I have read about every post on this forum as well as the B-body, C-body, Moparts, MAD Electrical, etc forums on this topic. Most of these discussions are centered on eliminating/bypassing the ammeter as they can be prone to be a location or source of fires, thermal issues, etc. The MAD Electrical ammeter bypass threads often get into how to improve upon the charging circuit since our beloved old Mopars can definitely use some help there.

I'm working on my 71 Demon 340 and although 50 years old, this car only has 40k miles on it (I've owned it since 1984) so the hardware has more time than miles on it. BUT...the wiring is still 50 years old and pretty crispy so I'm replacing all of the harnesses in it (engine, wiper, trans, front end lighting) but I am not replacing the underdash harness. This gets me all new junction block connectors on the engine side of the firewall. When I pulled the IP out, the dash harness looks to be in pretty good shape but the junction block connectors will still be the original on the pass side of the firewall. Just for good measure, I plan to change out the terminals on the higher current circuits so these connections will be fresh on both sides.

BUT...while I'm at it...and after reading all of the threads as I mentioned on the ammeter bypass, I'm thinking there is a way to reduce the load on the ammeter while still keeping it functional. (It won't read anything meaningful but it will stay somewhat centered in the gauge reading.) So my thinking....

The original wiring running a loop from the alternator output through the firewall then through the ammeter and back through the firewall to the B+ side of the battery to charge it does have some downsides. (The power to feed the car comes on the alternator side of this wiring circuit.) And since these are only 12ga wires...well, with age and temperature, that can be a lot to ask of the wires and the smallish terminals in the bulkhead connectors. But if you want to read current and whether it is flowing from the battery to feed the car or if it is flowing from the alternator to feed the car and charge the battery, that is how it was done for the type of gauge MaMopar used. The killer for this wire circuit is when the battery is low and being fed a lot of amps from the alternator. When this occurs, the 12 ga wire from the alternator and through the bulkhead connector has to carry the full alternator current output to feed the car and the current to charge the battery at the same time.

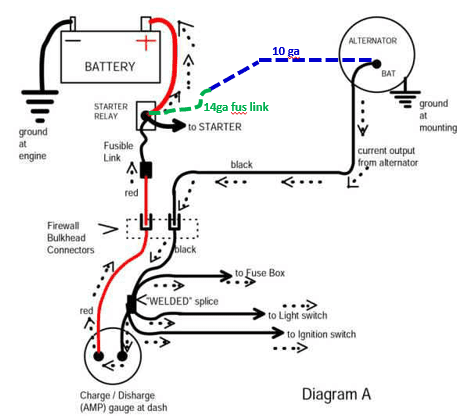

To improve upon this, I propose just following part of the MAD proposal and some others and simply provide a direct charging path from the alternator to the battery. This would be done by adding a wire straight from the alternator output to the B+ at the starter relay. Then simply leave the rest of the wiring intact. It would look like this - with the blue 10ga wire and green 14ga fusible link as the added wiring. (Note that I have reused the base schematic that someone else on another site created but is also used on the MAD Electric site.) (In reality, I would use black for the new wire circuit but are shown in blue and green for clarity.) Adding this new wire is pretty straightforward to do as it would route in the same harness with the current alternator wires and then back by the bulkhead connector, simply jump into the starter relay part of the engine harness.

This essentially provides a direct, unencumbered path to charge the battery. The charging load would all be carried by the new wire while the original black 12ga wire running into the car from the alternator would now only carry the current required to run the car. Gone would be most all of the current to charge the battery so that wire load goes WAY down.

At idle, when these old alternators don't put out much current, the battery will still feed the car through the original wiring as before and discharge some as they always do. But with the new wire added, once rpm rises and the alternator starts to generate current, the battery recharging will go mostly through the new wire instead of through the inside of the car like it does with the original design. (Yes, there may still be some charging current flowing on the orig path but it will be GREATLY reduced.) The ammeter will still "function" - meaning it will still show any current flowing through it but other than the discharging at idle (or an alternator malfunction), there won't be much current flowing through it.

Alright - let's hear it from some of those FABO electrical gurus. While I have experience with electrical systems in these cars, I'd like to hear from some of you experts in case I may be missing something - because bad wiring can lead to trouble in a hurry!!

Here's comin at ya....!!

I'm working on my 71 Demon 340 and although 50 years old, this car only has 40k miles on it (I've owned it since 1984) so the hardware has more time than miles on it. BUT...the wiring is still 50 years old and pretty crispy so I'm replacing all of the harnesses in it (engine, wiper, trans, front end lighting) but I am not replacing the underdash harness. This gets me all new junction block connectors on the engine side of the firewall. When I pulled the IP out, the dash harness looks to be in pretty good shape but the junction block connectors will still be the original on the pass side of the firewall. Just for good measure, I plan to change out the terminals on the higher current circuits so these connections will be fresh on both sides.

BUT...while I'm at it...and after reading all of the threads as I mentioned on the ammeter bypass, I'm thinking there is a way to reduce the load on the ammeter while still keeping it functional. (It won't read anything meaningful but it will stay somewhat centered in the gauge reading.) So my thinking....

The original wiring running a loop from the alternator output through the firewall then through the ammeter and back through the firewall to the B+ side of the battery to charge it does have some downsides. (The power to feed the car comes on the alternator side of this wiring circuit.) And since these are only 12ga wires...well, with age and temperature, that can be a lot to ask of the wires and the smallish terminals in the bulkhead connectors. But if you want to read current and whether it is flowing from the battery to feed the car or if it is flowing from the alternator to feed the car and charge the battery, that is how it was done for the type of gauge MaMopar used. The killer for this wire circuit is when the battery is low and being fed a lot of amps from the alternator. When this occurs, the 12 ga wire from the alternator and through the bulkhead connector has to carry the full alternator current output to feed the car and the current to charge the battery at the same time.

To improve upon this, I propose just following part of the MAD proposal and some others and simply provide a direct charging path from the alternator to the battery. This would be done by adding a wire straight from the alternator output to the B+ at the starter relay. Then simply leave the rest of the wiring intact. It would look like this - with the blue 10ga wire and green 14ga fusible link as the added wiring. (Note that I have reused the base schematic that someone else on another site created but is also used on the MAD Electric site.) (In reality, I would use black for the new wire circuit but are shown in blue and green for clarity.) Adding this new wire is pretty straightforward to do as it would route in the same harness with the current alternator wires and then back by the bulkhead connector, simply jump into the starter relay part of the engine harness.

This essentially provides a direct, unencumbered path to charge the battery. The charging load would all be carried by the new wire while the original black 12ga wire running into the car from the alternator would now only carry the current required to run the car. Gone would be most all of the current to charge the battery so that wire load goes WAY down.

At idle, when these old alternators don't put out much current, the battery will still feed the car through the original wiring as before and discharge some as they always do. But with the new wire added, once rpm rises and the alternator starts to generate current, the battery recharging will go mostly through the new wire instead of through the inside of the car like it does with the original design. (Yes, there may still be some charging current flowing on the orig path but it will be GREATLY reduced.) The ammeter will still "function" - meaning it will still show any current flowing through it but other than the discharging at idle (or an alternator malfunction), there won't be much current flowing through it.

Alright - let's hear it from some of those FABO electrical gurus. While I have experience with electrical systems in these cars, I'd like to hear from some of you experts in case I may be missing something - because bad wiring can lead to trouble in a hurry!!

Here's comin at ya....!!