Getting closer!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1972 Duster Build with my Daughter

- Thread starter Jim Kueneman

- Start date

-

Dave made a bit more progress.

Damn another rainy day in the desert.... This is getting old.... what to do today?

Watched a movie on Netflix then decided to work on the dash trim....

First I primed the 3 pieces with SEM primer after the bead blaster and a bit of hand sanding with the scotch pad in the napkin tray.

I then tried two different Krylon "metallic" paints. At the end of the day it does not matter none of them look like chrome.

I then used the 3M pin striping tape to mask off where the chrome areas should be and shot it with SEM Satin Black....

After stripping off the masking tape and applying the DMT wood grain decals it will pass for government work.....

First I primed the 3 pieces with SEM primer after the bead blaster and a bit of hand sanding with the scotch pad in the napkin tray.

I then tried two different Krylon "metallic" paints. At the end of the day it does not matter none of them look like chrome.

I then used the 3M pin striping tape to mask off where the chrome areas should be and shot it with SEM Satin Black....

After stripping off the masking tape and applying the DMT wood grain decals it will pass for government work.....

John_Lemon

Well-Known Member

Superior job Jim, simply superior.

Not to be a party pooper but if you spent as much time on putting it back together as you do documenting every bolt, she would be driving it by now.

Damned engineers.

Not to be a party pooper but if you spent as much time on putting it back together as you do documenting every bolt, she would be driving it by now.

Damned engineers.

Superior job Jim, simply superior.

Not to be a party pooper but if you spent as much time on putting it back together as you do documenting every bolt, she would be driving it by now.

Damned engineers.

Ha but engineers are HORRIBLE at documenting anything! The documentation occurs in the evening with a glass of whisky to try to relax the sore muscles.

txstang84

Well-Known Member

Just saw this build-very nice!

John_Lemon

Well-Known Member

You're too young to get sore.Ha but engineers are HORRIBLE at documenting anything! The documentation occurs in the evening with a glass of whisky to try to relax the sore muscles.

Rolling time! Too bad I’m in the Ozarks working on my day off we can’t pick it up till next week

Finally home. Bob at Glenray has the heater core and said it would only take him a few days. I need to suck it up and order the dash harness ($$$$) this weekend so we can get the dash done. I got the speedo back from Dicks in Tempe and it looks and seems to work perfectly. This weekend will be restore the AC side of the box and finish up the dash face plus make sure we are ready for the engine to just start slapping on accessories!

@Kaelyn says she like it the way it is so we are going to just shoot it with clear and call it done. I will try my best to be supportive.... I want it all blue.....

John_Lemon

Well-Known Member

Looking good.

Have you picked headers yet?

Have you picked headers yet?

Looking good.

Have you picked headers yet?

Stock manifold, I really dislike headers for many reasons.

Last edited:

Cold morning but turned out to be a nice day. The main thing holding us up is the heater box. Bob (Glenray) has the heater core and should turn it around in a few days. We rebuilt what we could and are ready to just slap it in and bolt it together. Remember this is a 1973 AC system in the '72.

We ripped it apart a while ago to get the heater core out. Today we hooked up the pressure washer and simple green/orange paint stripper'ed it to clean it up and scrapped off the old dried out foam seals. We then bead blasted the doors and painted them up so they won't rust again. The condenser had no signs of leaking so we flushed it out with SPI 700 wax and grease remover (water based and dried without a film), bead blasted and painted it with Seymours stainless steel.

Now the fun part. Detroit Muscle Technologies kit is all you need.....

Slip the condenser in to the housing and line up the foam seal you just installed.

Install the blower resistor (after bead blasting and cleaning). Also I put some dum-dum (3M strip caulk) in the bottom channel. The DMT kit did not mention it but this one had it from the factory.

The condenser is held in with 2 screws and the channel in the bottom.

We ripped it apart a while ago to get the heater core out. Today we hooked up the pressure washer and simple green/orange paint stripper'ed it to clean it up and scrapped off the old dried out foam seals. We then bead blasted the doors and painted them up so they won't rust again. The condenser had no signs of leaking so we flushed it out with SPI 700 wax and grease remover (water based and dried without a film), bead blasted and painted it with Seymours stainless steel.

Now the fun part. Detroit Muscle Technologies kit is all you need.....

Slip the condenser in to the housing and line up the foam seal you just installed.

Install the blower resistor (after bead blasting and cleaning). Also I put some dum-dum (3M strip caulk) in the bottom channel. The DMT kit did not mention it but this one had it from the factory.

