Wow thank you! We defiantly will!Hit me up when your boy is ready to get VW parts, I work at www.airheadparts.com

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1965 MMP's Barracuda Hemi swap! The Ever Changing Build

- Thread starter MonkeyMadness

- Start date

-

Cudabnu

(3) 64 Val Verts. /6 4spd, 273/904, 318/727

Mods delete if this is not allowed, but I set up a coupon code for any FABO VW enthusiast! Just use code FABO at checkout for 10% off on the above site.. Now back to MOPARS!

So worked briefly on shifter placement. Need to weld in mounting points and mod the shifter housing/ console. Found that B&M makes a truck shifter console that "fits" my needed measurement. B&M-80727 So I bought it and now have to mod it a bit to fit the setup. Should workout with some fine tuning. Shifter is in and working cable sealed and in place. happy with it so far...

Also pulled out the pedal box once again. Need to do a bit more fab work. I'm not happy with the amount of movement/ flex I see with the master cylinder when depressing the pedal. so the box is out and will be adding support bracing to combat the movement.

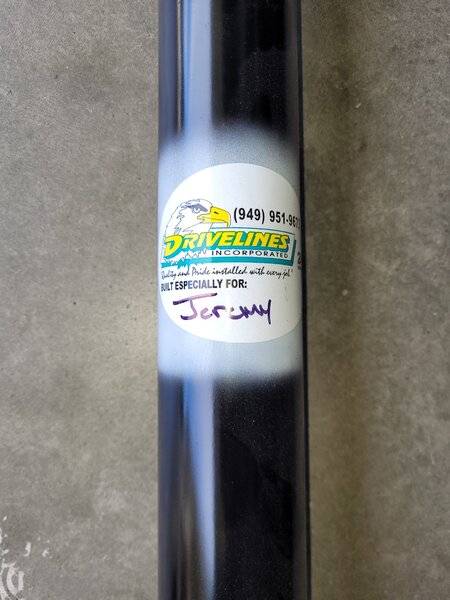

Had a chance to run down to Drivelines inc. and drop off my measurements and transmission driveshaft flange with Wade. I should have it back by the end of the month. The add weight saving from this driveshaft purchase making my wallet much much lighter should help with my Horse Power to Weight ratio...

Also pulled out the pedal box once again. Need to do a bit more fab work. I'm not happy with the amount of movement/ flex I see with the master cylinder when depressing the pedal. so the box is out and will be adding support bracing to combat the movement.

Had a chance to run down to Drivelines inc. and drop off my measurements and transmission driveshaft flange with Wade. I should have it back by the end of the month. The add weight saving from this driveshaft purchase making my wallet much much lighter should help with my Horse Power to Weight ratio...

Last edited:

I've been fiddling around in the garage for a few days now and finally finished the peddle box reinforcement. Now I'm not fond of using angle iron on car projects ( I've now used in on the trans mount, steering support, and the rear end install  ) but I felt I needed the strength and it wouldn't be seen by many. It did the job and it doesn't look too bad at all, I'm happy with it and I have zero booster/firewall flex when depressing the peddle. So I call that a win.

) but I felt I needed the strength and it wouldn't be seen by many. It did the job and it doesn't look too bad at all, I'm happy with it and I have zero booster/firewall flex when depressing the peddle. So I call that a win.

) but I felt I needed the strength and it wouldn't be seen by many. It did the job and it doesn't look too bad at all, I'm happy with it and I have zero booster/firewall flex when depressing the peddle. So I call that a win.

) but I felt I needed the strength and it wouldn't be seen by many. It did the job and it doesn't look too bad at all, I'm happy with it and I have zero booster/firewall flex when depressing the peddle. So I call that a win. I know what you mean about the angle iron. That stuff is supposed to be for tractors and farm equipment, lol. Hey we use what we can when we need it! Looking good!I've been fiddling around in the garage for a few days now and finally finished the peddle box reinforcement. Now I'm not fond of using angle iron on car projects ( I've now used in on the trans mount, steering support, and the rear end install) but I felt I needed the strength and it wouldn't be seen by many. It did the job and it doesn't look too bad at all, I'm happy with it and I have zero booster/firewall flex when depressing the peddle. So I call that a win.

