Hey, it‘s me again.

Recently bought a new TCI Streetfighter 904.

It shifts in 3rd only when it is cool.

When kickdown is disconnected it does not shift up in 2nd.

It runs with Dexron 3 (filled right according to dipstick).

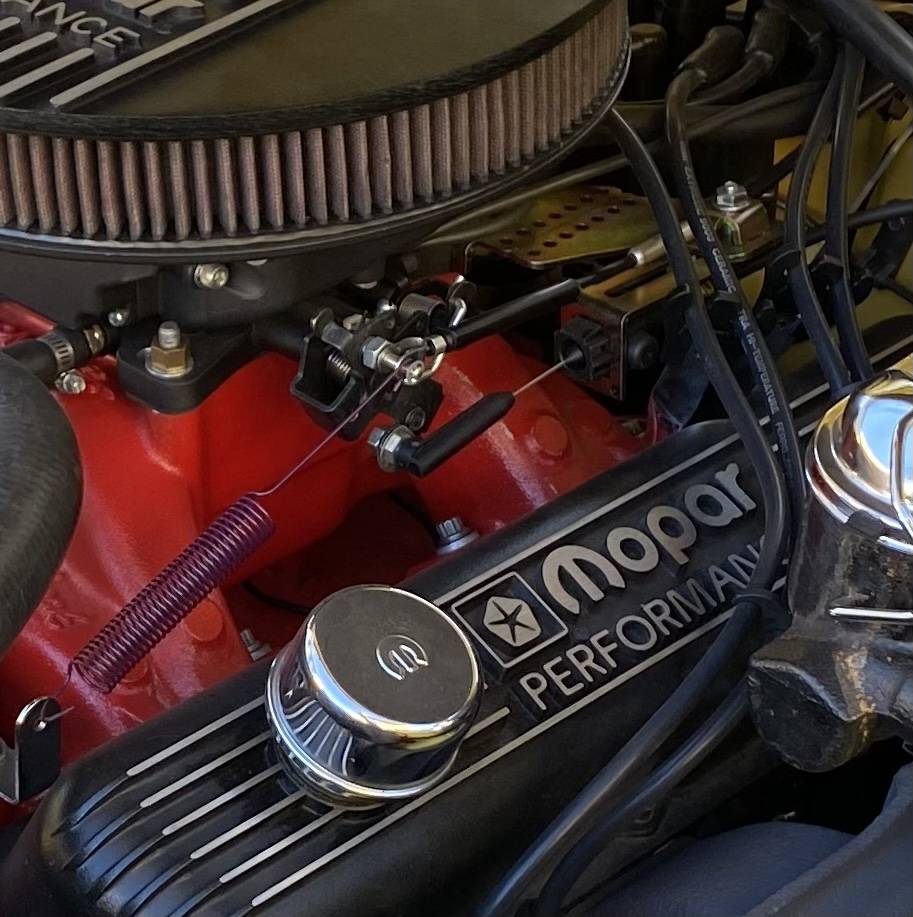

Kickdown cable is from Mancini Racing and it worked good with the original 904.

Holley sniper installed without a bracket for kickdown (worked on old).

I did everything exactly what the manual told me to do…

Don‘t know what to do now :/

Thanks!

Recently bought a new TCI Streetfighter 904.

It shifts in 3rd only when it is cool.

When kickdown is disconnected it does not shift up in 2nd.

It runs with Dexron 3 (filled right according to dipstick).

Kickdown cable is from Mancini Racing and it worked good with the original 904.

Holley sniper installed without a bracket for kickdown (worked on old).

I did everything exactly what the manual told me to do…

Don‘t know what to do now :/

Thanks!

Last edited by a moderator: