Well then Jim, until your update, I hope all goes well.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

422 dyno fail

- Thread starter Jim Ward

- Start date

-

Bakerlite

Well-Known Member

- Joined

- Nov 12, 2007

- Messages

- 6,431

- Reaction score

- 3,327

Years ago I was at a shop that had an engine dyno. When I was talking to the guy who ran it, I said it must be good to have that tool on hand. His reply was that after using it for so long he was not very excited to use it anymore. Needles to say I didn't get him to dyno anything for me, because I couldn't be sure he was going to do his best, and not just jump through the hoops for a few bucks.I never dyno tested for a living but it would seem to me that a dyno tester who saw something amiss would suggest some troubleshooting a bit. Changing jetting, using a known good dyno carb, etc. When I went to have a dyno done on my car it was just for assessment on a dynojet. The owner and tester suggested that timing may be too far advanced and he would love to do a dyno tune and not just a test. He was a racer and knew his stuff. I will wait and watch attentively how this pans out and I hope to learn a lot from this. I am speaking not just what was wrong but how to navigate the build, test, retest etc. Good Luck.

Some of the dyno sheets I saw later from this shop just had the very basic info on the data readout sheets.

BVoelzke

Well-Known Member

On my W2 heads the corner exhaust holes are wet... when I went back to my 367 with W2 heads from my Indy headed 408 I forgot the holes were wet resulting in a coolant leak , since the headers I am using don't use the wet holes ( dual bolt pattern on my W2 heads ) I installed set screws with teflon tape and silicone it sealed up fine and solved the leakYears ago I was at a shop that had an engine dyno. When I was talking to the guy who ran it, I said it must be good to have that tool on hand. His reply was that after using it for so long he was not very excited to use it anymore. Needles to say I didn't get him to dyno anything for me, because I couldn't be sure he was going to do his best, and not just jump through the hoops for a few bucks.

Some of the dyno sheets I saw later from this shop just had the very basic info on the data readout sheets.

Zcuda68

Well-Known Member

What kind of valve train are you running. Hp seems really low to me. I had a 408 stroker built and it dynoed at 525 hp and 522 ' lbs of torque. You should be at a minimum of 450 to 550 hp.I get all of that but that low of HP?? I think it should be darn close to 500lb ft. I asked the shop about porting the intake and they didn’t recommend it which also seemed odd to me. I know Edelbrock isn’t known for Optimim HP but again I think it should of at least made 1hp per cube…

Good luck on your build

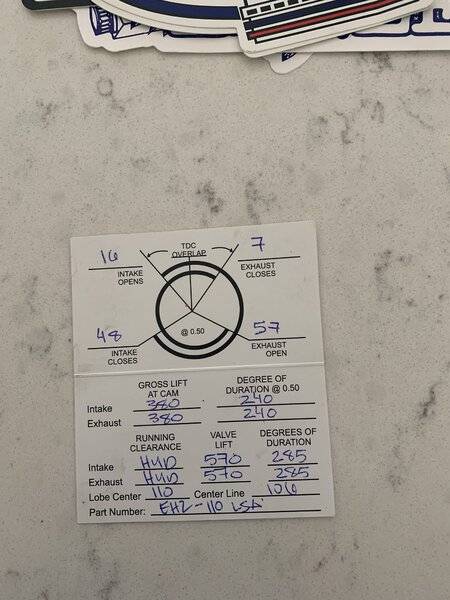

Lunati retrofit roller lifters, hydraulic roller cam, ball/cup push rods crane gold 1.5 rolled rockers.

autoxcuda

Well-Known Member

- Joined

- Apr 6, 2007

- Messages

- 9,519

- Reaction score

- 5,044

E/Stock Duster 340 stock X heads stock cast iron intake stock lift cam stock size pistons stock stroke 10.50 = 543 hp. Yep somethings wrong

Yea, but the duration and other cam events are not stock. Bunch of other stuff going on there. Dedicated race car.

This is more of hot street build.

Jean Genibrel

Member

Go through this site on youtube: youtube nick's garage. Nick only works on Mopar engines and I have seen where he pulled more power with iron heads than with alu ones.Also it would be solid roller for me every time on any of my builds since so far they have all been fairly rowdy to a lot of rowdy......not even gonna consider anything else

One more thing: Did you tell the cam manufacturer the flow you were getting? Does the valve opening go beyond the flow of the head? In other words does the valve continue to open past the max flow of the head?

