Unmilled J heads will take .040 to get to minimum. So, IF unmilled heads, then that puts the chambers around 73cc. Since you have 10.5 340 pistons, that will get you close enough for picking the right cam. I just ordered a solid cam for my low compression 340 from Racer Brown. Call a couple cam manufacturers and get their input.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

camshaft for mild 340

- Thread starter j.d.duggan

- Start date

-

abodyjoe

Well-Known Member

I’m running a summit can that’s a step or two above a stock 340 cam. You would probably really like it. I have the number at home but won’t be home till tomorrow night.

abodyjoe

Well-Known Member

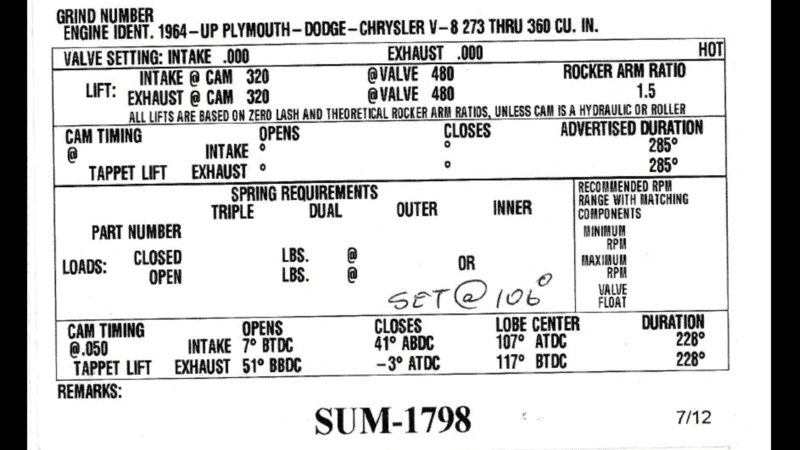

Ok was able to grab it from my phone.

Wyrmrider

Well-Known Member

rumb

I never said assume low compression

I said if he did have a later 340 then you go one way

with his build he has a lot more choices

The 268 comp is short for the amount of lift- go voodoo instad, or howard, or Bullet, or custom Engle, Crower etc

the summit can be had cheaper as an Elgin yet another chevy regrind

the DC cam is fine but obsolete and pricey

I never said assume low compression

I said if he did have a later 340 then you go one way

with his build he has a lot more choices

The 268 comp is short for the amount of lift- go voodoo instad, or howard, or Bullet, or custom Engle, Crower etc

the summit can be had cheaper as an Elgin yet another chevy regrind

the DC cam is fine but obsolete and pricey

That summit cam is REALLY close to the old 280/480 mopar camshaft. It's cut on a little wider LSA 112 vs 110 IIRC

Another inexpensive camshaft that works well is the old 214/224 cam. Faster lift stuff is nice but also has greater potential for failure and other parts not playing nice.

Pick your parts, pay your money!

Another inexpensive camshaft that works well is the old 214/224 cam. Faster lift stuff is nice but also has greater potential for failure and other parts not playing nice.

Pick your parts, pay your money!

Same reason why I recommended the intermediate priced grind I did. Not a super fast rate, but not slow either, card spec matches the rest of the OP's combo nicely, a little more "lope' at idle but still have excellent street manners. Sure there is more power on the table, but this choice should still play with all the other components nicely and have very good street manners.

Read below.rumb

I never said assume low compression

No you didn’t.I said if he did have a later 340 then you go one way

Pricey yes, obsolete? What is obsolete about what works?the DC cam is fine but obsolete and pricey

Wyrmrider ....

stock 340 cam in low compression motor leaves a lot on the table without converter and gears

Oh never mind!

QuickDart360

Well-Known Member

Hey vntned! So off topic but really want to know what wheels are on the dart? Also if you don't mind dimensions like backspace frobt and back.Comp Cams 268AH-10

It's basically a stock 340 cam with a more modern split grind. I love it in my 360. It's 9.4:1cr with 1.88/1.60 Jheads.

moper

Well-Known Member

My vote is a Comp XE268

me too.

vntned

Well-Known Member

Your gonna have to remind me of which wheels you need the specs on.

QuickDart360

Well-Known Member

Oh sorry not aware of the others. The last set of wheels which look gold or bronze color. Just very subtle but cool looking!Your gonna have to remind me of which wheels you need the specs on.

