Think the way to make one is just go full out good to say 10K without breaking up. If I had the time I would give it a shot just to many Irons in the fire now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1974 Brain Box saves the day.

- Thread starter George Jets

- Start date

-

Think the way to make one is just go full out good to say 10K without breaking up. If I had the time I would give it a shot just to many Irons in the fire now.

As a resource on this quest I have a brother that is an electrical engineer who has been designing computer chips for the last 15 years. Bet he could draw up a design layout for our boards.

Knowing what internal parts we would need, could probably build and solder together parts from Radio Shack to get a first rough draft off the ground.

Like the idea of a 10,000 rpm no limit version just to keep it simple.

There are lots of smart people on here that could guide us along to the next steps to make it happen.

I just have a real hard time believing in today's tech world that the manufacturing industries have not been able to come up with a new reliable ignition module off of the mopar original design.

With manufacturing coming back to the USA now, good possibilities to get them done. We might have to show them how to do it though.

I find it interesting how this old stock mopar board has hand written component numbers, probably from the '70s.

Kind of makes you wonder what the manufacturing process was at the time. They did work well though.

Maybe some of this numbering and lettering of the components means something to the better educated electronics people on our site here ?

Kind of makes you wonder what the manufacturing process was at the time. They did work well though.

Maybe some of this numbering and lettering of the components means something to the better educated electronics people on our site here ?

pishta

I know I'm right....

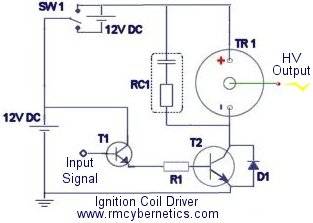

R is resistor, D is diode band side is direction of flow --->|- C are capacitors , triangle 3 pins are transistors (BCE) you could pop the board out and show us the back side traces and we can come up with a schematic. Once you get the schematic out there, you can overbuild it to your taste, (300V TO-3, Massive isolated heat sink, cooling fan, etc) I know there is a handwritten one out there somewhere. IIRC @KitCarlson made an ignition circuit and there are DIY projects out there. I think the dwell circuit is only thing not a few transistors cant do switching wise. This one has no dwell circuits but look how simple the switching is, 5 components! There are even digital projects out

there. Programmable Digital Ignition

there. Programmable Digital Ignition

They (manufacturers) don't know there is a need. The tough thing about doing something like this is the design and set up cost is the same whether you make 50 or 50,000. The end cost of the product is hugely different between the two though.As a resource on this quest I have a brother that is an electrical engineer who has been designing computer chips for the last 15 years. Bet he could draw up a design layout for our boards.

Knowing what internal parts we would need, could probably build and solder together parts from Radio Shack to get a first rough draft off the ground.

Like the idea of a 10,000 rpm no limit version just to keep it simple.

There are lots of smart people on here that could guide us along to the next steps to make it happen.

I just have a real hard time believing in today's tech world that the manufacturing industries have not been able to come up with a new reliable ignition module off of the mopar original design.

With manufacturing coming back to the USA now, good possibilities to get them done. We might have to show them how to do it though.

R is resistor, D is diode band side is direction of flow --->|- C are capacitors , triangle 3 pins are transistors (BCE) you could pop the board out and show us the back side traces and we can come up with a schematic. Once you get the schematic out there, you can overbuild it to your taste, (300V TO-3, Massive isolated heat sink, cooling fan, etc) I know there is a handwritten one out there somewhere. IIRC @KitCarlson made an ignition circuit and there are DIY projects out there. I think the dwell circuit is only thing not a few transistors cant do switching wise. This one has no dwell circuits but look how simple the switching is, 5 components! There are even digital projects out

there. Programmable Digital Ignition

View attachment 1715622498

That is just awesome, will look into this more. Will try to get that board out of that blue 4 pin case without destroying it.

Then can see what is on the other side.