The condenser is held in with 2 screws and the channel in the bottom.

Last edited:

The one is on the out side of the box.

According the the DMT instructions only '73 had the freeze up switch, not sure why, seems like a great idea...

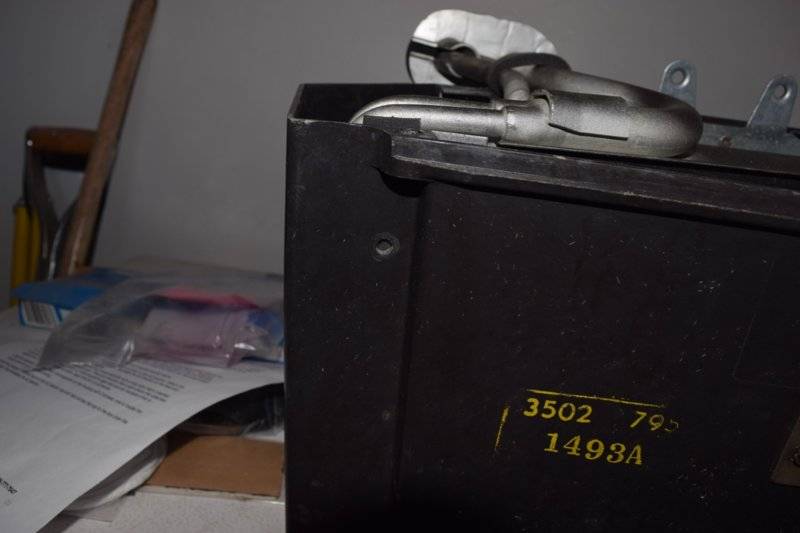

To test mine it was in the freezer since we started. If it senses freeze up it opens and shuts off the compressor.

Yup, open circuit when we took it out of the freezer. Held the probes one to see what happens as it warmed up..

There was an audible click after a minute or two and yup short circuit, compressor would have come back on.

Here is the alien probing into the core. There is a hole down the fins between the tubes where this probe is inserted.

DMT gives you the necessary gasket for the one year only switch

New foam on the fresh air damper, make sure the probe is out of the way so it will open all the way.

Make sure you use the short bolt in this corner. The shape of the box requires this to be a short bolt.

Resistor installed.

According the the DMT instructions only '73 had the freeze up switch, not sure why, seems like a great idea...

To test mine it was in the freezer since we started. If it senses freeze up it opens and shuts off the compressor.

Yup, open circuit when we took it out of the freezer. Held the probes one to see what happens as it warmed up..

There was an audible click after a minute or two and yup short circuit, compressor would have come back on.

Here is the alien probing into the core. There is a hole down the fins between the tubes where this probe is inserted.

DMT gives you the necessary gasket for the one year only switch

New foam on the fresh air damper, make sure the probe is out of the way so it will open all the way.

Make sure you use the short bolt in this corner. The shape of the box requires this to be a short bolt.

Resistor installed.

Last edited:

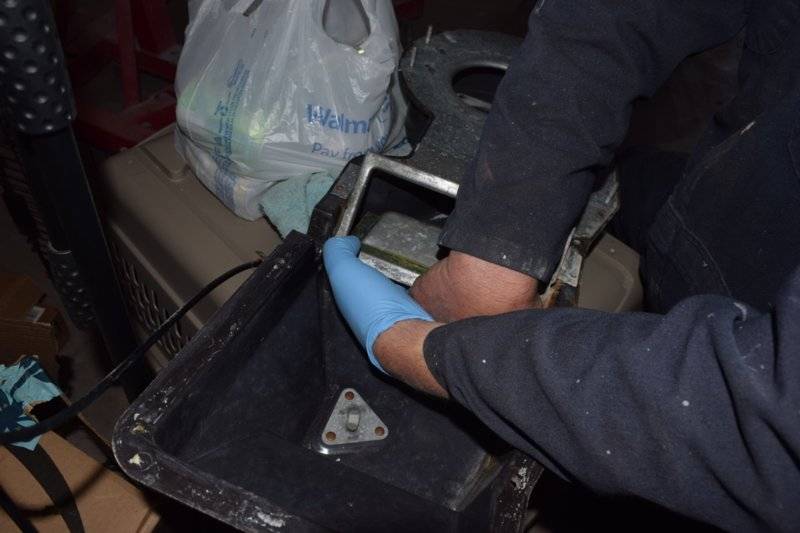

Bead blasted the actuator and tested it. Just hold your finger over one of the nipples and pull/push on the rod. If the diaphragm is leaking it will not hold and slowly move to the other postions.

