rmchrgr

Skate And Destroy

So I made some more progress. Besides the front end, I got the Shumacher torque strap in. The previous owner installed a similar thing but it was pretty crude - just a flat steel bar that bolted between the left side cylinder head and the top of the front frame rail. I guess it worked but for me, there's always a better mousetrap.

For years I had one of these sitting on my shelf from a B body but of course it wouldn't fit a A body, so I got the correct one through Mancini and put it in. Basically it requires drilling two holes in the K frame flanges and bolting in a plate/rod/heim joint thing which bolts to the left motor mount. It was a little tricky to position the plate/bracket thing so it sat relatively flat on top of the flange. Drilling the rear most hole was done from the bottom because there wasn't enough room to get the drill at the proper angle from the top. I ended up drilling blindly but I did OK. Took a little finagling to line it up but I got it in.

Here's the torque strap.

Besides the torque strap thing, I couldn't resist and I got the car back on the ground. After I got the front end rebuilt and in, I got the brakes assembled (except the master cylinder), put the wheels on loosely and set the car down. Its been about a year since I first took it apart so I'm feeling pretty good to be at this point. I am adjusting ride height and some basic alignment things right now. I will have to take some things back apart to finalize everything but it all looks good and rolls pretty easily. I'm stoked!

Here's a pic of the car off jack stands and rolling for the first time in almost a year!

From the back.

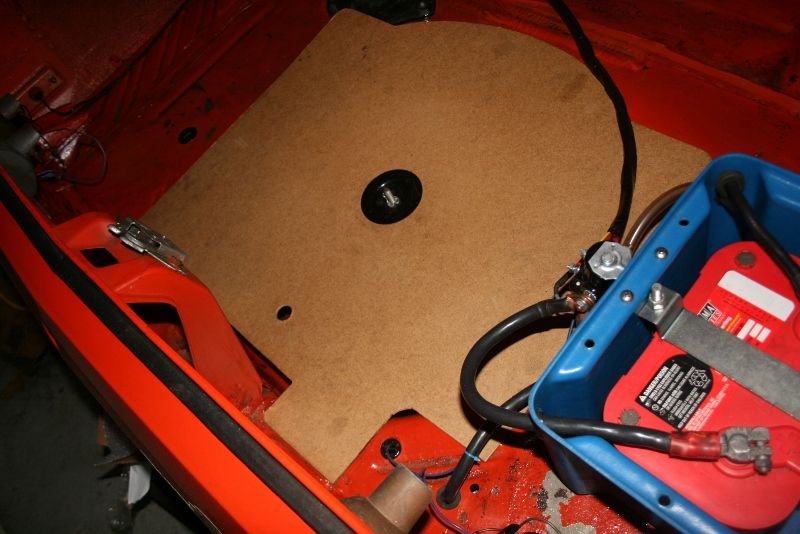

And here's the hole and the mess that was left after I rolled it out. I cleaned up a little after it was out but I have a long way to go. Still, it's a great feeling to see measurable progress.

More to come!

For years I had one of these sitting on my shelf from a B body but of course it wouldn't fit a A body, so I got the correct one through Mancini and put it in. Basically it requires drilling two holes in the K frame flanges and bolting in a plate/rod/heim joint thing which bolts to the left motor mount. It was a little tricky to position the plate/bracket thing so it sat relatively flat on top of the flange. Drilling the rear most hole was done from the bottom because there wasn't enough room to get the drill at the proper angle from the top. I ended up drilling blindly but I did OK. Took a little finagling to line it up but I got it in.

Here's the torque strap.

Besides the torque strap thing, I couldn't resist and I got the car back on the ground. After I got the front end rebuilt and in, I got the brakes assembled (except the master cylinder), put the wheels on loosely and set the car down. Its been about a year since I first took it apart so I'm feeling pretty good to be at this point. I am adjusting ride height and some basic alignment things right now. I will have to take some things back apart to finalize everything but it all looks good and rolls pretty easily. I'm stoked!

Here's a pic of the car off jack stands and rolling for the first time in almost a year!

From the back.

And here's the hole and the mess that was left after I rolled it out. I cleaned up a little after it was out but I have a long way to go. Still, it's a great feeling to see measurable progress.

More to come!