Jean Genibrel

Member

Check that the vibration damper is not worn out. This happens a lot with old engines and it messes up the ignition and cam timings.I made the mention that the intake was an old design and done around the 340/360 engine. I think it’s a good intake but on the wrong application here. I could be wrong since I’m just only reading things here and not holding parts.

I gave my worthless 2 cents. I’m just going to spectate from here and learn something.

TT5.9mag

Two atmospheres are better than one

I doubt he put an old used damper on a new stroker. And the damper has zero effect on cam timing.Check that the vibration damper is not worn out. This happens a lot with old engines and it messes up the ignition and cam timings.

Not true.Nick only works on Mopar engines

Why are you quoting and addressing me on the above?Check that the vibration damper is not worn out. This happens a lot with old engines and it messes up the ignition and cam timings.

By vibration dampner you mean the harmonic balancer? It is new. I didn’t think this old thing had much life left in it….

Oh! Whoa! Ouch! My eyes, my eyes!!!!!!

Yikes! Damn!

Yikes! Damn!

Jean Genibrel

Member

This is not a question of headers too big or too small. I would start fresh instead of guessing. Check the vibration damper to see if it is damaged and check TDC. Then check the cam timing and start at TDC no advance or retard. Check the compression in all the cylinders. Check that the distributor is working properly. If it still has points install new ones and set the gap to the manufacturer's setting. Check if the base plate is moving correctly and the advance springs are not broken. In fact, have the advance curve checked on a distributor stand (yes, they still make them) Are the spark plugs of the proper heat range? How do they look after a few runs on the dyno(the dyno guy should be able to determine that) are they gapped properly? Adding a spacer to the carburetor may make a difference but you still have a major issue. BTW did you keep the same rod/stroke ratio? And I emphasize ratio not necessarily length. I have a rod stroke ratio calculator you could have. Look at my website APPLIEDSPEED.com Race Engine Rod Stroke Ratio Calculatorhas the dyno guy got some bigger headers he can try? 1 5/8" seems small to me for this size motor. would you put that size header on a big block, even a 383? no, and this is big block cubic inches. air has to get 'out' too, not just in. when you're constipated, you can't eat any more. same thing, lol.

Bakerlite

Well-Known Member

- Joined

- Nov 12, 2007

- Messages

- 6,431

- Reaction score

- 3,327

Looks mint!

Jean Genibrel

Member

Well said. This is why I suggested going through the basics again and checking the vibration damper, cam, and ignition timing, come to think it, check that the cam is appropriate for that engine and application, and check the timing.Several responses to this thread were raising some theoretical red flags as to why the power was so low.

I’ve tested enough stuff with way less than optimum combinations that made decent power and ran down the track pretty well so that those items don’t look as problematic to me.

He ain't got Eddies. Factory heads go into the water jacket at the four outermost holes.My Eddies and new heads do not go through water