View attachment 1715287574

View attachment 1715287575

View attachment 1715287576

vntned

Well-Known Member

Those were Cragar Eliminator 500 wheels. 17x7s up front and 17x8s in the back. Off set has slipped my mind currently. You might be able to search my old posts and find the info.

Wyrmrider

Well-Known Member

garret et al

check the .200 duration of the Summit, 268 and 270 comp, 214/224 etc and compare with the DC you end up with a lot of duration for the area under the curve= power

The 284 DC checking at .008 is a lot bigger than the 284 Summit checked at .004 compare apples and oranges

COmp 268 (checking at .006) is way too expensive for what you get as is the DC

the mild .904 cam grinders I mentioned are actually less radical than the 268 comp which at its time was pushing the envelope for a chevy grind

yes rumble obsolete

designed back when jerk was not considered by the big grinders except by Crane the newer designed with a modern computer instead of a hand calculator or first generation computer that Harold Berkshire used are a lot smoother and easier on the valvetrain

check the .200 duration of the Summit, 268 and 270 comp, 214/224 etc and compare with the DC you end up with a lot of duration for the area under the curve= power

The 284 DC checking at .008 is a lot bigger than the 284 Summit checked at .004 compare apples and oranges

COmp 268 (checking at .006) is way too expensive for what you get as is the DC

the mild .904 cam grinders I mentioned are actually less radical than the 268 comp which at its time was pushing the envelope for a chevy grind

yes rumble obsolete

designed back when jerk was not considered by the big grinders except by Crane the newer designed with a modern computer instead of a hand calculator or first generation computer that Harold Berkshire used are a lot smoother and easier on the valvetrain

That summit cam is REALLY close to the old 280/480 mopar camshaft. It's cut on a little wider LSA 112 vs 110 IIRC

Another inexpensive camshaft that works well is the old 214/224 cam. Faster lift stuff is nice but also has greater potential for failure and other parts not playing nice.

Pick your parts, pay your money!

Exactly! Slow, reliable ramps have their place!

I got news for all yall. You can say this and that is obsolete all you want. Pick a recipe out of the MP engine book. Any of them. Use the cam they have chosen with all the other parts in the recipe. The engine will run the number. Obsolete? I think not.

Wyrmrider

Well-Known Member

a slow reliable .904 grind will wipe a slow reliable .842 grind

IT takes a fast .842 grind to stay with a moderate .904 grind like the MPs

50 year old designs gimme a break

Sure use all the parts in the MP books, now where do you get the gas

IT takes a fast .842 grind to stay with a moderate .904 grind like the MPs

50 year old designs gimme a break

Sure use all the parts in the MP books, now where do you get the gas

a slow reliable .904 grind will wipe a slow reliable .842 grind

IT takes a fast .842 grind to stay with a moderate .904 grind like the MPs

50 year old designs gimme a break

Sure use all the parts in the MP books, now where do you get the gas

Never said they were the best of the best. I said they still work and they do.

...and none of the MP grinds are 50 year old designs. They were all reworked in the 1980s to take more advantage of the .903 lifter diameter. Yes, it's been a while, but that is a fact.

I know that there is more than one car that runs 11's with that dinky 214/224 cam, stock rockers, in 360's with well ported J style heads and a great chassis.

.904 or not, you can make good power and be easy on parts with any number of combinations. Not everything has to be used to the optimal level.

Key word in the OP... MILD!!!!

Make what you got work. There are good grinds out there, choose one and go with it.

.904 or not, you can make good power and be easy on parts with any number of combinations. Not everything has to be used to the optimal level.

Key word in the OP... MILD!!!!

Make what you got work. There are good grinds out there, choose one and go with it.

Your asking people to compare and search for these things that they never thought of before in an effort to support your position in splitting hairs to prove that you are right. I agree but also stand by what I always say.a slow reliable .904 grind will wipe a slow reliable .842 grind

IT takes a fast .842 grind to stay with a moderate .904 grind like the MPs

50 year old designs gimme a break

Sure use all the parts in the MP books, now where do you get the gas

I just find it crazy and pathetic that every build you comment require a designated 904 cam. The power difference is insanely small for f even available in low power builds. You know what I mean.