R is resistor, D is diode band side is direction of flow --->|- C are capacitors , triangle 3 pins are transistors (BCE) you could pop the board out and show us the back side traces and we can come up with a schematic. Once you get the schematic out there, you can overbuild it to your taste, (300V TO-3, Massive isolated heat sink, cooling fan, etc) I know there is a handwritten one out there somewhere. IIRC @KitCarlson made an ignition circuit and there are DIY projects out there. I think the dwell circuit is only thing not a few transistors cant do switching wise. This one has no dwell circuits but look how simple the switching is, 5 components! There are even digital projects out

there. Programmable Digital Ignition

View attachment 1715622498

Like the overbuilding idea, massive heat sinks, and cooling fan ideas. Been doing som thinking here . . keep it all going.

This is getting fun!

Think the big thing is going to be getting new plug sockets.

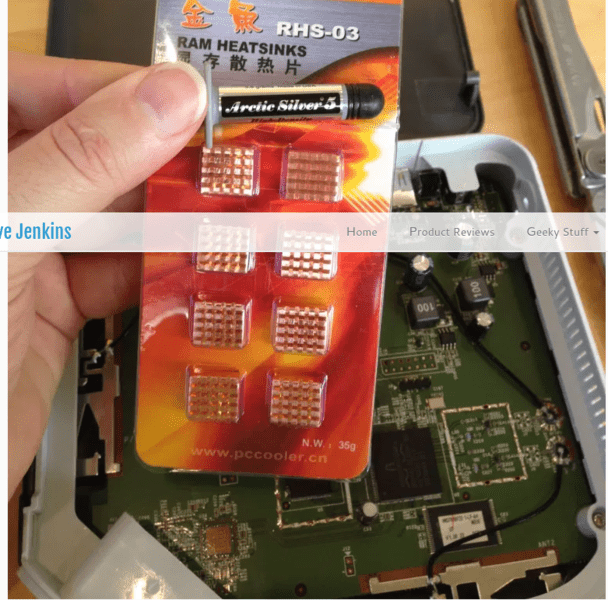

Some Heat Sinks that could be added (thermal pasted on) to the original Gold Heat Sinks for better Transistor Cooling.

Rev-N-Nators pictured here 2016 models

Rev-N-Nators pictured here 2016 models

The heat has to get out of the case. Vents or a expansion valve?

Just wanted to write up this little thing about pulling the heat out of these control modules, reducing failures and increasing electricity flow rates.

1. Heat travels to lesser heat

2. You cannot create Cold, but you can remove the Heat. (as in the air conditioning world)

3. Heating a metal conductor makes it more difficult for electricity to flow through it. These collisions cause resistance and generate heat. ... Heating the metal conductor causes atoms to vibrate more, which in turn makes it more difficult for the electrons to flow, increasing resistance.

4. So keeping the control modules cool, decreases electrical resistance.

5. Overheated electrical components causes them to melt down and fail.

6. Electricity follows the path of "Least Resistance"

1. Heat travels to lesser heat

2. You cannot create Cold, but you can remove the Heat. (as in the air conditioning world)

3. Heating a metal conductor makes it more difficult for electricity to flow through it. These collisions cause resistance and generate heat. ... Heating the metal conductor causes atoms to vibrate more, which in turn makes it more difficult for the electrons to flow, increasing resistance.

4. So keeping the control modules cool, decreases electrical resistance.

5. Overheated electrical components causes them to melt down and fail.

6. Electricity follows the path of "Least Resistance"

The heat has to get out of the case. Vents or a expansion valve?

Guess we are thinking on the same lines here Halifax, was writing up a reply as you were posting your's.

Keep it goin' . . .

Talking about heat sinks, what is the operating temp of the transistor and the unit as a whole? Would there be a benefit to installing it in the cabin and getting it out from under the hood and away from 600° exhaust?

Talking about heat sinks, what is the operating temp of the transistor and the unit as a whole? Would there be a benefit to installing it in the cabin and getting it out from under the hood and away from 600° exhaust?

Good Point !

Would like to take a lazer heat temp gun and find out what the running temp is there at the gold heat sink right at the Top Hat Chrome Transistor casing of the module.

The bigger engines with headers are definatly increasing engine bay temperatures, maybe so much so that they are stressing the control modules and leading them to failures.

I'm surprised that the aluminum u shaped channel even dissipates enough heat This is a heat sink. But it will just absorb heat if the underhood temps are higher than the transistor puts out.