View attachment 1715855980 View attachment 1715855981 View attachment 1715855982 View attachment 1715855983

Did some work on the throttle peddle and placement this weekend. Think it turned out good for the room I had to work with and the firewall mounted fbw throttle.

Last edited:

Nice work as always.Did some work on the throttle peddle and placement this weekend. Think it turned out go for the room I had to work with and the firewall mounted fbw throttle.

View attachment 1715858259 View attachment 1715858260 View attachment 1715858261 View attachment 1715858262 View attachment 1715858263 View attachment 1715858264

So I got my belts, pulleys with front of the motor and all that jazz figured out a while ago. So I was thinking I would start looking for a nice Radiator. I've got a Dakota digital brain box with my dash gauges that run the temp sensor and fan switch and talks to all my elc stuff with magic and mumbo jumbo. So that being said I'm gonna run at least on Elc Fan.

At the moment I'm looking at the Northern Rad #205199 and Shroud #Z40107

Or the Champion Cooling #CC1643-5 Shroud not yet found.

BUT to be honest I would rather "if possible" find and OE style (1965 Era) Big Block rad with intake and return on passenger side that will fit the Early A-body and cool my little hemi...

Got any suggestions?

At the moment I'm looking at the Northern Rad #205199 and Shroud #Z40107

Or the Champion Cooling #CC1643-5 Shroud not yet found.

BUT to be honest I would rather "if possible" find and OE style (1965 Era) Big Block rad with intake and return on passenger side that will fit the Early A-body and cool my little hemi...

Got any suggestions?

Last edited:

- Joined

- Mar 17, 2018

- Messages

- 17,083

- Reaction score

- 41,675

I used a griffin to keep my SRT Hemi cool, I tried desperately to find an OEM one as I was worried about overheating. Finally one old guy at the salvage yard explained to me “ Sonny, don’t nobody wreck these cars backing up” thus the non existent OEM radiators at salvage yards! I too went with a Dakota Digital as I also run that in my race car. Very happy with them but you do need to purchase several Dakota gizmos to make it all work with the modern Hemi.So I got my belts, pulleys with front of the motor and all that jazz figured out a while ago. So I was thinking I would start looking for a nice Radiator. I've got a Dakota digital brain box with my dash gauges that run the temp sensor and fan switch and talks to all my elc stuff with magic and mumbo jumbo. So that being said I'm gonna run at least on Elc Fan.

At the moment I'm looking at the Northern Rad #205199 and Shroud #Z40107

Or the Champion Cooling #CC1643-5 Shroud not yet found.

BUT to be honest I would rather "if possible" find and OE style (1965 Era) Big Block rad with intake and return on passenger side that will fit the Early A-body and cool my little hemi...

Got any suggestions?

Not easy to find a OE radiator I would think. Running a Griffin in mine, single core and even at outside temp last summer at 102* it did good.So I got my belts, pulleys with front of the motor and all that jazz figured out a while ago. So I was thinking I would start looking for a nice Radiator. I've got a Dakota digital brain box with my dash gauges that run the temp sensor and fan switch and talks to all my elc stuff with magic and mumbo jumbo. So that being said I'm gonna run at least on Elc Fan.

At the moment I'm looking at the Northern Rad #205199 and Shroud #Z40107

Or the Champion Cooling #CC1643-5 Shroud not yet found.

BUT to be honest I would rather "if possible" find and OE style (1965 Era) Big Block rad with intake and return on passenger side that will fit the Early A-body and cool my little hemi...

Got any suggestions?