The hot/cold blend door does not come out unless you drill out a lot of rivets. The DMT instructions say to do it in place. It is a bear. I used my finger to get the glue where I needed it

Yes a new foam piece goes on the back side of this door....

The floor heater foam is balanced on the edge of the plastic. A bit tricky but not too bad.

Installed the bolts gaskets.

Then glue in the insulation and blower motor/drain tube gaskets.

Here is how that blind door turned out. Not great but functional.

All these parts are ready for the core to come and drop in. Just need to bolt it in and screw the box together, all the foam seals are glued in and ready to assemble.

The hot/cold blend door does not come out unless you drill out a lot of rivets. The DMT instructions say to do it in place. It is a bear. I used my finger to get the glue where I needed it

Yes a new foam piece goes on the back side of this door....

The floor heater foam is balanced on the edge of the plastic. A bit tricky but not too bad.

Installed the bolts gaskets.

Then glue in the insulation and blower motor/drain tube gaskets.

Here is how that blind door turned out. Not great but functional.

All these parts are ready for the core to come and drop in. Just need to bolt it in and screw the box together, all the foam seals are glued in and ready to assemble.

Had the compressor clutch bearing in the freezer next to the peas since yesterday. Put the clutch housing in the toaster over and then sent it home...

I used the old bearing as a driver. Once it is below the surface start the snap ring and then use the old bearing to drive the snap ring and bearing down a bit more until the snap ring engages. If you don't the old bearing will start in the housing and then you will have fun getting it back out.

The clutch can be driven on with a socket. Use some grease on both these surfaces to help a little.

Second snap ring and your done.

Organization time. Here are all the parts left to install, and I thought we were close Completely forgot about the rear bumper brackets... Kaelyn removed them.

Completely forgot about the rear bumper brackets... Kaelyn removed them.

Above all started because I was looking for the compressor bolts. They were the only thing we could not find. After hours of searching and swearing I found them in the container where all my leftover Coronet parts are..... I must have grabbed that bag somehow the last time I was going through the Coronet parts and tossed them in there.... Sigh...

The clutch get ground through the housing so make sure the metal is bare where it bolts together.

The wire entry point can be fragile. I used a bit of plasti-dip so strengthen it.

Yes we know the coil has to come back off because the mounting bolts go through the front as does the main bracket but we looked so hard for these bolts were were going to use the damn things.

I used the old bearing as a driver. Once it is below the surface start the snap ring and then use the old bearing to drive the snap ring and bearing down a bit more until the snap ring engages. If you don't the old bearing will start in the housing and then you will have fun getting it back out.

The clutch can be driven on with a socket. Use some grease on both these surfaces to help a little.

Second snap ring and your done.

Organization time. Here are all the parts left to install, and I thought we were close

Above all started because I was looking for the compressor bolts. They were the only thing we could not find. After hours of searching and swearing I found them in the container where all my leftover Coronet parts are..... I must have grabbed that bag somehow the last time I was going through the Coronet parts and tossed them in there.... Sigh...

The clutch get ground through the housing so make sure the metal is bare where it bolts together.

The wire entry point can be fragile. I used a bit of plasti-dip so strengthen it.

Yes we know the coil has to come back off because the mounting bolts go through the front as does the main bracket but we looked so hard for these bolts were were going to use the damn things.

Last edited:

We are staged for the arrival of the 318! It should just be an elbows and butts slapping parts on!

Here is what is left. Bottom shelf is all that is left to restore.

Here is what is left. Bottom shelf is all that is left to restore.

Gonna take a few more whiskeys before I can bring myself to pushing "order" from Classic for the dash harness. The rest of the harnesses are reasonable but the $500 tag for the dash harness kills me but it is a necessity......

sireland67

Well-Known Member

$500 for wiring is cheaper than a dash fire would be.

$500 for wiring is cheaper than a dash fire would be.

My argument EXACTLY! It still hurts

Jameson helped me through it's ordered along with 20 other parts..... The next painful projects are the seats at Baca and the bumper rechroming.... oh and tires/rims and exhaust....My argument EXACTLY! It still hurts

Are you firing up and driving come March? Great project very methodical made it look easy! Love the different color and that you kept it!

April is the plan.

-

Similar threads

- Replies

- 1

- Views

- 630

- Replies

- 5

- Views

- 3K

- Replies

- 204

- Views

- 32K