In the mountains with the Coronet for a show this weekend, which she won several things and will be on the tee shirts next year! The show got the daughter excited and even after 5 hours traveling back home she wanted to spend time in the garage. No photos but the K frame and power train is ready to drop onto the dollies now. More photos coming....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1972 Duster Build with my Daughter

- Thread starter Jim Kueneman

- Start date

-

Finding quality time to work in the garage is at a premium since we got the Duster/Dart Parts Car. We spent a few hours today and made some serious progress! Drivetrain out, front suspension pull completely apart ready for blasting and rebuilding and everything is bagged and tagged. Should have the motor stripped down tomorrow night. May drop it off at the machine shop Friday....

More documentation of the Dart power train and under the hood. We should have the Sandblasting station up and running this weekend to give her something to do during the day while I am at work over the summer.

Last edited:

Two nights in a row! We have it almostly tore down. The engine was not immaculately maintained but it was not bad. The valves and cylinders look good, no burnt valves or scored cylinders. Was hoping to get it to the machine shop tomorrow but we won't have time to work on it. I will be getting the sandblasting station setup and some castors on the Dart so we can roll it out of the garage today while she spends the day with a friend. The plans in the next weeks are:

- Take the engine to the machine shop

- Buy my Wiseco Pistons I found that a guy bought and never used.

- Take the UCA and LCA to the machine shop to get the bushings replaced.

- Order my ported stage 2 Toth Performance Street Fighter aluminum heads

- Send the steering gear to Firm Feel for a stage 2 upgrade

- Drop the transmission off at the shop for a rebuild

- I called Bob at GlenRay radiator and we have a plan and he will be looking for 26" A body radiator tanks at shows this summer to build me a radiator

- Send the speedometer to Dicks Speed-O-Tach in Tempe to get the bushing repaired and calibrated as we restore the cluster

- Tear down the AC compressor/Starter/PS Pump/Alternator and decide if they are worth rebuilding and if so rebuild them

- Rebuild the Chrysler front disk calipers

- Order all new front end parts and install (ball joints/tie rod ends/idler arm/pitman arm)

- Have the daughter sandblast the parts we removed and get them painted with SPI epoxy primer and correct'ish colors for the "restoration"

Last edited:

I learned with the Coronet, these brackets look simple but 2 months from now they are a maze....

Old 318 does not look too bad for being 46 years old.

moparmat2000

Well-Known Member

Cool project. Nice to see your daughter interested in this stuff. This will make memories for both of you for a lifetime

72 duster horizontal holes are for heater core. 67-72 uses the same heater core PN# for a/c cars and non a/c cars. .

BTW, If you decide on not using the under dash part of the A/C from the donor, vintage air make that part as custom fit for A bodies.

72 duster horizontal holes are for heater core. 67-72 uses the same heater core PN# for a/c cars and non a/c cars. .

BTW, If you decide on not using the under dash part of the A/C from the donor, vintage air make that part as custom fit for A bodies.

moparmat2000

Well-Known Member

I looked into the custom fit setup for in dash. Unit mounts to firewall of 67-72 with existing holes. They give you 4 rectangle vents. If this is the one i am thinking of, you modify the oem non A/C heat defrost temp slider lever to add in a switch on the back side. So everythings in the dash using stock heater slider controls. You prob have to slide the lever to full cold to close the switch and make the compresor run, uses the stocker 3 speed fan switch in the dash, and of course the sliding lever that goes from floor air to defog now runs to the new under dash unit. I believe in the middle setting it now becomes dash air. I want one of these for my 67 cuda.

Thanks! I am on the fence. The guy has a ton of AC boxes laying around is back yard. I really like the looks and durability of the factory system but don’t want to spend years finding all the parts either.I looked into the custom fit setup for in dash. Unit mounts to firewall of 67-72 with existing holes. They give you 4 rectangle vents. If this is the one i am thinking of, you modify the oem non A/C heat defrost temp slider lever to add in a switch on the back side. So everythings in the dash using stock heater slider controls. You prob have to slide the lever to full cold to close the switch and make the compresor run, uses the stocker 3 speed fan switch in the dash, and of course the sliding lever that goes from floor air to defog now runs to the new under dash unit. I believe in the middle setting it now becomes dash air. I want one of these for my 67 cuda.