- Joined

- Mar 17, 2018

- Messages

- 17,083

- Reaction score

- 41,675

And PS MM not sure how familiar you are with Dakota Digital but by all means don’t waste a bunch of time and energy trying to sort something out that is not quite right. They have a great customer service group ( tech side) and will stay on the phone with you for troubleshooting etc. just absolutely great customer service on tech side. And they know what they are doing with all the guys doing swaps. No regrets here.

'Cuda_ragtop

Woulda, Shoulda, 'Cuda!

Northern Rad #205199 and Shroud #Z40107

Or the Champion Cooling #CC1643-5 Shroud not yet found.

Got any suggestions?

Those 2 are quite different in size.

Northern Rad #205199 21 3/4 x 21 3/4 x 3 1/8 and Shroud #Z40107

Champion Cooling #CC1643-5 22-5/8" (H) x 29" (W) x 2.75" the core is 26"W, 29"W includes the mounting brackets.

I have the Champion CC1643B for our 69 G3 6.1 Barracuda Fastback.

I ordered it directly from champion but I had them replace the 1.5" inlet with a 1.75" inlet to match the size of the thermostat opening. I figured if it was going to need a 1.75" hose, it might as well fit on both ends. “¯\_(ツ)_/¯“

I also replaced the full radiator core support with US Car Tool's Full Core Support and set it up with the opening to fit the 26" wide Champion Core width.

It is a nice fit.

I am using the Champion PN#1643FS12 Shroud

My fans are 2x Spal 12" 1328 CFM Fans PN#30101522

Seeing your work, you would probably make a better shroud and save money at the same time.

Its just a flat piece of aluminum with a total of (2) 90* bends, one at the top and one at the bottom, 4 mounting holes and 2 fan holes for 12" fans that are smaller than they need to be...

I trimmed some of the narrow top and bottom off to move it about 1/8" closer to the radiator core.

I also opened up to holes on mine to 12" to fit the fans better.

The holes were closer to 11" when I got it...

For mounting the shroud, I cut slots to allow hex head 1/4"-20 bolts to slide into the radiator face, where the shroud mounts. You can see the (4) 1/4-20 bolts pointing away from the radiator through the shroud. Same 1/4-20 stainless bolts and washers mount the fans, held together with stainless nylock nuts.

We are running a ZF 8HP70 8-speed, so we will be connecting the transmission to the included built in trans cooler.

All in, it seems to be a nice setup. I'm getting used to almost everything needing a little refinement so I don't make to much fuss about having to make it "Just Right" for me...

Sorry, I can't tell you how well it cools but I have heard from others that it works for them.

I was originally going to try a single 16" fan but it was 1600 CFM and the 12" Spal fans are 1328 + 1328 or 2656 CFM combined. Will set them up for 1 or 1+1 based on demand.

Oh, and the 12" fans have more clearance from the front of the engine than the singe 16" in our car, by a couple inches. I like that a lot more too.

It's sitting in my office right now, as I have been working on it and test fitting it all together before I paint it all black.

This is my Radiator except I had them change the inlet to 1.75"

This is the shroud.

I too went with a Dakota Digital as I also run that in my race car. Very happy with them but you do need to purchase several Dakota gizmos to make it all work with the modern Hemi.

And PS MM not sure how familiar you are with Dakota Digital but by all means don’t waste a bunch of time and energy trying to sort something out that is not quite right. They have a great customer service group ( tech side) and will stay on the phone with you for troubleshooting etc. just absolutely great customer service on tech side. And they know what they are doing with all the guys doing swaps. No regrets here.

Sublime Thank you. I have the Pleasure of our company's working together in the industry we're in, and I'm long time friends with Josh @DD brothers from another motha... We attend trade shows and event Rides offend together throughout the year(s). BUT! Thanks to you I'll be more than DAMN SURE to Wake his *** up a 3am to relay the Good Customer Feed back from the FABO board haha!

Those 2 are quite different in size.

Northern Rad #205199 21 3/4 x 21 3/4 x 3 1/8 and Shroud #Z40107

Champion Cooling #CC1643-5 22-5/8" (H) x 29" (W) x 2.75" the core is 26"W, 29"W includes the mounting brackets.

