed-blasted that too for a nice finish)

I'm glad I don't have to pay myself to do this stuff...

Both shooter threads were stripped out. So I made threaded inserts out of #2 3/8 NF bolts with the 12-28 shooter threads inside.

Then found center, and drilled for the 3/8NF threads..

Once it was drilled, since my table was locked down, I used the chuck to start the threads..

making sure I went just far enough to install the inserts..

once I threaded the ID of the insert, they were ready to install w/ retaining compound..

I did both sides. Hi flow screws will be used in place of the originals.

The original down-leg boosters were generic non-stepped boosters with .382 ID's

These were replaced with AED single stepped down-legs with .438 ID's They flowed a combined 30cfm better than the originals. Booster signal also improved by .33 H20. mostly due to the increased airflow they gave.

Sorry, no pics of the installation procedure. But I will say I don't crimp them in. too hard to get alignment. No bending..

I epoxy them in. it's easier to keep them centered with my special centering fixture and 'bubble' them in place that way.

Then knock them flush with an end mill and chamfer the openings.

.073 T Slot restrictors in place too.

Metering blocks and bowls were in desperate need of refinishing, so I elected to add some color.

After a glass beeding, I mixed a small amount of deep black with generous amount of hardener and shot the parts with an airbrush. shooter diaphragm housings got it too. A Summit dual feed rounded out the look.

the final touch was the custom secondary link. I found throttle opening angle to be crucial, so I crafted this link that can be adjusted without removing it. (I later beed-blasted that too for a nice finish)

I'm glad I don't have to pay myself to do this stuff...

MrJLR

Built, not bought

Nice work....!I resurrected a 750HP ..

Both shooter threads were stripped out. So I made threaded inserts out of #2 3/8 NF bolts with the 12-28 shooter threads inside.

View attachment 1715223117

Then found center, and drilled for the 3/8NF threads..

View attachment 1715223118

Once it was drilled, since my table was locked down, I used the chuck to start the threads..

making sure I went just far enough to install the inserts..

View attachment 1715223123

once I threaded the ID of the insert, they were ready to install w/ retaining compound..

I did both sides. Hi flow screws will be used in place of the originals.

View attachment 1715223125

The original down-leg boosters were generic non-stepped boosters with .382 ID's

These were replaced with AED single stepped down-legs with .438 ID's They flowed a combined 30cfm better than the originals. Booster signal also improved by .33 H20. mostly due to the increased airflow they gave.

View attachment 1715223128

Sorry, no pics of the installation procedure. But I will say I don't crimp them in. too hard to get alignment. No bending..

I epoxy them in. it's easier to keep them centered with my special centering fixture and 'bubble' them in place that way.

Then knock them flush with an end mill and chamfer the openings.

View attachment 1715223129

.073 T Slot restrictors in place too.

Metering blocks and bowls were in desperate need of refinishing, so I elected to add some color.

After a glass beeding, I mixed a small amount of deep black with generous amount of hardener and shot the parts with an airbrush. shooter diaphragm housings got it too. A Summit dual feed rounded out the look.

View attachment 1715223130

the final touch was the custom secondary link. I found throttle opening angle to be crucial, so I crafted this link that can be adjusted without removing it. (I later beed-blasted that too for a nice finish)

View attachment 1715223132

I'm glad I don't have to pay myself to do this stuff...

Jeff

DesertRat

Leading edge boomer

Bought a digital inclinometer and double checked my pinion angle before installing my new driveline. Added another 1.5 degree of up angle on the pinion to bring the GV tailshaft and the differential pinion to within 1/2 degree. Reinstalled new longer driveling and filled GV with new fluid. Took tires off to take for rebalance just to be sure and tightened up the exhaust headpipes to the manifolds. Finished adding all the correct lubes everywhere and now I am ready to test drive the car. I hope it's clean because with my knees it is a ***** to put it up and down on the stands and I really don't want to have to do it again.

How did you tap the insides of those bolts?

The Castle nut gave me enough threads to hold the inserts and thread onto the end of the bolt.

I bored into the bolt end just far enough for the 'starter' part of the tap to occupy, so that I can get complete threads in the insert.

