zac_F71

Well-Known Member

Well guys been going hard since the 4th on the car, lots has happened -

Patched the trunk, hung, and fully plumbed the fuel tank

Installed the wideband o2

Replaced the brake prop valve as the rear brakes stopped working

Found a metal on metal grinding sound, tore down the front of the motor, found the crank pulley bolts hitting the timing cover, re-assembled that.. added washers, and milled the inside of the pulley to fit better

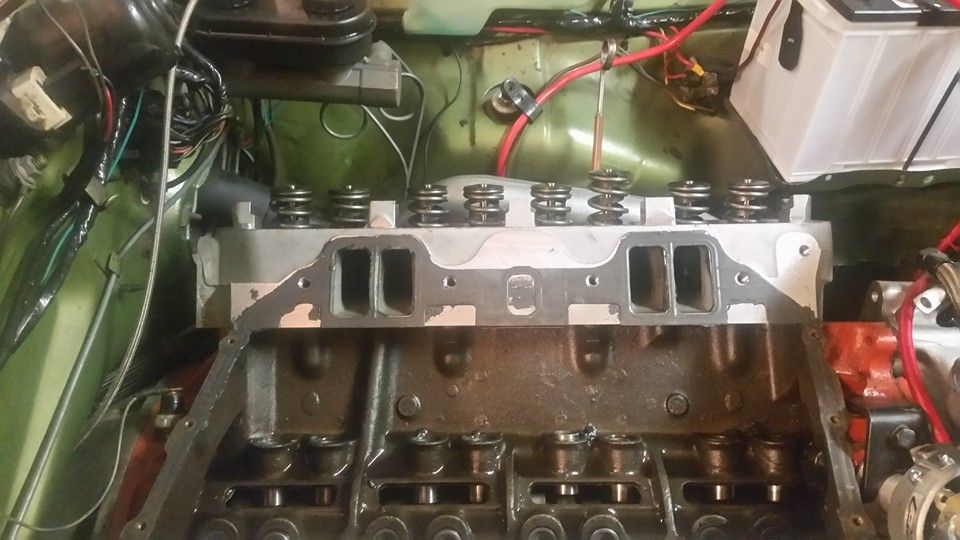

Fired the motor last night had it running for 15-20 minutes, running great, it back fired thru the carb- huge fire ball, died, would not turn over, locked up.. not sure what happened yet but probably not good.. hauling the car home from my friends shop Sunday to tear it apart

Patched the trunk, hung, and fully plumbed the fuel tank

Installed the wideband o2

Replaced the brake prop valve as the rear brakes stopped working

Found a metal on metal grinding sound, tore down the front of the motor, found the crank pulley bolts hitting the timing cover, re-assembled that.. added washers, and milled the inside of the pulley to fit better

Fired the motor last night had it running for 15-20 minutes, running great, it back fired thru the carb- huge fire ball, died, would not turn over, locked up.. not sure what happened yet but probably not good.. hauling the car home from my friends shop Sunday to tear it apart