I have the Champion CC1643B for our 69 G3 6.1 Barracuda Fastback.

I ordered it directly from champion but I had them replace the 1.5" inlet with a 1.75" inlet to match the size of the thermostat opening. I figured if it was going to need a 1.75" hose, it might as well fit on both ends. “¯\_(ツ)_/¯“

I also replaced the full radiator core support with US Car Tool's Full Core Support and set it up with the opening to fit the 26" wide Champion Core width.

It is a nice fit.

I am using the Champion PN#1643FS12 Shroud

My fans are 2x Spal 12" 1328 CFM Fans PN#30101522

Seeing your work, you would probably make a better shroud and save money at the same time.

Its just a flat piece of aluminum with a total of (2) 90* bends, one at the top and one at the bottom, 4 mounting holes and 2 fan holes for 12" fans that are smaller than they need to be...

I trimmed some of the narrow top and bottom off to move it about 1/8" closer to the radiator core.

I also opened up to holes on mine to 12" to fit the fans better.

The holes were closer to 11" when I got it...

For mounting the shroud, I cut slots to allow hex head 1/4"-20 bolts to slide into the radiator face, where the shroud mounts. You can see the (4) 1/4-20 bolts pointing away from the radiator through the shroud. Same 1/4-20 stainless bolts and washers mount the fans, held together with stainless nylock nuts.

We are running a ZF 8HP70 8-speed, so we will be connecting the transmission to the included built in trans cooler.

All in, it seems to be a nice setup. I'm getting used to almost everything needing a little refinement so I don't make to much fuss about having to make it "Just Right" for me...

Sorry, I can't tell you how well it cools but I have heard from others that it works for them.

I was originally going to try a single 16" fan but it was 1600 CFM and the 12" Spal fans are 1328 + 1328 or 2656 CFM combined. Will set them up for 1 or 1+1 based on demand.

Oh, and the 12" fans have more clearance from the front of the engine than the singe 16" in our car, by a couple inches. I like that a lot more too.

It's sitting in my office right now, as I have been working on it and test fitting it all together before I paint it all black.

View attachment 1715859053

This is my Radiator except I had them change the inlet to 1.75"

View attachment 1715859058

This is the shroud.

View attachment 1715859076

All Good info this is why I asked thank you!

So I got the driveshaft yesterday. Got it installed and everything fits.

This "Build Back Better" **** sucks! 4 1/2 months on back order through Summit and now kicked back to 4/27. Ended up finding on the shelf at some eBay store of all places. Worse parts is the lokar stuff is cheap and low quality, dare I say "Chinese"? Pretty upset with it BUT it looks like it will sever its purpose for now. till I find a better alternative

Last edited:

85* degrees Yesterday! So I played out side all day! Pushed the car out to get some sun while I cleaned the garage and got it prepped to nose the car in. I'm going to rip the rear end back out and clean up some stuff, install the fuel lines and rear brake lines Battery box and cable. Thought I would get the back end of the car buttoned up first before starting on the interior and underdash harness.

I do need some help finding the Sail panel insulation/fiber board? I've only been able to find 1 kit for sale and they want like $122 for the crap...

I do need some help finding the Sail panel insulation/fiber board? I've only been able to find 1 kit for sale and they want like $122 for the crap...

Lots of fun happening in that driveway today!

Cley

Cley

With regard to your angle iron, only you and the 10,000 of us reading this forum will know!I've been fiddling around in the garage for a few days now and finally finished the peddle box reinforcement. Now I'm not fond of using angle iron on car projects ( I've now used in on the trans mount, steering support, and the rear end install) but I felt I needed the strength and it wouldn't be seen by many. It did the job and it doesn't look too bad at all, I'm happy with it and I have zero booster/firewall flex when depressing the peddle. So I call that a win.