The end of the bolt is 'squared' so that the insert is held 'square'. I just thread the insert into the nut and lightly 'bind' it in place. Then I just clamped it in the mill vise and used the mill chuck to start the tap accurately, and we're off and running!

MrJLR

Built, not bought

Nice long drive this morning. ...just locally around town, but very nice!

Perfect weather, great tunes....just awesome.

You know you have found the perfect car when you just can't wait to drive it, even when there's nowhere to go!

Never really felt that way about my Stingrays...!

Jeff

Perfect weather, great tunes....just awesome.

You know you have found the perfect car when you just can't wait to drive it, even when there's nowhere to go!

Never really felt that way about my Stingrays...!

Jeff

MileHighDart

Well-Known Member

Let us know how the test drive went. There may be a gearvendors in my future. Would like to know what gears you’re running, tire size and what kind of rpms you’re turning on the highway.Bought a digital inclinometer and double checked my pinion angle before installing my new driveline. Added another 1.5 degree of up angle on the pinion to bring the GV tailshaft and the differential pinion to within 1/2 degree. Reinstalled new longer driveling and filled GV with new fluid. Took tires off to take for rebalance just to be sure and tightened up the exhaust headpipes to the manifolds. Finished adding all the correct lubes everywhere and now I am ready to test drive the car. I hope it's clean because with my knees it is a ***** to put it up and down on the stands and I really don't want to have to do it again.

racerhog

RacerHog likes his Mopars

Bet you get more looks and thumbs up too...Nice long drive this morning. ...just locally around town, but very nice!

Perfect weather, great tunes....just awesome.

You know you have found the perfect car when you just can't wait to drive it, even when there's nowhere to go!

Never really felt that way about my Stingrays...!

Jeff

racerhog

RacerHog likes his Mopars

Just out burning fuel....

no particular place to go - Bing video

no particular place to go - Bing video

MrJLR

Built, not bought

I do.....it's a nice bonus. ....Bet you get more looks and thumbs up too...

Some (most?!) people don't even know what it is. ...but it's got a cool factor that can't be ignored!

Jeff

racerhog

RacerHog likes his Mopars

Dam... That blowsTook the Dart back to the body shop...

Forgot to pin my hood. Got to 30mph, and the hood pealed off like it was hit by a hurricane..

Damaged the roof too. Nearly 6k in repairs...

DesertRat

Leading edge boomer

This could get a bit long---------but-----------74 A-body 8 1/4 shur-grip built by RRP with 3.73:1 gearing. Rebuilt stock leaf suspension. I had an A-999 transmission built for it with Trans-go 2 shift kit and lockup converter. (I didn't want to give up converter slip) I built the car to road trip at 70 MPH at a reasonable RPM. With lockup, 275-60-15 tires and the GV engaged I computer simulated my little 273 would be turning 2400 RPM @ 70 MPH, acceptable to me. I had custom 15" rally wheels built with as much backspace as possible, Cad mockup indicated they would work with no modifications. I had to lower the transmission crossmember about 1.25" and the longer GV tailshaft accentuated the degrees of drop from stock. My first setup I set the pinion angle with an $8 angle finder. On the hunt for the unwanted vibration I bought a digital angle finder and rechecked all my original work. By the GV owners manual checks revealed that the driveline was 3/4" short. I had a new DL built the correct length and installed a positive degree pinion shim of 1.5 degrees. I reassembled all and installed new fluid in the GV. The car runs 2400 RPM @ 70 MPH as calculated. The corrections made to my geometry fixed the vibration issue which never was that bad to begin. We all know harmonic vibration never gets better-only worse. It was a brutal week for this old man but now I can take it to the Olympic Peninsula with confidence.Let us know how the test drive went. There may be a gearvendors in my future. Would like to know what gears you’re running, tire size and what kind of rpms you’re turning on the highway.

Don't ask about my tuning adventures this afternoon.

Last edited:

Just chasing a damn vacuum leak!

Cley

Cley

racerhog

RacerHog likes his Mopars

Today, Out burn up more gasoline....

Hope you found it, they are usualy okay to find on our fine little A-bodies compared to more luxurius cars with an endless amount of vacumlines and actuators under the dashboard for the ventilationsystemJust chasing a damn vacuum leak!

Cley

-

Similar threads

- Replies

- 56

- Views

- 1K