The weight has to be perfectly spread out or they break under very little load. Can’t just have 3-4 contact points.Good to know

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stop in for a cup of coffee

- Thread starter toolmanmike

- Start date

-

I have 2, 4 wheel "carts" I have made for other projects. Moves engines around easily on one of them. Just have to modify some...Hahaha well a 318 poly broke one of those

Good to know

I have broke many of those also. In my case, they are strong enough to hold what they claim (or reasonably close) just don't try to move the object as the casters never work as they should. Something will break - you or the cart/dolly/etc. I had a 460/C6 combo on 3 of those 4 caster dollies. They are rated at 1,000lbs each. Broke them all when the casters wouldn't swivel, bent sideways, and broke.

I have 2, 4 wheel "carts" I have made for other projects. Moves engines around easily on one of them. Just have to modify some...

Yep. I added 2x4s to the harbor freight ones and that fixed the problems. The casters work just fine, just the 1/2 in boards aren’t strong enough.I have 2, 4 wheel "carts" I have made for other projects. Moves engines around easily on one of them. Just have to modify some...

I dissembled the wheels and greased the crap out of them. They turn very nice now...Yep. I added 2x4s to the harbor freight ones and that fixed the problems. The casters work just fine, just the 1/2 in boards aren’t strong enough.

Good thing, or you would suffocateGood thing the air is working today

12:00, today’s work is done. Not really, but sorta. Clean up that i have been putting off.

Im just getting ready to start changing these spark plugs in this 2010 5.4 Ford. Had to run errands this morning....

The power supply just arrived (But not for that router) Lol

Good luck. A 11 year old Triton can be disaster. Hope they have been changed before and a little never seize applied.Im just getting ready to start changing these spark plugs in this 2010 5.4 Ford. Had to run errands this morning....

Yup, Actually I talked to Tooljunkie about them. He told me the big issues were in the earlier ones, like 04-07. This Truck has 200K on it. I did call the customer yesterday, and he told me that I am the one that changed them at 100K. If thats the case, then yes I used antisieze. WE will see soon enough....Good luck. A 11 year old Triton can be disaster. Hope they have been changed before and a little never seize applied.

Yes we will..............Yup, Actually I talked to Tooljunkie about them. He told me the big issues were in the earlier ones, like 04-07. This Truck has 200K on it. I did call the customer yesterday, and he told me that I am the one that changed them at 100K. If thats the case, then yes I used antisieze. WE will see soon enough....

Maybe he is a closet GM guy.I just don't understand how a guy could do a full restoration on a car but not know how to shift his Torqueflite out of park without the column in the car.

My thought....Maybe he is a closet GM guy.

Sending you text message on how I did my hemi install from under the cuda.My thought....

Not hard.

Well, it didnt start out well. Just removing the coil bolts 7mm was a challenge. Of course the one in the rear on the pass side (#4) I think. Tucked way up under. Heads on small screws are rusted and diminished in size. Socket slipping. Pulled #3 coil to gain access, And hit the edge of the bolt with a chisel and hammer to break it loose...Now warming engine and will introduce PB Plaster as I break the plugs all loose....Im sure Frank has seen this happen........

Ted and I are taking off to do a barrel pick. First one for us and I hope my Facebook group can get on the label. Here's the sample bottles pulled from 3 different barrels.

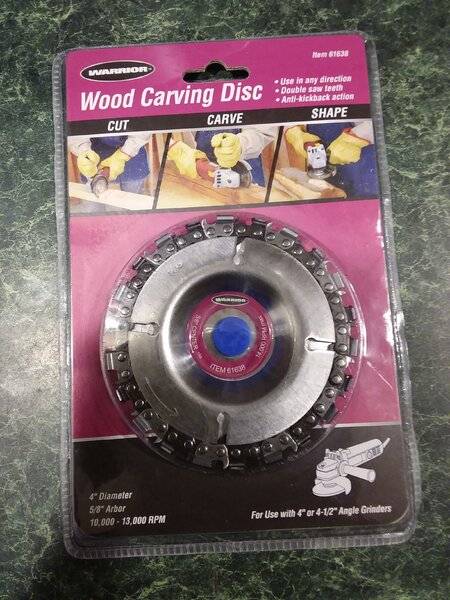

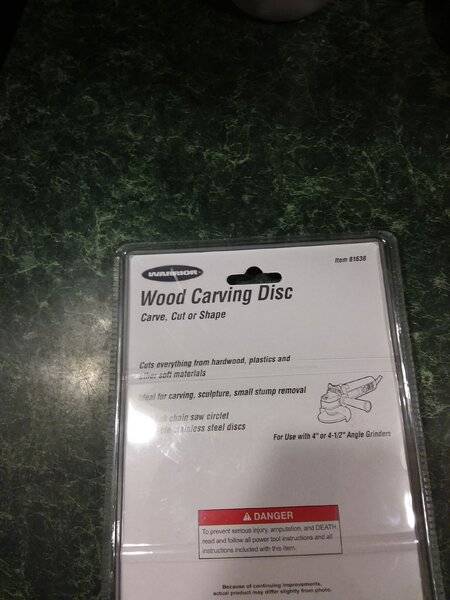

Well I bet you could lose a few fingers on kickback with this on a 4"grinder.

I anti-sieze the screws too. And i barely snug em. Sometimes. I dont like ford pickups. At all.Well, it didnt start out well. Just removing the coil bolts 7mm was a challenge. Of course the one in the rear on the pass side (#4) I think. Tucked way up under. Heads on small screws are rusted and diminished in size. Socket slipping. Pulled #3 coil to gain access, And hit the edge of the bolt with a chisel and hammer to break it loose...Now warming engine and will introduce PB Plaster as I break the plugs all loose....Im sure Frank has seen this happen........

I made a drum with saw chain welded to i for chipping wood. It weighs about 6 lbs and i ran it with a 3 hp electric motor. That thing would eat. Think i used about 6 feet of chain. That was back when i figured making my own wood pellets would be fun. Then i realized it was less work to earn the money and buy the pellets instead of milling my own.Well I bet you could lose a few fingers on kickback with this on a 4"grinder.

View attachment 1715769157

View attachment 1715769158

Unconventional

Well-Known Member

Good news. All the plugs broke loose. Now lettin em soak some before removing completely.....I anti-sieze the screws too. And i barely snug em. Sometimes. I dont like ford pickups. At all.

-

Similar threads

- Replies

- 12

- Views

- 783

- Replies

- 8

- Views

- 745