I looked into the custom fit setup for in dash. Unit mounts to firewall of 67-72 with existing holes. They give you 4 rectangle vents. If this is the one i am thinking of, you modify the oem non A/C heat defrost temp slider lever to add in a switch on the back side. So everythings in the dash using stock heater slider controls. You prob have to slide the lever to full cold to close the switch and make the compresor run, uses the stocker 3 speed fan switch in the dash, and of course the sliding lever that goes from floor air to defog now runs to the new under dash unit. I believe in the middle setting it now becomes dash air. I want one of these for my 67 cuda.

Will their system work with the old RV2 compressor?

Last edited:

moparmat2000

Well-Known Member

Probably. Will need to mod the lines to fit at the firewall end. Both A/C and both water lines will come out at old blower motor hole with this. Old water line holes get plugged w caplugs.

I believe a cable for inner fender mount water shutoff valve, and a wire for compressor, and low pressure switch also comes out of the old water line firewall holes.

I believe a cable for inner fender mount water shutoff valve, and a wire for compressor, and low pressure switch also comes out of the old water line firewall holes.

Last edited:

Budget underhood AC retrofit.

Check out my thread on using factory in dash stuff with modern under hood parts. All the research is done. I have been using it for a few weeks now and am very happy

Cley

Check out my thread on using factory in dash stuff with modern under hood parts. All the research is done. I have been using it for a few weeks now and am very happy

Cley

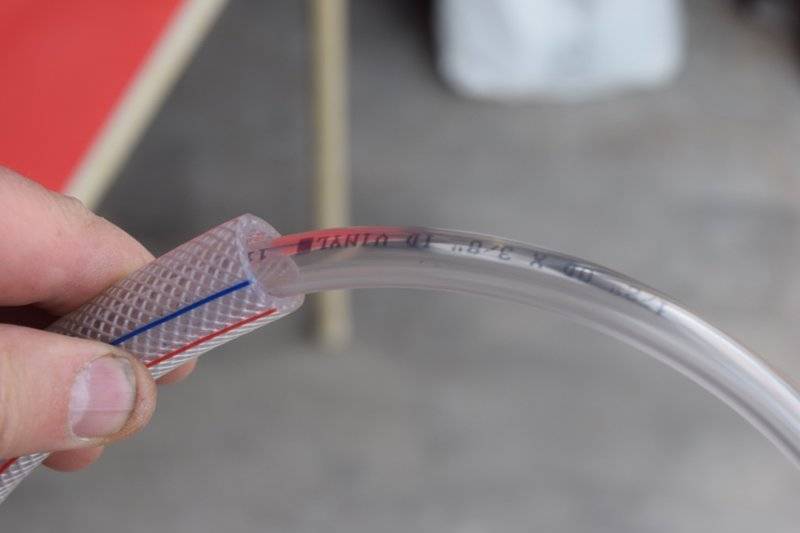

Ok called FirmFeel and the Stage II gear is ordered. Great guys to deal with.... Sale and coupon at Harbor Freight so I stopped by and bought a few things. It works great except the flimsy hose that pulls the media up gets kinked and collapses under the suction. I pushed a stiffer hose from the hardware store down its guts, it lowers the amount of media that can flow but won't kink now. I got one exhaust manifold done while learning the ins and outs of using it. I hope she is not too mad at me for working on her car with her not home.... The next thing is to get a cheap light inside. You can't see a damn thing. This will give the daughter something to do during the week when I am at work....

Last edited:

Started the morning thinking about the blasting cabinet. The film they put on the glass had a leak in it so the dust was getting between the glass and film so it was impossible to see into it after a while. I took the glass out and put on a new one (they gave you 2 in the box) and made sure everything was sealed very well. I think I may just get a half dozen 1'x2' pieces of cheap glass and not use the film, it really makes it hard to see in the box. I have not put it back in as I plan to install some lights.

Kaelyn came home from staying with a friend overnight and we got busy pull the rest of the power train down...

Kaelyn came home from staying with a friend overnight and we got busy pull the rest of the power train down...

Everything is pulled down, documented and bagged and tagged...

The summer storms are starting so we barely got all the items we removed stripped with a gallon of Aircraft Stripper and a power washer before we had to call it a day. I think the trade for $50 of stripper for the much reduced time of sand blasting is worth it to me. These parts are almost stripped of paint and grime now.