I'm surprised that the aluminum u shaped channel even dissipates enough heat This is a heat sink. But it will just absorb heat if the underhood temps are higher than the transistor puts out.

View attachment 1715622570

Yes that's a good point too.

If hot heat from headers in engine bay or even just a high perf engine dumping more heat those external heat sinks could bring heat into the modules and make them over heat.

This could be happening right now with even the mopar stock boxes. They could be in a hotter environment than they were designed to run in.

One thing that could be making them fail, or even start missing at high rpms cause they are getting hot ???

Edit: With the heat sinks got to be able to carry the heat away from them, preferably to the outside of the car body.

Just did a little test run up on my '76 D100 Truck, checking the heat at the factory heat sinks. Tried multiple different modules all the same.

They run like 10° above outside temperature here idling a few minutes. Temp may go a little higher running them down the road.

I was surprised at the temp at the top terminals of the 4 post ballast resistor, got pretty warm like 180°, tried another ballast resistor and was the same.

Bottom terminals were cool. Guess they are supposed to run like that, just have never taken a heat test gun to them before.

They run like 10° above outside temperature here idling a few minutes. Temp may go a little higher running them down the road.

I was surprised at the temp at the top terminals of the 4 post ballast resistor, got pretty warm like 180°, tried another ballast resistor and was the same.

Bottom terminals were cool. Guess they are supposed to run like that, just have never taken a heat test gun to them before.

pishta

I know I'm right....

They are thermal ballast resistors, designed to heat and change value with the heat. As you stated the hot resistors resists more, reducing the voltage to the ignition system to prolong life of it. Then you have the bypass for start condition. That's why the ballast resistor is stood off from the firewall. Got A/C? Run the ignition box on top of the freezing A/C feed. My pipe ices up after the expansion valve in the engine compartment whennits working. The blower resistors for the fan speed control ar in the plenum of semi modern cars to keep them cool. As they are dumping big watts through those resistors to slow a dc motor and that creates lots of heat.