View attachment 1715855980 View attachment 1715855981 View attachment 1715855982 View attachment 1715855983

Last edited:

Harpo

Member

Just started following your build - absolutely Amazing! I'm doing a '64 Cuda/Gen 3/TKO600 swap. I currently have almost all the QA1 K-member, upper/lower control arms installed, and am curious whose rack & pinion did you use? I know I'll need to switch spindles (whose did you use?)

Hello! Everything I used for the front end was part of the HDK kit I got from HemiDenny /@HemiDenny. The spindles and brakes are Mustang II bits.Just started following your build - absolutely Amazing! I'm doing a '64 Cuda/Gen 3/TKO600 swap. I currently have almost all the QA1 K-member, upper/lower control arms installed, and am curious whose rack & pinion did you use? I know I'll need to switch spindles (whose did you use?)

-So I've been putting it off since I got the car back cause i was afraid of what I would find. When the car was loaded on the flatbed to come home I happened to get a glimpse of the rear end and then when I installed the drive shaft got a bit closer and notice the brakes seals were rotted and peeling back from the caliper... ugh So this weekend i finally pulled the rear end out and sure enough it dirty and just not as nice as when i sent it. You can tell to spent some (alot) time out side behind the paint shop. I expected it I mean paint and bodys shops are not the cleanest of places. I also pulled the tank to check the interior contents to make sure nothing got in side, it was fine. While the rear ends out I'm going to run the fuel lines and the rear brake lines. before reinstalling the rear end. I also installed my tail light harness (After hanging it from my garage rafters for a few weeks to get that extra few inches I needed) Cool trick I learned from an "OLD" Chopper builder back in the day-- it fit perfectly! I also installed the door handles and key lock on both doors and trunk!

I'll post up more picture this week..

So I ordered The rebuild kit for the Brakes and a few fitting bits and the fuel filler body gasket now just waiting on them.

I'll finish up the fuel line this week and ge the tank back in. I have to finish running the fuel pump hot lead and ground as well as the sender unit leads. Also thinking and depending on if I get the parts I need to finish the rear end. I may pull the dash out and start putting that together. Have to figure out how I'm going to splice all FIVE harness together and remove the unused bits with out driving myself batty.

-The Dakota Digital to Bouchillon/Hotwire harness will be easy peasy. Its the Dash harness I'm worried about should be a pain in the ***. The under hood harness I'm hoping will be just a removal of the engine wiring and leaving the head light/blinker harness. The rear body harness should just be splicing in 3 wire soo not too worried about that!

I'll finish up the fuel line this week and ge the tank back in. I have to finish running the fuel pump hot lead and ground as well as the sender unit leads. Also thinking and depending on if I get the parts I need to finish the rear end. I may pull the dash out and start putting that together. Have to figure out how I'm going to splice all FIVE harness together and remove the unused bits with out driving myself batty.

-The Dakota Digital to Bouchillon/Hotwire harness will be easy peasy. Its the Dash harness I'm worried about should be a pain in the ***. The under hood harness I'm hoping will be just a removal of the engine wiring and leaving the head light/blinker harness. The rear body harness should just be splicing in 3 wire soo not too worried about that!

So cleaned a spot on the frame to mount the corvette style fuel filter/ pressure regulator, but didn't want to us a sheet metal or self tapping style screw to mount it just in case I have to remove it or replace it at any time so I barrowed a Riv-nut installer and a riv-nut. This thing worked awesome, I need one of these damn things soo easy...

rapidtransitric

LX/LC platform a body swap pioneer

Amazing with the right tool!

Also been looking into height adjustable rear coilovers for the IRS setup. I'm thinking I may!?! want to drop the rear end a bit. I want the car to appear lower more of a performance stance rather than stink bug..

-

Similar threads

- Replies

- 2

- Views

- 109

- Replies

- 1

- Views

- 77

- Replies

- 1

- Views

- 80

- Replies

- 13

- Views

- 304

- Replies

- 2

- Views

- 110