And one exhaust manifold is sand blasted.

The summer storms are starting so we barely got all the items we removed stripped with a gallon of Aircraft Stripper and a power washer before we had to call it a day. I think the trade for $50 of stripper for the much reduced time of sand blasting is worth it to me. These parts are almost stripped of paint and grime now.

And one exhaust manifold is sand blasted.

JayinMI

Well-Known Member

I clicked on a Youtube video review of that blasting cabinet...which led me to find several videos about mods to make to it. Apparently, lighting isn't it's only weak spot, but it's a good start. If I had more room and a better compressor I'd pick one up.

Nice progress.

Jay

Nice progress.

Jay

I clicked on a Youtube video review of that blasting cabinet...which led me to find several videos about mods to make to it. Apparently, lighting isn't it's only weak spot, but it's a good start. If I had more room and a better compressor I'd pick one up.

Nice progress.

Jay

Yea, $100 does not get you much.... even from China!

SLOPAR72

Well-Known Member

I clicked on a Youtube video review of that blasting cabinet...which led me to find several videos about mods to make to it. Apparently, lighting isn't it's only weak spot, but it's a good start. If I had more room and a better compressor I'd pick one up.

Nice progress.

Jay

I have one and it just hasn't made it's way to recycling yet..... I have a huge TP cabinet but is still in my dad's garage and got a HF off Clist to do small things at home. For you guys doing restoration work at the type of level in this thread a quality cabinet is worth it's weight in gold...

Nice progress BTW Jim....

JW

Ok 24 feet of LED string lights and the box is like daylight with no shadows! I liked this idea because the string are 100% sealed and it works great! The camera and the red box make the bulb look red. I person they are bright white.

The daughter is fully up to speed on the safety and usage of blasting and she spent an hour practicing this afternoon and got a couple of parts done. She has a pile for the week since it is summer vacation! While she was getting the hang of blasting I used my $18 HF pulley puller I bought today and got the pulleys off the Federal pump and Alternator. The pump is clearly original and the alternator is off a '76 something or other but I think it is a Chrysler part.... the metal seems a strange color and finish to me.....

The daughter is fully up to speed on the safety and usage of blasting and she spent an hour practicing this afternoon and got a couple of parts done. She has a pile for the week since it is summer vacation! While she was getting the hang of blasting I used my $18 HF pulley puller I bought today and got the pulleys off the Federal pump and Alternator. The pump is clearly original and the alternator is off a '76 something or other but I think it is a Chrysler part.... the metal seems a strange color and finish to me.....

Paladin06

Well-Known Member

View attachment 1715186031 That’s awesome. Started mine for my daughter back in 2007. Here it is today.

Maybe we will all meet someday at the Hemi Show!

moparmat2000

Well-Known Member

My brother got the HF blaster. I am going to get one for myself too. He bought a "bucket head" from home depot. It is a shop vac top that fits a 5 gallon spackle bucket. Said it works great. He also mounted his blaster and bucket head to a frame with castors so he could move it around the shop or use it outside

moparmat2000

Well-Known Member

That K frame, id get a big enough plastic trash can w lid to submerge it completely, and mix up feed grade molasses and water 9 parts water to 1 part molasses to fill that can up. Attach wires to it, and submerge it in the molasses for about a weekbor 2, then hit it with a pressure washer, it will be clean as a whistle. With nice bare metal

Then before it has a chance to dry and flash rust, spray it down with tri sodium phosphate and water solution. You can get the TSP in powder form in paint dept at lowes or home depot.

Then before it has a chance to dry and flash rust, spray it down with tri sodium phosphate and water solution. You can get the TSP in powder form in paint dept at lowes or home depot.

moparmat2000

Well-Known Member

Dip control arms, or anything else you want to de rust. Cast iron and sems nuts and bolts it will eat badly though.

Dip control arms, or anything else you want to de rust. Cast iron and sems nuts and bolts it will eat badly though.

The guy I use for my machine work has a huge bead blast chamber. I will just give him the K-Frame and large parts and he will just tank them and blast them for me. I have NO idea where to even by molasses in Southern Arizona

-

Similar threads

- Replies

- 177

- Views

- 5K

- Replies

- 11

- Views

- 605