Obsolete as in it doesn’t work anymore.yes rumble, obsolete

Give me a break!

Come on man, stop splitting hairs.

Mike Beck did just that with a, as wyrm would say, a slow lazy ramp Crane cam of very similar specs, over 10 years ago.I know that there is more than one car that runs 11's with that dinky 214/224 cam, stock rockers, in 360's with well ported J style heads and a great chassis.

Wyrmrider

Well-Known Member

the 214-224 is 50 years old and the Cam Dynamics> Crane Summit- if that is what they use is almost that old

Obsolete as in you can do much better today

power difference may be small but torque is much better

I've used lots of the 204-214 and 214-224 back in the day but not now

yep key word is MILD

I can run 10 degrees shorter with a MOPAR cam with the same pull

Obsolete as in you can do much better today

power difference may be small but torque is much better

I've used lots of the 204-214 and 214-224 back in the day but not now

yep key word is MILD

I can run 10 degrees shorter with a MOPAR cam with the same pull

txstang84

Well-Known Member

Scroll to the bottom of the above linked page.

What I like about this is the in general build perameters, except the missing duration @ .050, and it's reasonable power output while maintaining good drive abilty with the wider centerline cams.

Thisis good everyday streeter tips.

What I like about this is the in general build perameters, except the missing duration @ .050, and it's reasonable power output while maintaining good drive abilty with the wider centerline cams.

Thisis good everyday streeter tips.

Computer simulations show what happens when we increase compression, add duration in different combinations and then adjust lobe centers using a hypothetical Chevrolet 350 engine assembled with different combinations of compression, camshafts and valve timing as a base.

Stage 1 Base Engine Analysis

Typical low performance: Standard 1.94 and 1.50 valves with typical port flow, OE dual plane 4bbl intake, OE exhaust manifolds and single exhaust.

Static Compression Intake Duration Exhaust Duration Lobe Centers

Fuel

Stage 2

8.25:1

250 Degrees 260 Degrees 110 Degrees 87 Octane

Volumetric Efficiency Torque/RPM

HP/RPM

Effective Compression Vacuum

Analysis

86.7% 360/3,000 245/4000 7.13:1 20.9 in/Hg

Mild production performance: Standard 1.94 and 1.50 valves with typical port flow, OE dual plane 4bbl intake, OE exhaust manifolds and dual exhaust.

Static Compression Intake Duration Exhaust Duration Lobe Centers

Fuel

Stage 3

9.25:1

260 Degrees 270 Degrees 112 Degrees 87 Octane

Volumetric Efficiency Torque/RPM

HP/RPM

Effective Compression Vacuum

Analysis

87.2% 373/3,000 268/4,500 7.61:1 21.1 in/Hg

Performance engine: Larger 2.02 and 1.60 valves and mild porting, single plane aftermarket intake and 1-5/8 x 36 in. headers with low restriction mufflers. With the increased effective compression and volumetric efficiency, premium fuel is recommended.

Static Compression Intake Duration Exhaust Duration Lobe Centers

Fuel

10.0:1

288 Degrees 288 Degrees 114 Degrees 91 Octane

Volumetric Efficiency Torque/RPM

HP/RPM

Effective Compression Vacuum

94.8% 404/4,500 372/5,500 7.55:1 19.6 in/Hg

NOTE — In all but the last stage, “dual pattern” camshafts with increased exhaust duration were required to achieve 75 percent or better exhaust flow relative to intake. Also, note vacuum was kept within a range of 1.4 in/Hg for all three engines. (Ithink there talking about wide open throttle vacuum readings here.)

Last edited:

PRH

Well-Known Member

My experience has been that the “computer simulations” and “hypothetical” engines, built in the software world........ benefit from wide lsa’s a lot more than(typical street, street/strip, basic racing type) real engines tested on real dynos.

Unless you’re not using headers.

Of course.......YMMV.

Unless you’re not using headers.

Of course.......YMMV.

txstang84

Well-Known Member

No argument there; I think it's more meant to give those who have legitimately no knowledge about the particular subject a basis for understanding how cam timing events can affect an engines behavior...

-

Similar threads

- Replies

- 105

- Views

- 6K

- Replies

- 43

- Views

- 2K

- Replies

- 33

- Views

- 1K

- Replies

- 38

- Views

- 3K

- Replies

- 14

- Views

- 1K