@pishta and others,

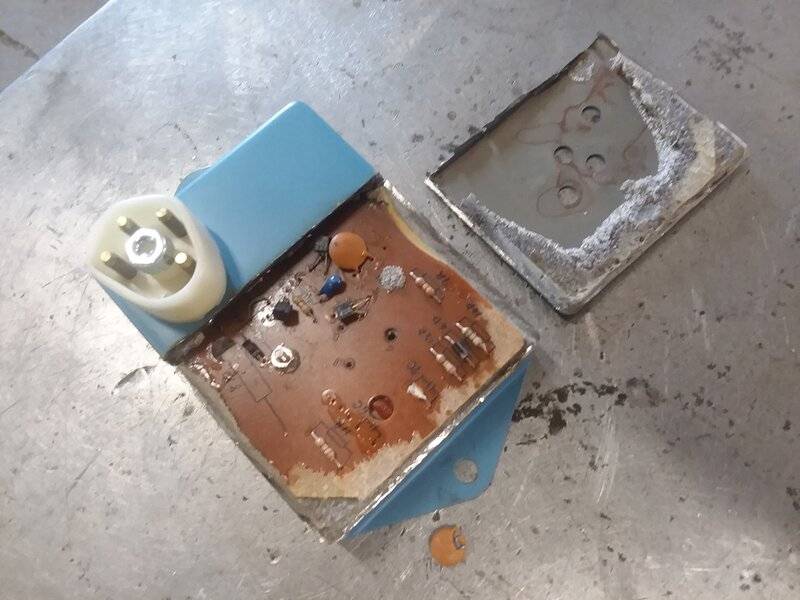

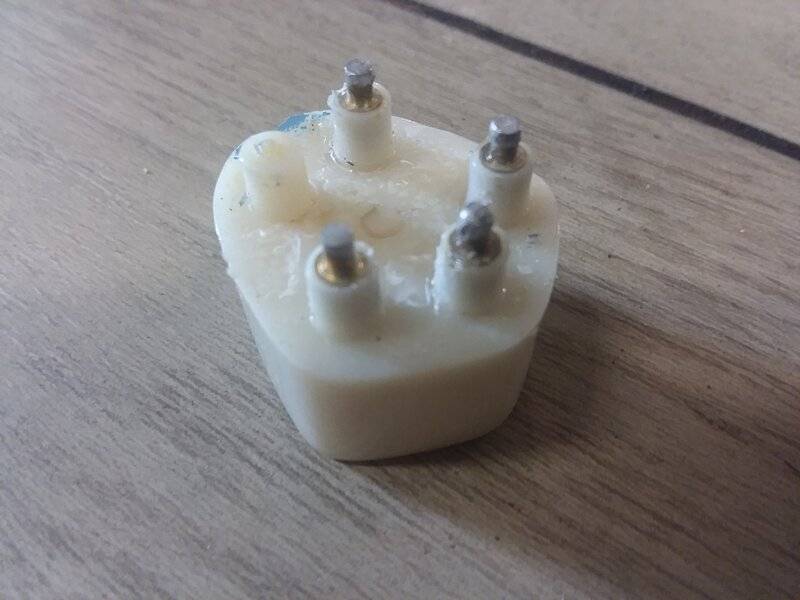

Here is the board out of the old stock 4 pin Blue Brain Box.

For the most part it looks relatively simple, though I don't understand it. If I had diagrams and parts I could probably put one together.

Anyhow will see if anyone else can make sense of all off this. It was a working unit before teardown. Trying to find possible failure points as I am going through these, have not found any so far.

Other than keeping the internals cool and heat sinks pulling the heat out, that is about all I can see for now in areas of improvement.

Looks like the plugs can be harvested from used non-working units for now for reuse.

Mostly just the epoxy remaining in the bottom of the case yet. Glad that it let go of fhe board so I could get it out.

Here is the board out of the old stock 4 pin Blue Brain Box.

For the most part it looks relatively simple, though I don't understand it. If I had diagrams and parts I could probably put one together.

Anyhow will see if anyone else can make sense of all off this. It was a working unit before teardown. Trying to find possible failure points as I am going through these, have not found any so far.

Other than keeping the internals cool and heat sinks pulling the heat out, that is about all I can see for now in areas of improvement.

Looks like the plugs can be harvested from used non-working units for now for reuse.

Mostly just the epoxy remaining in the bottom of the case yet. Glad that it let go of fhe board so I could get it out.

A few transistors and ceramic capacitors and a bunch of resistors.

After a second look at what is left of the case and the epoxy, looks like there may be a whole other secondary board down in all that epoxy. Don't know how I would get that out without total distruction..

I do have a photo of the back of my '74 module that melted most of that out from the hot Florida Sun as a clue to what is in there.

This one from '74 looks really nasty, though it performs perfectly yet. That's the way i like to see them built. Coming in half shot up and still working like a charm.

Blue 4 pin below:

'74 heat ravaged module below:

Mopar Original '74

I do have a photo of the back of my '74 module that melted most of that out from the hot Florida Sun as a clue to what is in there.

This one from '74 looks really nasty, though it performs perfectly yet. That's the way i like to see them built. Coming in half shot up and still working like a charm.

Blue 4 pin below:

'74 heat ravaged module below:

Mopar Original '74

I have to ask this what is every ones electronics backgrounds? I was a Avionics shop Chief in the USAF for 18 years. Back when I started we actually repaired the internal board in the boxes. Bet we have some serious knowledge here on this thread

Retired (well sort of) Electrical Engineer. Spent most of my life in defense electronics.

Lots of good work on this. Has anyone examined a failed box to see what part actually failed? It appears that we are focused on the power transistor as the failure cause. I agree that it is a likely culprit, but do we have any evidence? My average blindfolded with a shotgun isn’t all that good....

Lots of good work on this. Has anyone examined a failed box to see what part actually failed? It appears that we are focused on the power transistor as the failure cause. I agree that it is a likely culprit, but do we have any evidence? My average blindfolded with a shotgun isn’t all that good....

This Standard Product LX100 with the TO220 internal transistor failed (china made) replaced with same and is working fine now.

Failed after 1 year, the picture of the TO220 transistor here looks fine, no black smoke or heat damage.

-

Similar threads

- Replies

- 3

- Views

- 416

- Replies

- 4

- Views

- 457