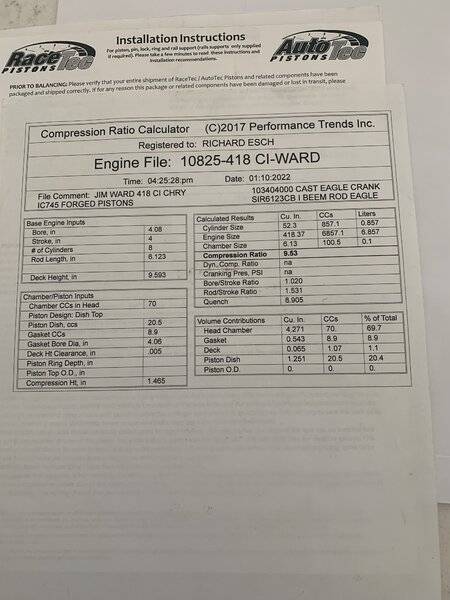

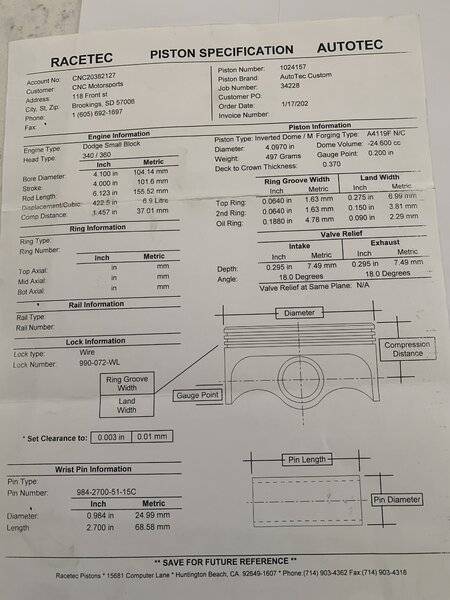

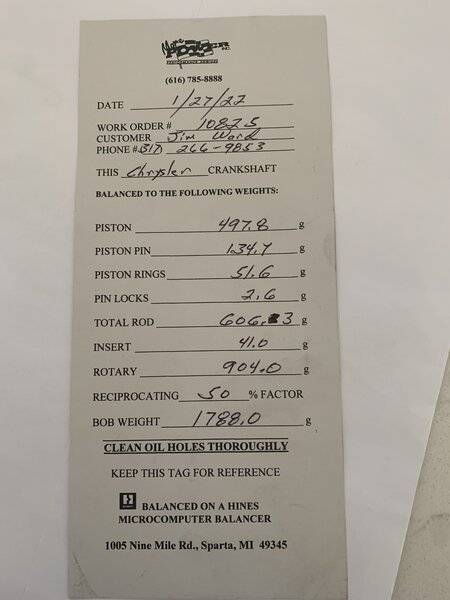

Here is more specifics for your bathroom enjoyment on the build.

Removed because of personal phone number on paper work

Removed because of personal phone number on paper work

Last edited by a moderator:

Jean Genibrel

Member

I thought after you had your motor off the dyno you discovered something that was the likely cause of the lower than expected power?

The top end of the run on the last sheet from the OP had the bsfc numbers in the .7 range.

In 32 years, I don’t think I’ve ever seen them that bad....... not without a plug wire off or something like that.

Poor bsfc numbers are simply the result of using a lot of fuel....... and not efficiently converting it to hp.

Edit- just read thru mbairds old dyno thread.

His engine was overfilled with oil by 2.75qts....... which I have personally seen cause big power losses.

I listed a bunch of basic things to check. Did you make sure the firing order was correct?

Jean Genibrel

Member

t does if you set the cam off the TDC that may be innacurateI doubt he put an old used damper on a new stroker. And the damper has zero effect on cam timing.

autoxcuda

Well-Known Member

- Joined

- Apr 6, 2007

- Messages

- 9,519

- Reaction score

- 5,044

t does if you set the cam off the TDC that may be innacurate

Do YOU degree a cam using the Vibration Dampener TDC ??

Everyone I've experienced uses a degree wheel and micrometer to piston setup.

autoxcuda

Well-Known Member

- Joined

- Apr 6, 2007

- Messages

- 9,519

- Reaction score

- 5,044

Bottom line there's a million things that can go wrong. Trying to diagnose every minute detail over the internet is an exercise in futility.

Some educated guesses based on available info (or info needed) to point the Original Poster in the right general direction are helpful to him. Seems the general consensus is this motor is down at least 30-50 hp.

Please read all the posts by Jim Ward within these 11 pages here that provide hard data on his motor.

Some educated guesses based on available info (or info needed) to point the Original Poster in the right general direction are helpful to him. Seems the general consensus is this motor is down at least 30-50 hp.

Please read all the posts by Jim Ward within these 11 pages here that provide hard data on his motor.

Last edited:

autoxcuda

Well-Known Member

- Joined

- Apr 6, 2007

- Messages

- 9,519

- Reaction score

- 5,044

Well your gasket bore is smaller than the block bore and piston diameter according to your build sheet .

I think that first sheet are theoretical calcs from the seller? (CNC Motorsports?) of the Stroker Kit. Notice is says, "Installation Instructions" on top.

Maybe those calcs are based on Buyer info or generic values. Jim Ward would know details.

The piston diameter on that first sheet is 4.080 (?hard to read, but calcs to 418").

But on the piston build sheet, it's 4.100

Also weird, the Kit sheet says IC745 Icon pistons, but the piston sheet says Racetec Pistons. ???

stock cast iron heads no porting, stock cast iron intake no porting, .455 lift cam but a lot of duration, stock TQ carb and stock type pistons. Just rebutting where someone said you HAVE to have better heads big cam and the best intake to get 500 HP. Not needed just sort out what you have. My guess, cam and distributor out of sync.Yea, but the duration and other cam events are not stock. Bunch of other stuff going on there. Dedicated race car.

This is more of hot street build.

-

Similar threads

- Replies

- 6

- Views

- 441

- Replies

- 2

- Views

- 2K

- Replies

- 11

- Views

- 1K