Mattax

Just the facts, ma'am

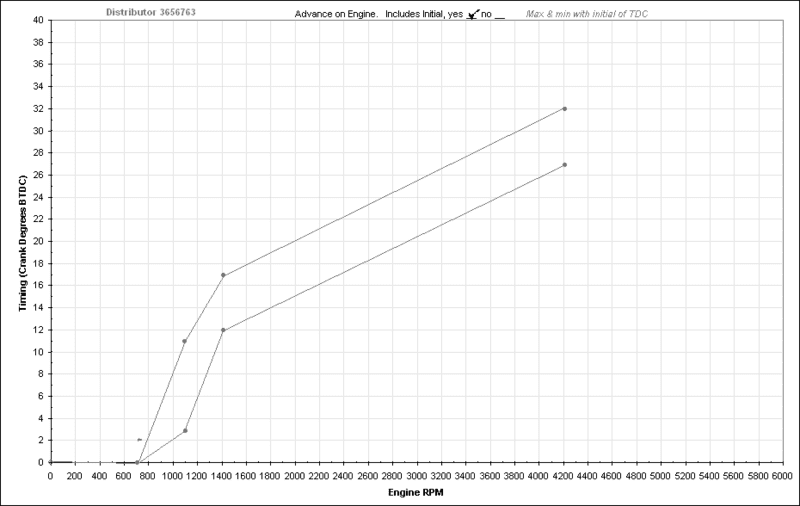

First plot the factory timing ofthat distributor.

I don't know the idle rpm for '74 but the same distributor was used in '73 on 318s and in the fuel section of the FSM it gives idle rpm of 750.

From the book 550 distributor rpm becomes 1100 engine rpm etc.

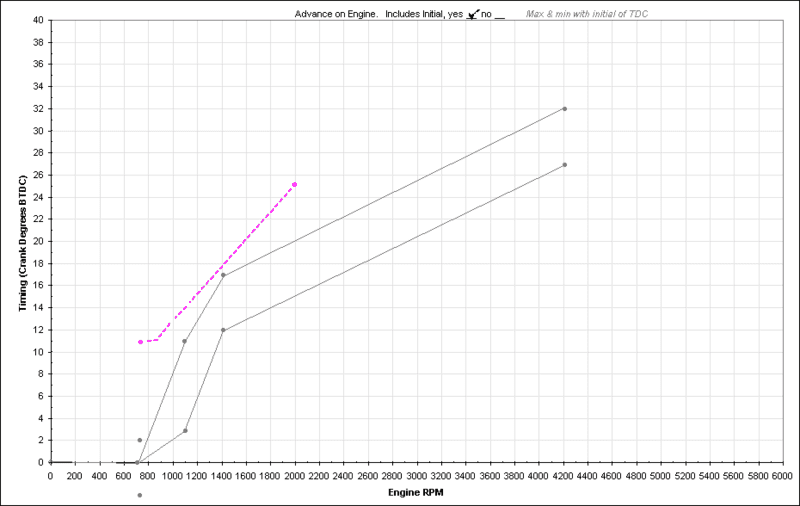

The curve between your two timing measurements (750 and 2000 rpm) will look roughly like this.

The timing will continue to advance at that rate until the wieghts hit the end of the slots.

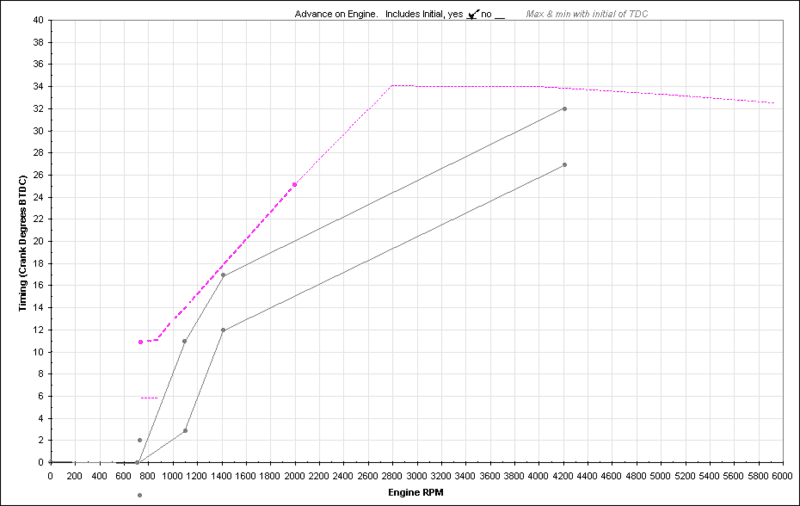

So the rest of the timing probably looks something like this. Make sense?

Go ahead and get some real timing measurements between 750 and 2000 rpm.

I don't know the idle rpm for '74 but the same distributor was used in '73 on 318s and in the fuel section of the FSM it gives idle rpm of 750.

From the book 550 distributor rpm becomes 1100 engine rpm etc.

A second primary spring will roughly double the spring force from idle rpm on up. (The factory heavy spring has a long loop. That spring slows the advance only after the weights have moved outward. The one in your distributor did nothing until the advance had increased 12 to 17*)I think I replaced it with a 2nd factory light spring

The curve between your two timing measurements (750 and 2000 rpm) will look roughly like this.

The timing will continue to advance at that rate until the wieghts hit the end of the slots.

So the rest of the timing probably looks something like this. Make sense?

Go ahead and get some real timing measurements between 750 and 2000 rpm.